Mastering SiC Manufacturing for Optimal Market Results

Share

Mastering SiC Manufacturing for Optimal Market Results

Introduction: The Essential Role of Custom Silicon Carbide in Modern Industry

In the landscape of advanced materials, custom silicon carbide (SiC) products stand out for their exceptional properties and versatility. Silicon carbide, a compound of silicon and carbon, is a leading technical ceramic renowned for its hardness, thermal conductivity, and resistance to wear, corrosion, and high temperatures. As industries push the boundaries of performance and efficiency, the demand for components that can withstand extreme conditions has surged. Standard off-the-shelf parts often fall short of meeting the precise requirements of these demanding applications. This is where custom SiC components become indispensable, offering tailored solutions that optimize performance, extend service life, and drive innovation across a multitude of sectors.

From the ultra-pure environments of semiconductor manufacturing to the harsh realities of metallurgical furnaces and the critical demands of aerospace engineering, custom silicon carbide parts are enabling technological advancements. Their ability to be engineered to specific geometries, tolerances, and material compositions makes them crucial for OEMs and technical buyers seeking a competitive edge. Understanding the nuances of SiC manufacturing is paramount for businesses looking to leverage its full potential for optimal market results.

Key Industrial Applications of Custom SiC Components

The unique combination of properties exhibited by silicon carbide makes it a material of choice for a vast array of industrial applications. Its widespread adoption is a testament to its reliability and performance in challenging environments. Here’s an exploration of how custom SiC is utilized across key industries:

- Semiconductor Manufacturing: SiC components such as wafer handling tools, process chamber parts (etch rings, showerheads), and susceptors are critical due to their high purity, thermal stability, and resistance to plasma erosion. These properties ensure minimal contamination and consistent performance in chip fabrication.

- Automotive: Used in high-performance braking systems, wear-resistant seals and bearings for pumps, and increasingly in power electronics for electric vehicles (EVs) due to its superior thermal management and efficiency at high voltages and temperatures.

- Aerospace & Defense: Components like mirror substrates for optical systems, rocket nozzles, heat exchangers, and armor plating benefit from SiC’s light weight, high stiffness, thermal shock resistance, and durability. Examples of such advanced applications demonstrate the material’s capabilities.

- Power Electronics: SiC-based diodes, MOSFETs, and power modules are revolutionizing power conversion and management by enabling higher switching frequencies, temperatures, and efficiencies, leading to smaller and more reliable devices.

- Renewable Energy: In solar and wind power systems, SiC inverters improve energy conversion efficiency and durability, contributing to more effective and sustainable energy generation.

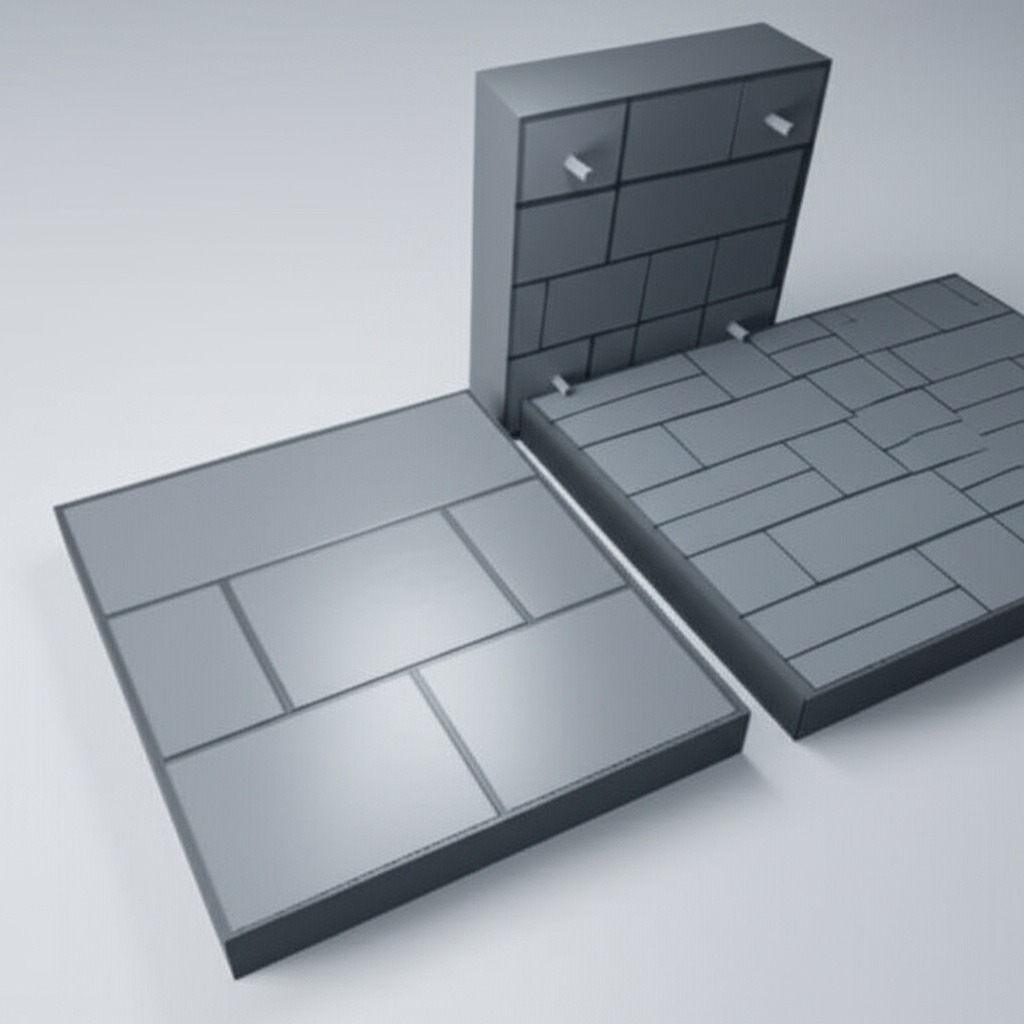

- Metallurgy & High-Temperature Furnaces: Kiln furniture (beams, rollers, setters, plates), crucibles, thermocouple protection tubes, and burner nozzles made from SiC withstand extreme temperatures, thermal cycling, and corrosive atmospheres, ensuring longer life and energy savings.

- Chemical Processing: Seals, pump components, valves, and heat exchanger tubes made from SiC offer excellent chemical inertness and wear resistance, crucial for handling aggressive chemicals and abrasive slurries.

- LED Manufacturing: SiC substrates are used for growing GaN layers in high-brightness LEDs, offering good lattice matching and thermal conductivity for improved light output and device longevity.

- Industrial Machinery: Wear parts, mechanical seals, nozzles for abrasive blasting, and grinding media benefit from SiC’s extreme hardness and wear resistance, leading to reduced downtime and maintenance costs.

- Oil and Gas: Components in downhole tools, pumps, and valves require materials that can withstand high pressures, abrasive materials, and corrosive environments – conditions where SiC excels.

- Medical Devices: Biocompatible grades of SiC are being explored for wear-resistant implantable devices and surgical tools.

- Rail Transportation: SiC is used in power electronics for traction control systems, contributing to more efficient and reliable train operations.

- Nuclear Energy: SiC and SiC-composites are considered for structural components and fuel cladding in next-generation nuclear reactors due to their stability under irradiation and high temperatures.

The adaptability of custom SiC fabrication allows manufacturers to produce highly specialized parts catering to the unique demands of each of these industries, ensuring optimal performance and longevity.

The Strategic Advantages of Opting for Custom Silicon Carbide Solutions

While standard SiC components are available, choosing custom silicon carbide solutions offers significant strategic advantages for businesses aiming for peak performance and innovation. Customization allows for parts to be perfectly aligned with specific application requirements, rather than compromising with off-the-shelf products. Here are key benefits:

- Optimized Performance: Custom designs ensure that SiC components precisely fit the intended application’s geometry, load requirements, and operating environment. This tailored approach maximizes efficiency, reliability, and overall system performance.

- Enhanced Thermal Management: Silicon carbide boasts excellent thermal conductivity and stability at high temperatures. Customization can optimize heat dissipation paths and thermal shock resistance, critical for applications like power electronics, furnace components, and heat exchangers.

- Superior Wear and Abrasion Resistance: SiC is one of the hardest commercially available materials. Custom-designed wear parts can significantly extend the service life of equipment operating in abrasive or high-friction environments, reducing maintenance costs and downtime.

- Exceptional Chemical Inertness: Custom SiC parts can be engineered to resist a wide range of corrosive chemicals, acids, and alkalis, making them ideal for demanding chemical processing and oil and gas applications.

- Design Flexibility: Advanced manufacturing techniques allow for the creation of complex SiC geometries that might not be achievable with other materials or standard parts. This enables innovative product designs and solutions to challenging engineering problems.

- Material Grade Selection: Customization allows for the selection of the most appropriate SiC grade (e.g., reaction-bonded, sintered, nitride-bonded) and composition to match the specific mechanical, thermal, and electrical requirements of the application.

- Improved System Integration: Components designed to exact specifications integrate more seamlessly into larger systems, potentially reducing assembly time and improving the overall quality and reliability of the final product.

- Competitive Advantage: By leveraging custom SiC components, companies can develop proprietary solutions that offer superior performance or longevity, providing a distinct competitive edge in the market.

- Long-Term Cost Savings: While initial costs for custom parts might be higher than standard ones, the extended lifespan, reduced maintenance, and improved efficiency often lead to lower total cost of ownership over time.

Investing in custom SiC solutions is an investment in quality, durability, and tailored performance, enabling industries to push operational boundaries and achieve new levels of productivity.

Navigating Silicon Carbide Grades: A Guide to Material Selection

Selecting the appropriate grade of silicon carbide is crucial for ensuring optimal performance and cost-effectiveness in any given application. Different manufacturing processes result in SiC materials with varying properties. Understanding these distinctions is key for engineers and procurement professionals.

Here’s a look at common SiC grades and their characteristics:

| SiC Grade | Common Acronyms | Key Properties | Typical Applications |

|---|---|---|---|

| Reaction-Bonded Silicon Carbide | RBSC, SiSiC (Silicon Infiltrated Silicon Carbide) | Good mechanical strength, excellent wear and corrosion resistance, high thermal conductivity, relatively easy to form complex shapes, good thermal shock resistance, moderate cost. Contains some free silicon (typically 8-15%). | Kiln furniture, burner nozzles, wear liners, pump components, mechanical seals, heat exchangers. |

| Sintered Silicon Carbide | SSiC (Solid State Sintered or Pressureless Sintered), DDF-SiC (Direct Sintered) | Very high strength and hardness, excellent corrosion and erosion resistance, high thermal conductivity, maintains strength at very high temperatures (up to 1600°C+), high purity. More expensive than RBSC. | Bearings, seals, semiconductor processing equipment, ballistic armor, chemical processing components, nozzles. |

| Nitride-Bonded Silicon Carbide | NBSC | Good thermal shock resistance, high strength, good resistance to molten metals (especially aluminum), moderate wear resistance. Formed by bonding SiC grains with silicon nitride. | Furnace linings, thermocouple protection tubes, components for non-ferrous metal handling, kiln furniture. |

| Recrystallized Silicon Carbide | RSiC | High purity, excellent thermal shock resistance, high working temperatures (up to 1650°C), porous structure (can be CVD coated for sealing). | High-temperature kiln furniture, setters, radiant tubes, diffusion tubes. |

| Chemical Vapor Deposited Silicon Carbide | CVD-SiC | Extremely high purity (99.999%+), theoretically dense, excellent chemical and erosion resistance, very smooth surfaces achievable. Typically used as a coating or for thin, high-purity components. | Semiconductor wafer processing equipment (susceptors, rings), optical components, protective coatings. |

| Hot-Pressed Silicon Carbide | HPSiC | Very high density and strength, fine grain structure, excellent wear resistance. Expensive due to the manufacturing process. | Cutting tools, specialized wear parts, armor. |

| Silicon Carbide Matrix Composites | SiC/SiC, C/SiC | Enhanced fracture toughness compared to monolithic SiC, high temperature stability, damage tolerance. | Aerospace components (turbine engine parts, thermal protection systems), high-performance brakes. |

The choice of SiC grade depends on a careful evaluation of the application’s demands, including operating temperature, mechanical stresses, chemical environment, thermal shock conditions, and budget. Consulting with an experienced silicon carbide supplier is essential for making the right selection.

Critical Design Considerations for Manufacturing Custom SiC Products

Designing components for custom silicon carbide manufacturing requires a different approach than designing with metals or plastics. SiC’s inherent hardness and brittleness necessitate careful consideration of several factors to ensure manufacturability, performance, and cost-effectiveness.

- Understand Material Properties: Designers must be intimately familiar with the specific SiC grade’s properties, particularly its tensile strength, compressive strength, fracture toughness, and thermal expansion coefficient. SiC is significantly stronger in compression than in tension.

- Geometry and Complexity:

- Simplify designs where possible: Complex features like sharp internal corners, thin walls, and abrupt changes in cross-section can create stress concentrations and make manufacturing difficult and expensive.

- Avoid sharp edges and corners: Generous radii should be used to minimize stress and reduce the risk of chipping or cracking during manufacturing or use.

- Wall thickness: Maintain uniform wall thickness to prevent distortion during sintering or firing. Minimum achievable wall thickness depends on the manufacturing process and overall part size.

- Manufacturing Process Limitations: The chosen forming method (e.g., pressing, slip casting, extrusion, additive manufacturing) will influence design possibilities. For instance, pressing is suitable for simpler shapes, while slip casting allows for more complex geometries. Discussing design feasibility with the manufacturer early is crucial.

- Tolerances: While SiC can be machined to tight tolerances, this often involves diamond grinding, which can be costly. Specify only critical tolerances to manage costs. Typical “as-sintered” tolerances are wider than machined tolerances.

- Joining and Assembly: If the SiC component needs to be joined to other parts (SiC or other materials), the design must accommodate the joining method (e.g., brazing, mechanical fastening, shrink fitting). Differential thermal expansion must be considered.

- Stress Points and Load Distribution: Identify areas of high stress and design to mitigate them. Ensure loads are distributed as evenly as possible. Consider finite element analysis (FEA) for complex or critical components to predict stress distributions.

- Surface Finish Requirements: Specify the required surface finish. Highly polished surfaces may be needed for sealing applications or optical components but add to the cost.

- Shrinkage: SiC parts undergo significant shrinkage during sintering (typically 15-20%). Designs must account for this shrinkage to achieve the desired final dimensions. This is primarily the responsibility of the manufacturer but understanding it helps in design discussions.

- Cost Implications: Design choices directly impact cost. Simpler designs, looser tolerances (where acceptable), and consideration of manufacturing capabilities can lead to more economical solutions.

Early collaboration between the design engineer and the SiC manufacturer is paramount. This collaborative approach ensures that the design is optimized for both performance and manufacturability, ultimately leading to a successful custom SiC product.

Achieving Precision: Tolerance, Surface Finish, and Dimensional Accuracy in SiC Parts

For high-performance applications, particularly in industries like semiconductors, aerospace, and medical devices, the dimensional accuracy, tolerances, and surface finish of custom silicon carbide parts are critical. Achieving the required precision involves understanding the capabilities and limitations of SiC manufacturing and post-processing techniques.

Tolerances:

- As-Sintered Tolerances: After the initial forming and sintering processes, SiC components will have certain dimensional variations. These “as-sintered” tolerances are typically in the range of ±0.5% to ±2% of the dimension, depending on the SiC grade, part size, complexity, and manufacturing process. For many industrial applications, as-sintered tolerances are acceptable and offer a cost-effective solution.

- Machined Tolerances: When tighter tolerances are required, SiC parts undergo precision grinding using diamond tooling. This allows for much finer control over dimensions. Standard machined tolerances can be as tight as ±0.025 mm (±0.001 inches), and in some specialized cases, even tighter tolerances down to micrometers can be achieved. However, achieving very tight tolerances significantly increases machining time and cost.

Surface Finish:

- As-Fired Surface: The surface finish of an as-sintered SiC part is generally rougher than a machined surface. The typical Ra (average roughness) might range from 1 to 5 µm (40 to 200 µinches), depending on the SiC grade and forming method.

- Ground Surface: Grinding improves the surface finish significantly. A standard ground finish can achieve Ra values of 0.4 to 0.8 µm (16 to 32 µinches).

- Lapped and Polished Surfaces: For applications requiring ultra-smooth surfaces, such as mechanical seals, bearings, or optical components, lapping and polishing processes are employed. These processes can achieve exceptionally smooth surfaces with Ra values below 0.1 µm (4 µinches), and even down to Angstrom levels for optical applications. Polishing also enhances the material’s strength by removing surface flaws.

Dimensional Accuracy:

Dimensional accuracy refers to how closely the manufactured part conforms to the specified dimensions in the design. It is influenced by:

- The precision of the initial tooling (molds, dies).

- The consistency and control of the forming and sintering processes.

- The capability of the machining equipment and skill of the operators.

- The accuracy of metrology equipment used for inspection.

Key Considerations for Procurement Professionals and Engineers:

- Specify only necessary precision: Over-specifying tolerances or surface finishes can drastically increase costs without adding functional value. Clearly define critical features and their required precision.

- Discuss with supplier: Engage with your SiC supplier early in the design phase to understand their capabilities regarding tolerances and surface finishes for specific SiC grades and part geometries.

- Consider inspection methods: Ensure appropriate metrology and inspection methods are in place to verify the dimensional accuracy and surface finish of the supplied components.

Achieving the desired precision in custom SiC components is a balance between application requirements, manufacturing capabilities, and cost. A knowledgeable supplier can guide you in making informed decisions to meet your performance and budget targets.

Enhancing Performance: Essential Post-Processing for SiC Components

While the inherent properties of silicon carbide are exceptional, many applications benefit from or require post-processing steps to further enhance performance, meet precise specifications, or improve the durability of custom SiC components. These value-added processes transform a near-net-shape sintered part into a finished product ready for demanding industrial use.

Common post-processing techniques include:

- Grinding:

- Purpose: To achieve tight dimensional tolerances, specific geometric features (flats, slots, holes), and improved surface finish. Due to SiC’s extreme hardness, diamond grinding wheels are exclusively used.

- Process: Involves various grinding techniques like surface grinding, cylindrical grinding (ID/OD), and centerless grinding. CNC grinding allows for complex profiles and high precision.

- Outcome: Parts with precise dimensions (tolerances often in the micron range) and smoother surfaces than as-sintered parts.

- Lapping:

- Purpose: To produce very flat surfaces and extremely fine surface finishes, often required for sealing faces or mating components.

- Process: Parts are moved against a flat lapping plate coated with a diamond slurry. The abrasive action removes minute amounts of material, resulting in a super-smooth, flat surface.

- Outcome: Surfaces with Ra values typically below 0.2 µm, and exceptional flatness.

- Polishing:

- Purpose: To achieve mirror-like finishes, further reducing surface roughness beyond lapping. Critical for optical components, some semiconductor parts, and high-performance seals.

- Process: Uses finer diamond abrasives and specialized polishing pads, often in multiple stages.

- Outcome: Extremely smooth (Ra < 0.05 µm), reflective surfaces, which can also improve the mechanical strength by removing surface micro-cracks.

- Machining (Drilling, Milling):

- Purpose: To create features like holes, threads, or complex contours that couldn’t be formed during the initial shaping process.

- Process: Requires specialized diamond tooling and techniques like ultrasonic machining or laser machining for very hard SiC grades. Traditional machining is challenging and slow.

- Outcome: Precise features according to design specifications.

- Cleaning:

- Purpose: To remove any contaminants, machining residues, or fingerprints before packaging or further processing (like coating). Critical for high-purity applications (e.g., semiconductor).

- Process: May involve ultrasonic cleaning with specific solvents, deionized water rinses, and controlled drying environments.

- Outcome: Ultra-clean surfaces meeting application purity standards.

- Sealing/Impregnation:

- Purpose: For some porous SiC grades (like certain RSiC or NBSC), sealing the porosity can improve chemical resistance, reduce permeability, or enhance mechanical properties. Reaction-bonded SiC (RBSC) inherently has its porosity filled with silicon.

- Process: Impregnation with resins or other materials.

- Outcome: Reduced porosity, improved performance in specific chemical environments.

- Coatings:

- Purpose: To add specific functionalities, such as enhanced corrosion resistance, improved lubricity, or specific electrical properties. CVD-SiC coatings are often applied to graphite or other SiC grades for ultra-high purity surfaces in semiconductor applications.

- Process: Techniques like Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD) can apply thin, highly adherent coatings.

- Outcome: Enhanced surface properties tailored to the application.

The selection of post-processing steps depends heavily on the final application requirements, the chosen SiC grade, and cost considerations. Working with a full-service SiC provider capable of performing these intricate post-processing operations is crucial for obtaining high-quality, finished components.

Overcoming Manufacturing Challenges in Custom Silicon Carbide Production

The same properties that make silicon carbide an exceptional material for demanding applications—its extreme hardness, high-temperature stability, and chemical inertness—also present significant challenges during its manufacturing. Understanding and overcoming these challenges is key to producing high-quality custom SiC components reliably and cost-effectively.

Key manufacturing challenges include:

- Brittleness and Low Fracture Toughness:

- Challenge: SiC is a brittle ceramic, meaning it can fracture suddenly under tensile stress or impact without significant plastic deformation. This makes it susceptible to chipping or cracking during machining and handling.

- Mitigation:

- Careful design to minimize stress concentrations (e.g., using fillets and radii).

- Specialized machining techniques (e.g., diamond grinding with optimized parameters, avoiding excessive force).

- Controlled handling and packaging procedures.

- Development of SiC matrix composites (e.g., SiC/SiC) for applications requiring higher toughness.

- Machining Complexity and Cost:

- Challenge: Due to its extreme hardness (second only to diamond and boron carbide), SiC is very difficult and time-consuming to machine. This requires specialized diamond tooling, rigid machinery, and skilled operators, leading to higher machining costs compared to metals.

- Mitigation:

- Near-net shaping techniques (e.g., precision molding, slip casting, additive manufacturing) to minimize the amount of material that needs to be removed by machining.

- Optimizing grinding parameters (wheel speed, feed rate, depth of cut, coolant).

- Employing advanced machining processes like ultrasonic-assisted grinding or laser machining for specific features.

- Designing for manufacturability, avoiding overly complex features or unnecessarily tight tolerances.

- High Sintering Temperatures:

- Challenge: Most SiC grades require very high temperatures for sintering (often >2000°C), which necessitates specialized furnaces, controlled atmospheres (e.g., argon or vacuum), and significant energy consumption.

- Mitigation:

- Precise control of furnace temperature profiles and atmospheres to ensure consistent densification and microstructure.

- Use of sintering aids for some grades (like SSiC) to lower sintering temperatures or improve densification. Reaction bonding (for RBSC) occurs at lower temperatures but involves handling molten silicon.

- Energy-efficient furnace designs and operational practices.

- Shrinkage and Dimensional Control:

- Challenge: SiC parts undergo significant and sometimes non-uniform shrinkage during drying and sintering (typically 15-20% linearly). Predicting and controlling this shrinkage to achieve desired final dimensions and tolerances can be complex.

- Mitigation:

- Careful control of powder characteristics and green body formation.

- Accurate modeling and empirical data to predict shrinkage for specific geometries and processing conditions.

- Designing tooling to compensate for expected shrinkage.

- Iterative process adjustments based on dimensional measurements of sintered parts.

- Quality Control and Defect Detection:

- Challenge: Internal flaws such as pores, cracks, or inclusions can compromise the mechanical integrity of SiC components. Detecting these defects, especially in complex shapes, requires sophisticated non-destructive testing (NDT) methods.

- Mitigation:

- Stringent raw material quality control.

- Optimized forming and sintering processes to minimize defect formation.

- Employing NDT techniques such as X-ray radiography, ultrasonic testing, and fluorescent penetrant inspection.

- Microstructural analysis.

- Joining SiC to Itself or Other Materials:

- Challenge: Creating reliable, high-strength joints between SiC parts or be

- Challenge: Creating reliable, high-strength joints between SiC parts or be

SicSino – CAS new materials

We, CAS new materials(SicSino), have been introducing and implementing silicon carbide production technology since the 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.