S. Korean SiC Products for Your Success

シェア

S. Korean SiC Products for Your Success

In today’s rapidly advancing industrial landscape, the demand for materials that can withstand extreme conditions while delivering superior performance is paramount. Among these, **custom silicon carbide (SiC) products** stand out as a game-changer, offering unparalleled properties for a diverse range of critical applications. This blog post delves into the world of SiC, exploring its profound impact, particularly in South Korea, and guiding you through the considerations for leveraging this remarkable material in your next project.

カスタム炭化ケイ素製品とは?

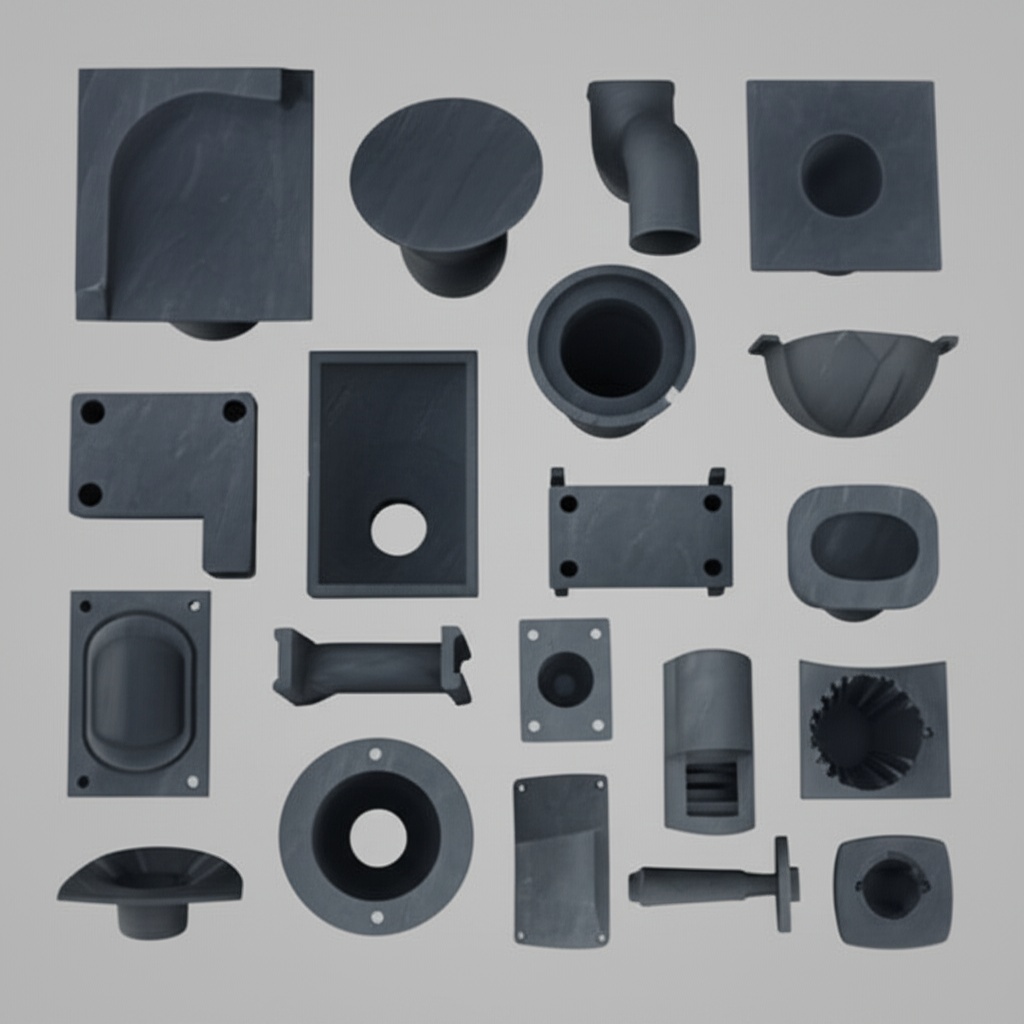

Custom silicon carbide products are engineered ceramic components tailored to specific industrial requirements. Unlike off-the-shelf solutions, custom SiC parts are designed and manufactured to precise specifications, ensuring optimal performance, longevity, and efficiency in demanding environments. This customization allows for intricate geometries, specific material compositions, and tailored surface finishes, making them indispensable in applications where standard materials simply fall short. From high-temperature furnace components to wear-resistant pump seals, the versatility of custom SiC is virtually limitless. The ability to precisely control the material’s properties—such as its exceptional hardness, high thermal conductivity, and chemical inertness—makes it a preferred choice for engineers and procurement managers seeking robust and reliable solutions.

業界における炭化ケイ素の主な用途

The unique properties of silicon carbide make it an indispensable material across a vast spectrum of industries. Its ability to perform reliably under harsh conditions, including high temperatures, corrosive environments, and abrasive wear, makes it a top choice for critical components. Below is a detailed look at some of the key sectors benefiting from SiC technology:

- 半導体製造: SiC is vital for wafer processing equipment, susceptors, and various components exposed to aggressive plasmas and high temperatures. Its high purity and thermal stability ensure consistent process conditions, crucial for producing advanced microchips.

- 自動車産業: From power electronics in electric vehicles (EVs) to braking systems and engine components, SiC’s superior thermal management and wear resistance contribute to enhanced efficiency, reduced weight, and improved durability.

- 航空宇宙: For aircraft and spacecraft, SiC components are used in high-temperature engine parts, thermal protection systems, and structural elements where lightweight and extreme heat resistance are critical.

- パワーエレクトロニクス SiC devices enable higher power density, increased efficiency, and smaller form factors in inverters, converters, and power modules, driving advancements in renewable energy, industrial drives, and grid infrastructure.

- 再生可能エネルギー: Essential for solar inverters and wind turbine converters, SiC enhances energy conversion efficiency and reliability, playing a crucial role in the transition to sustainable energy.

- 冶金: SiC is used in furnace linings, crucibles, and heat exchangers due to its excellent thermal shock resistance and high-temperature strength, improving efficiency and lifespan in metal processing.

- 防衛請負業者: For armor plating, missile components, and high-performance sensors, SiC offers exceptional hardness, lightweight properties, and thermal stability crucial for demanding defense applications.

- 化学処理会社: SiC’s chemical inertness makes it ideal for pump components, valves, and heat exchangers handling corrosive acids and alkalis, ensuring long-term reliability and reduced downtime.

- LED製造: SiC substrates are increasingly used for high-brightness LEDs, offering superior thermal management and crystal quality, leading to more efficient and durable lighting solutions.

- 産業機器メーカー: In pumps, seals, bearings, and nozzles, SiC provides superior wear resistance and extended service life, reducing maintenance costs and increasing operational efficiency in harsh industrial environments.

- 電気通信会社: SiC is used in high-frequency, high-power amplifiers for base stations and satellite communication systems, enabling more reliable and efficient signal transmission.

- 石油ガス会社: For downhole tools, drilling components, and high-pressure seals, SiC’s extreme hardness and corrosion resistance ensure durability and performance in challenging extraction environments.

- 医療機器メーカー: SiC’s biocompatibility and sterilizability make it suitable for surgical instruments, implantable devices, and medical equipment requiring high precision and resistance to wear and corrosion.

- 鉄道輸送会社: In traction systems, braking components, and power converters, SiC contributes to energy efficiency, reduced weight, and enhanced reliability of trains.

- 原子力会社: SiC is being explored for fuel cladding and structural components in advanced nuclear reactors due to its excellent radiation resistance and high-temperature stability, improving safety and efficiency.

なぜカスタム炭化ケイ素を選ぶのか?

The decision to opt for custom silicon carbide over standard materials or alternative ceramics is driven by a compelling set of advantages that directly translate into improved performance, longevity, and cost-effectiveness in demanding applications:

- 優れた耐熱性: SiC maintains its strength and integrity at extremely high temperatures, far exceeding many metals and other ceramics. This makes it ideal for high-temperature processing and thermal management.

- 優れた耐摩耗性: Its inherent hardness, second only to diamond, provides outstanding resistance to abrasion and erosion, extending the lifespan of components in abrasive environments.

- 化学的不活性: SiC is highly resistant to a wide range of corrosive chemicals, including strong acids and bases, making it suitable for chemical processing and other aggressive environments.

- 高い熱伝導性: This property allows SiC to efficiently dissipate heat, crucial for power electronics and other applications where thermal management is critical.

- 軽量SiC構造 SiC offers excellent mechanical strength while remaining relatively lightweight, a vital advantage for aerospace and automotive applications.

- 耐熱衝撃性: It can withstand rapid temperature changes without cracking or degradation, ensuring reliability in thermally cyclic environments.

- より優れた熱伝達でより高い温度で動作する能力は、より軽量なコンポーネント(薄肉の窯道具など)を設計する可能性と組み合わされて、大幅なエネルギー節約につながる可能性があります。より速いサイクル時間と削減された熱質量は、処理された製品の単位あたりの燃料または電気消費量の削減に貢献します。 Tailoring the design and composition of SiC components ensures they precisely meet the unique demands of specific applications, leading to optimized performance and reduced material waste.

推奨されるSiCグレードと組成

Silicon carbide is not a monolithic material; it comes in various grades, each with distinct properties optimized for different applications. Understanding these compositions is key to selecting the right material for your specific needs:

| SiCグレード/タイプ | 主な特徴 | 代表的なアプリケーション |

|---|---|---|

| 反応焼結SiC(RBSC) | High strength, excellent wear and corrosion resistance, good thermal shock resistance, fine-grained structure, easily formed into complex shapes. | Kiln furniture, pump components, wear parts, heat exchangers, mechanical seals. |

| 焼結SiC(SSC) | Extremely high hardness, exceptional strength at high temperatures, superior corrosion and wear resistance, near-theoretical density. | Ball valve components, semiconductor processing equipment, bearings, nozzles, nuclear applications. |

| 窒化結合SiC(NBSC) | Good thermal shock resistance, high strength, excellent abrasion resistance, lower density than RBSC or SSC. | Refractory applications, furnace components, wear linings. |

| 再結晶SiC(ReSiC) | High purity, excellent thermal conductivity, low thermal expansion, good thermal shock resistance. | High-temperature furnace elements, semiconductor susceptors, laboratory equipment. |

| 化学蒸着SiC(CVD SiC) | Extremely high purity, near-perfect theoretical density, isotropic properties, highly conformal coatings. | Semiconductor wafer carriers, optical components, high-precision fixtures. |

SiC製品の設計に関する考慮事項

Designing custom silicon carbide components requires careful consideration of the material’s unique properties to ensure manufacturability and optimal performance. Engineers must account for several factors to achieve successful outcomes:

- 形状の制限: While SiC can be formed into complex shapes, intricate features, very thin walls, and sharp internal corners can be challenging and costly to produce. Simple geometries are often preferred for manufacturability.

- 壁の厚さ: Maintaining consistent wall thickness throughout the design is crucial for uniform sintering and to minimize the risk of warping or cracking during processing.

- ストレスポイント: Identify and mitigate potential stress concentration points. SiC, like other ceramics, is brittle and can be susceptible to fracture under tensile stress. Radii should be incorporated at corners and transitions to reduce stress.

- 公差: While high precision is achievable, excessively tight tolerances can significantly increase manufacturing costs and lead times. Design for the loosest possible tolerances that still meet functional requirements.

- 素材グレードの選択: As discussed, choosing the appropriate SiC grade (e.g., RBSC, SSC) based on the application’s specific thermal, mechanical, and chemical demands is fundamental.

- 組み立てと接合: Consider how the SiC component will be integrated into a larger assembly. Methods like brazing, mechanical fastening, or adhesive bonding should be planned for in the design phase.

公差、表面仕上げ、および寸法精度

Achieving the desired tolerance and surface finish in custom SiC products is critical for their functional performance, particularly in high-precision applications. Due to the inherent hardness of silicon carbide, machining and finishing are typically performed using diamond tools, which can impact cost and lead time.

- 達成可能な公差: While standard ceramic manufacturing might achieve tolerances of $pm 0.5%$ or $pm 0.1$ mm (whichever is greater), advanced finishing techniques can achieve much tighter tolerances, often down to $pm 0.005$ mm for critical dimensions. However, tighter tolerances always come with increased cost and complexity.

- 表面仕上げオプション:

- 表面は比較的粗く、初期SiC粉末の粒子サイズと焼結プロセスを反映したテクスチャがあります。一般的なRa(平均粗さ)値は、1μm〜5μm以上の範囲になる可能性があります。これは、窯道具のような用途では許容される場合があります。 This is the most economical finish, with a rougher appearance. Suitable for non-critical surfaces.

- グラウンド仕上げ: Achieved through diamond grinding, this provides a smoother, more uniform surface. Common for mating surfaces or where dimensional accuracy is important.

- ラップ/研磨仕上げ: For the highest precision and smoothest surface (e.g., optical applications, mechanical seals), lapping and polishing with fine diamond slurries can achieve mirror-like finishes and extremely tight flatness.

- 寸法精度: The overall dimensional accuracy depends on the chosen manufacturing process (e.g., pressing, extrusion, slip casting) and subsequent machining operations. For highly precise components, post-sintering grinding and lapping are almost always required.

SiCコンポーネントのポストプロセスニーズ

After the initial firing or sintering, many SiC components undergo further post-processing steps to achieve their final desired properties, dimensions, and surface finishes. These steps are crucial for enhancing performance and durability:

- 研磨: Precision grinding with diamond wheels is essential for achieving tight dimensional tolerances and specific surface finishes on SiC components. This is often required for critical mating surfaces or where precise fits are necessary.

- ラッピングとポリッシング: For applications demanding extremely flat and smooth surfaces, such as mechanical seals, optical components, or semiconductor wafer carriers, lapping and polishing with fine abrasive slurries (typically diamond) are employed.

- 表面コーティング: In some cases, additional coatings (e.g., CVD SiC, pyrolytic carbon, or specialty ceramics) can be applied to further enhance properties like corrosion resistance, erosion resistance, or electrical conductivity/insulation.

- シーリング: For porous SiC grades (e.g., some RBSC variants), sealing might be necessary for gas or liquid impermeability in certain applications. This can involve impregnation with polymers or glass.

- 接合/接合: SiC components may need to be joined to other SiC parts or dissimilar materials using techniques like brazing, diffusion bonding, or adhesive bonding, often requiring specialized surface preparation.

- 検査と品質管理: Rigorous post-processing inspection, including dimensional checks, non-destructive testing (NDT) like ultrasonic testing or X-ray inspection, and surface finish evaluation, ensures the components meet specifications.

一般的な課題とそれらを克服する方法

炭化ケイ素は比類のない利点を提供しますが、この高度なセラミック材料を扱うことは、専門知識と特殊な製造能力を必要とする特定の課題を提示します。

- 脆さ: Like most ceramics, SiC is inherently brittle, meaning it can fracture under tensile stress or impact.

- 克服: Design components with generous radii, avoid sharp corners, and minimize stress concentrations. Proper handling and mounting procedures are also critical.

- 機械加工の複雑さ: SiCの極度の硬度により、機械加工が困難でコストがかかり、特殊なダイヤモンド工具と技術が必要になります。

- 克服: Design for manufacturability by simplifying geometries where possible, and work with suppliers possessing advanced diamond grinding and lapping capabilities.

- 高い焼結温度: Achieving full density in SiC often requires extremely high sintering temperatures (over $2000^circtext{C}$), which can lead to part distortion or require specialized equipment.

- 克服: Utilize advanced firing techniques and precise temperature control. Selecting appropriate SiC grades (e.g., reaction-bonded SiC) can sometimes mitigate the need for extremely high sintering temperatures.

- 熱衝撃感度(一部のグレードの場合): While overall good, some SiC grades can be susceptible to thermal shock if subjected to very rapid and extreme temperature changes without proper design.

- 克服: Choose SiC grades with excellent thermal shock resistance, design for uniform heating/cooling, and consider pre-heating or slow ramp rates where possible.

- コスト: Custom SiC components can be more expensive than conventional materials due to raw material costs, complex manufacturing processes, and specialized tooling.

- 克服: Optimize designs for manufacturability, evaluate if a less expensive SiC grade can meet requirements, and focus on the total cost of ownership, considering SiC’s extended lifespan and performance benefits.

適切なSiCサプライヤーの選び方

Selecting a reliable and capable custom silicon carbide supplier is paramount to the success of your project. This decision significantly impacts the quality, performance, and cost-effectiveness of your SiC components. Here are key criteria to consider:

- 技術的能力と専門知識:

- 材料科学の知識: Does the supplier possess deep understanding of various SiC grades (RBSC, SSC, NBSC, CVD SiC) and their optimal applications?

- 製造性のための設計(DFM): Can they provide guidance on optimizing your design for SiC production, reducing costs and improving quality?

- Advanced Machining and Finishing: Do they have state-of-the-art diamond grinding, lapping, and polishing capabilities for high-precision components?

- 品質管理と認証:

- Accreditation: Look for ISO 9001 certification or other relevant industry standards that demonstrate a commitment to quality management.

- Inspection Capabilities: Do they offer robust in-process and final inspection, including dimensional accuracy checks, NDT, and material analysis?

- 材料オプションとカスタマイズ:

- SiCグレードの範囲: A diverse portfolio of SiC types allows for greater flexibility in material selection to match your specific application needs.

- カスタマイズ・サポート: Can they accommodate unique geometries, specific property requirements, and specialized post-processing? For in-depth support on customization, please visit our カスタマイズサポートページをご覧ください。.

- 生産能力とリードタイム:

- Assess their ability to meet your required volumes and delivery schedules, especially for large-scale or time-sensitive projects.

- 業界経験:

- Prefer suppliers with a proven track record in your specific industry (e.g., semiconductors, aerospace, power electronics), indicating an understanding of your unique challenges. You can explore our successful application cases here.

- 顧客サービスとコミュニケーション:

- Effective communication, responsiveness, and transparent reporting throughout the project lifecycle are vital.

When considering a supplier, it’s worth noting the significant advancements in silicon carbide manufacturing, particularly in China. Here is the hub of China’s silicon carbide customizable parts factories, with Weifang City being a prominent center. This region is home to over 40 silicon carbide production enterprises, collectively accounting for more than 80% of the nation’s total SiC output.

私たちは、 CAS New Materials(SicSino), have played a pivotal role in this development. Since 2015, we have been introducing and implementing advanced silicon carbide production technology, assisting local enterprises in achieving large-scale production and significant technological advancements in product processes. We have been a direct witness to the emergence and ongoing development of the local silicon carbide industry.

CAS New Materials (SicSino) belongs to CAS (Weifang) Innovation Park, an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences (CAS). As a national-level innovation and entrepreneurship service platform, our park integrates innovation, entrepreneurship, technology transfer, venture capital, incubation, acceleration, and scientific and technological services.

Leveraging the robust scientific, technological capabilities, and talent pool of the Chinese Academy of Sciences (CAS), and backed by the CAS National Technology Transfer Center, CAS New Materials (SicSino) serves as a crucial bridge. We facilitate the integration and collaboration of essential elements in the transfer and commercialization of scientific and technological achievements. Furthermore, we have established a comprehensive service ecosystem that spans the entire spectrum of the technology transfer and transformation process.

With a domestic top-tier professional team specializing in customized production of silicon carbide products, we have supported over 482 local enterprises with our technologies. Our wide array of technologies, encompassing materials, processes, design, measurement, and evaluation, along with an integrated process from raw materials to finished products, enables us to meet diverse customization needs. This allows us to offer you higher-quality, cost-competitive customized silicon carbide components from China.

Beyond supplying components, we are also committed to assisting you in establishing a specialized factory. If you need to build a professional silicon carbide products manufacturing plant in your country, CAS New Materials (SicSino) can provide you with the technology transfer for professional silicon carbide production. We offer a full range of services, including factory design, procurement of specialized equipment, installation and commissioning, and trial production, effectively providing a turnkey project solution. This ensures you can own a professional silicon carbide products manufacturing plant with a more effective investment, reliable technology transformation, and a guaranteed input-output ratio. Learn more about our 技術移転サービス.

コ

Understanding the factors that influence the cost and lead time of custom silicon carbide components is essential for effective project planning and budgeting:

コストドライバー:

- 材料グレード: Different SiC grades have varying raw material costs and processing complexities. Sintered SiC (SSC) and CVD SiC, for example, are typically more expensive than Reaction-Bonded SiC (RBSC) due to higher purity or more complex manufacturing.

- 部品の複雑さ: Intricate geometries, tight tolerances, and fine surface finishes significantly increase manufacturing costs due to the need for more specialized tooling, longer machining times, and more advanced finishing processes.

- ボリューム: As with most manufactured goods, higher production volumes generally lead to lower per-unit costs due to economies of scale in raw material purchasing and production setup.

- 後処理の要件: Extensive grinding, lapping, polishing, or coating significantly add to the overall cost.

- 試験と検査: Rigorous quality control and advanced testing (e.g., NDT, material characterization) can also contribute to the final price.

リードタイムに関する考慮事項:

- 設計の複雑さ: Highly complex designs require more time for design review, tooling fabrication, and manufacturing process development.

- 材料の入手可能性: The availability of specific SiC raw materials or pre-forms can influence lead times.

- 生産能力: A supplier’s current workload and available manufacturing capacity will directly impact how quickly they can begin and complete your order.

- 後処理: Specialized finishing operations like precision grinding, lapping, or coating extend the overall production time.

- 品質保証: Comprehensive testing and inspection protocols, while essential for quality, also add to the lead time.

よくある質問(FAQ)

- Q1: What are the primary benefits of using silicon carbide over traditional metals or other ceramics?

- A1: Silicon carbide offers superior performance in extreme environments due to its exceptional hardness, high thermal conductivity, excellent wear resistance, and chemical inertness. It maintains mechanical integrity at temperatures where metals would deform or melt, and it resists corrosion from aggressive chemicals better than many other ceramics.

- Q2: Can silicon carbide be easily machined into complex shapes?

- A2: SiC is extremely hard, making traditional machining very difficult and costly. Most shaping is done in the green (unfired) state, followed by high-temperature sintering. Precision shaping of fully dense SiC components typically requires advanced diamond grinding and lapping techniques, which allow for high dimensional accuracy and intricate geometries, albeit at a higher cost.

- Q3: How does the cost of custom SiC products compare to standard ceramic components?

- A3: Custom silicon carbide components generally have a higher upfront cost than standard ceramic parts or traditional metals due to the specialized raw materials, complex manufacturing processes, and demanding post-processing requirements. However, their extended lifespan, superior performance, and reduced maintenance needs often result in a lower total cost of ownership in demanding applications.

- Q4: Is SiC suitable for electrical insulation applications?

- A4: While SiC is a semiconductor and can be doped to achieve various electrical properties, in its purest forms, it exhibits good electrical insulation characteristics, especially at high temperatures. For critical insulation needs, specific grades and processing methods are chosen to maximize resistivity. CVD SiC is particularly noted for its insulating properties.

- Q5: What industries in South Korea are currently seeing the most growth in SiC adoption?

- A5: South Korea is a global leader in semiconductor and power electronics manufacturing, making these two sectors significant drivers of SiC adoption. The growing electric vehicle market and advancements in renewable energy also contribute to increasing demand for SiC components in the automotive and energy industries.

結論

Custom silicon carbide products are not merely components; they are critical enablers for innovation and efficiency in the most demanding industrial environments. Their unique blend of thermal, mechanical, and chemical properties positions them as indispensable materials for engineers, procurement managers, and technical buyers seeking reliable, high-performance solutions. From enhancing the efficiency of power electronics in South Korea’s burgeoning EV market to ensuring the precision of semiconductor manufacturing, SiC is at the forefront of advanced materials science.

By understanding the nuances of SiC grades, design considerations, and the importance of selecting a knowledgeable supplier, you can unlock the full potential of this remarkable material. Partnering with a company like CAS New Materials (SicSino), with its deep technological roots in the heart of China’s SiC manufacturing hub and its commitment to technology transfer, offers a trusted pathway to securing high-quality, cost-competitive custom silicon carbide components. For further inquiries or to discuss your specific needs, please feel free to 特定のニーズについて話し合い、詳細をご覧ください。. Invest in custom SiC, and invest in your success.