Blog

Just trust us, we are insiders of SiC here in China.

Behind us are the experts from the CAS, Chinese Academy of Sciences, and the export alliance of 10+ Sic plants, we have more resources and technical support than other peers.

About SicSino

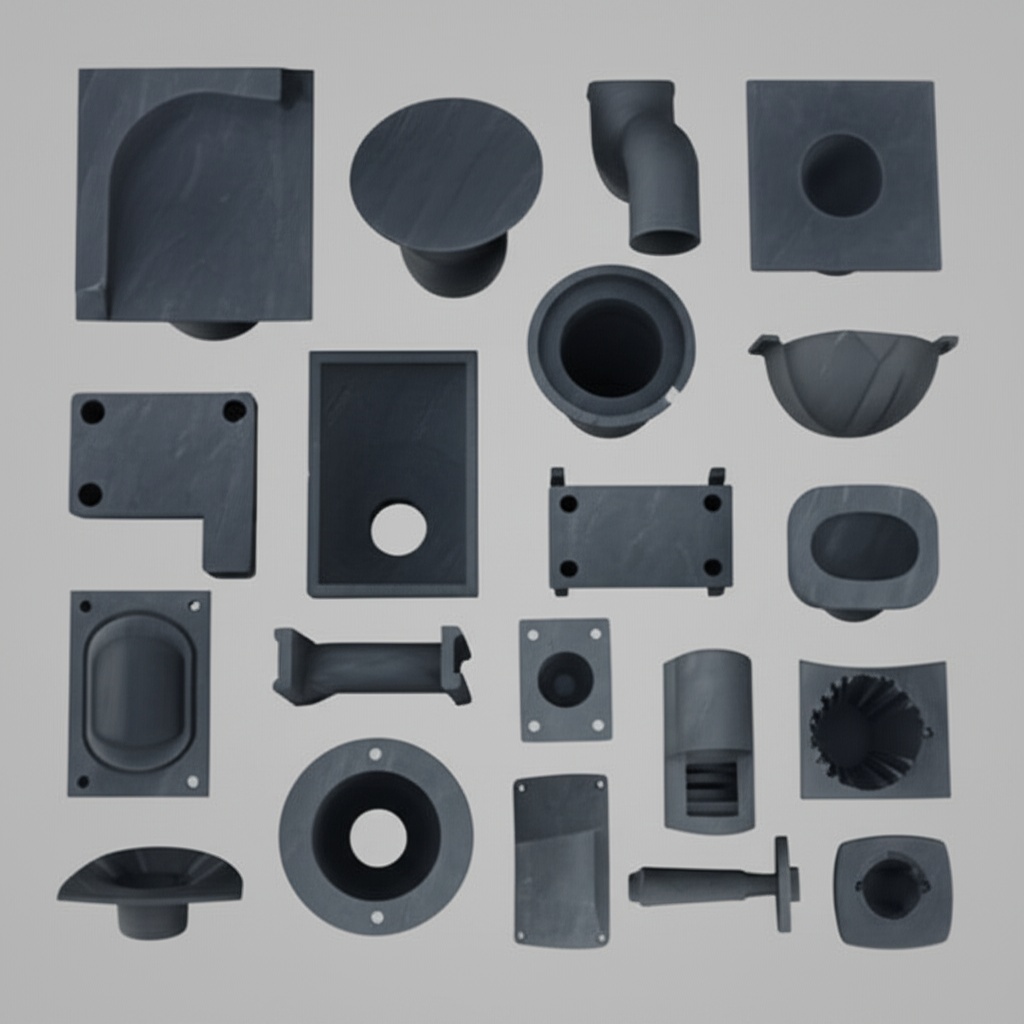

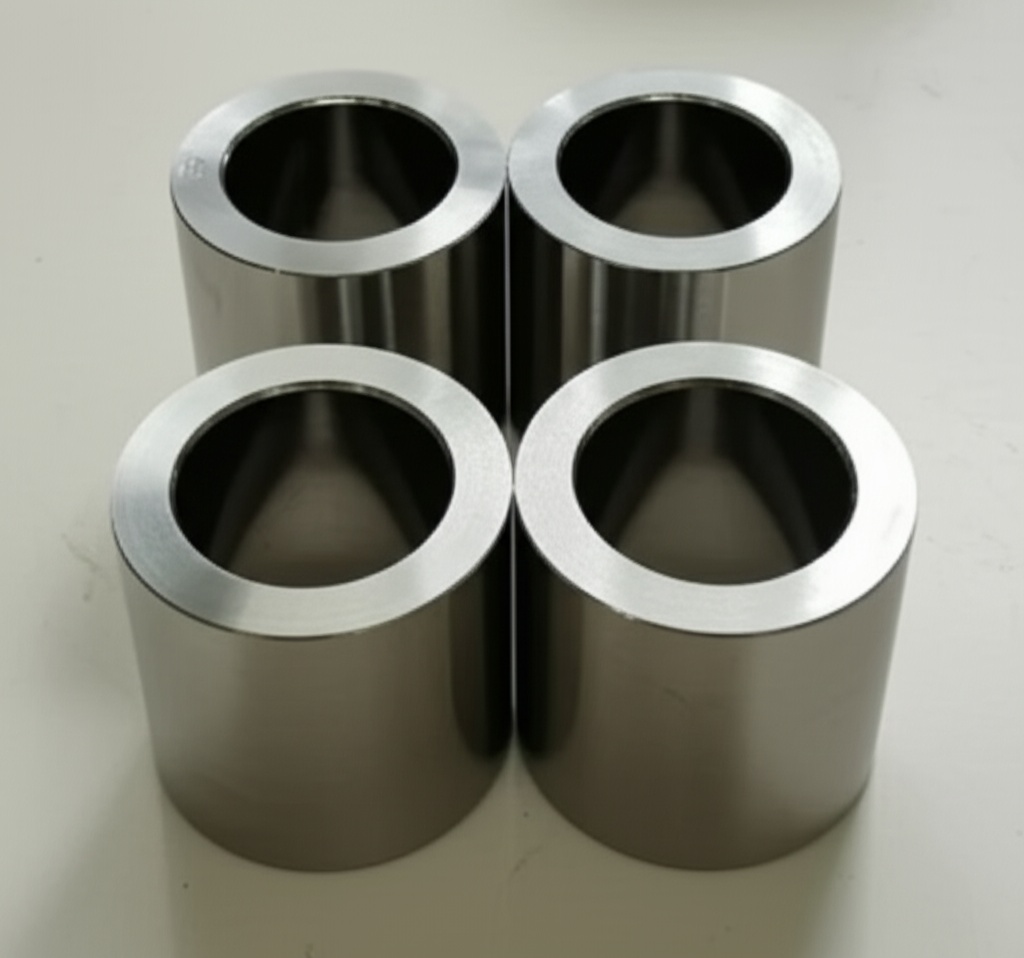

CAS new materials(SicSino) is a national-level platform backed by the national technology transfer center of the CAS(Chinese Academy of Sciences). It has formed an export alliance with10+ local SiC plants, and jointly engage in international trade through this platform (SicSino), enabling customized SiC parts and technologies to export overseas.

Main Materials

About Us

Contacts

© Weifang Sicsino All Rights Reserved.