Secure SiC Warehousing for Your Supply Chain Needs

Haalbare toleranties en maatnauwkeurigheid:

Secure SiC Warehousing for Your Supply Chain Needs

In today’s demanding industrial landscape, the performance and reliability of critical components are paramount. For industries ranging from semiconductors to aerospace, power electronics to high-temperature processing, silicon carbide (SiC) stands out as a material of choice. Its exceptional properties make it indispensable, but managing the supply chain for these specialized technical ceramics, including secure warehousing, is equally crucial. This blog post delves into the world of custom SiC products, their diverse applications, and the importance of a robust supply chain, ensuring your high-performance SiC components are always available and in prime condition.

1. What are Custom Silicon Carbide Products?

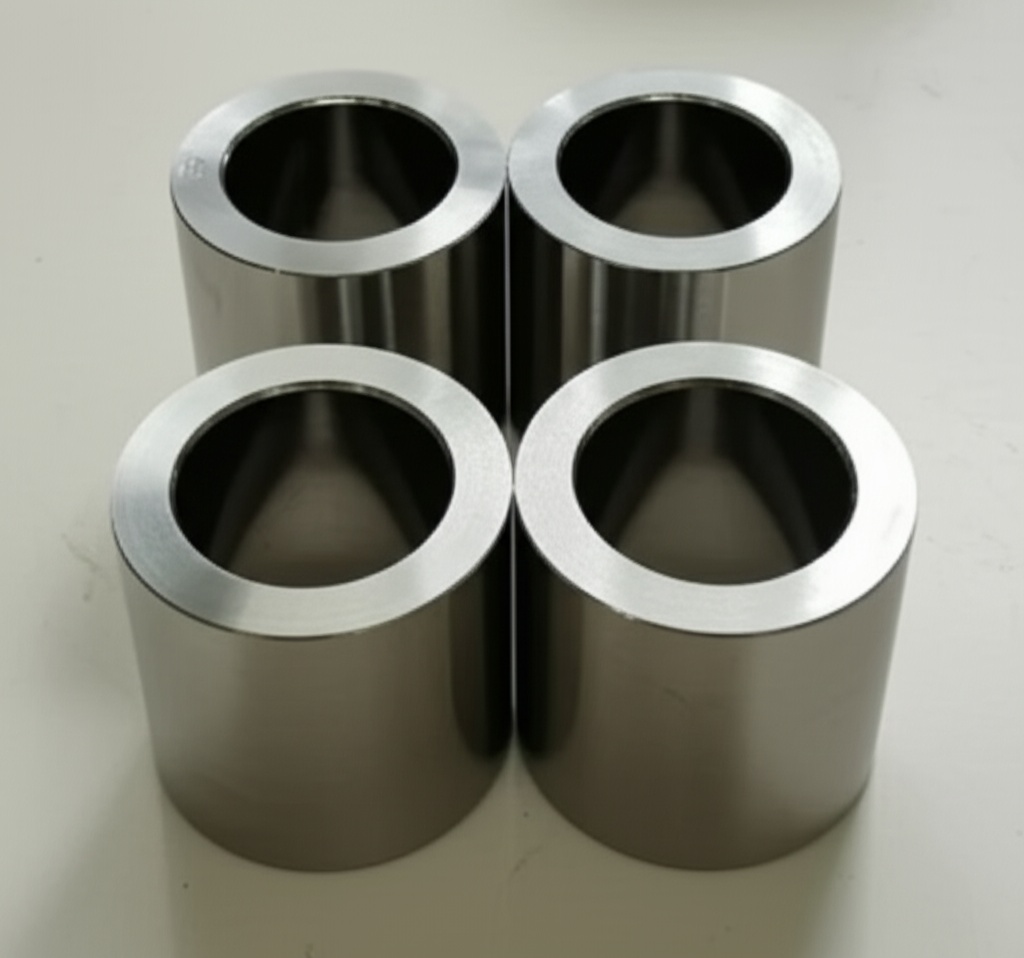

Custom silicon carbide products are engineered components made from a compound of silicon and carbon, known for their extreme hardness, high thermal conductivity, low thermal expansion, and excellent chemical resistance. Unlike standard off-the-shelf parts, custom SiC products are specifically designed and manufactured to meet the unique specifications and performance requirements of a particular application. This tailored approach allows for optimized performance in the most demanding environments, from high-temperature furnaces to advanced semiconductor manufacturing equipment. The ability to customize ensures precise fit, enhanced efficiency, and prolonged operational life for industrial machinery.

2. Main Applications of SiC Across Industries

Silicon carbide’s unique combination of properties makes it a versatile material with critical applications across a broad spectrum of industries. Its ability to withstand extreme conditions ensures reliability and efficiency where other materials fail.

| Industrie | Key Applications of SiC | Benefits of SiC |

|---|---|---|

| Productie van halfgeleiders | Wafer carriers, furnace components, susceptors, process chambers for LED manufacturing. | High thermal stability, chemical inertness, high purity. |

| Automotive | EV power inverters, on-board chargers, traction control systems, brake components. | High power density, reduced losses, improved efficiency for electric vehicles. |

| Aerospace & Defense | Mirror substrates for telescopes, hot section components, missile radomes, armor. | Lightweight, high stiffness, excellent thermal shock resistance for defense contractors. |

| Vermogenselektronica | Diodes, MOSFETs, modules for renewable energy systems (solar inverters, wind turbines), industrial power supplies. | Higher switching frequencies, reduced energy losses, compact designs. |

| Hernieuwbare energie | Inverters for solar and wind power, charging stations for EVs. | Improved efficiency and reliability in power conversion. |

| Metallurgy & High-Temp Processing | Furnace linings, kiln furniture, refractory components, heat exchangers. | Extreme temperature resistance, abrasion resistance, chemical stability for metallurgical companies. |

| Chemische verwerking | Pump components, mechanical seals, nozzles for corrosive environments. | Exceptional corrosion and erosion resistance for chemical processing companies. |

| Medical Devices | Surgical instruments, implants, specialized components requiring biocompatibility and hardness. | Biocompatibility, wear resistance, chemical inertness. |

| Olie en Gas | Downhole tools, pump seals, flow control components in abrasive and corrosive conditions. | Resistance to wear, corrosion, and high pressures. |

3. Why Choose Custom Silicon Carbide?

Opting for custom silicon carbide solutions offers distinct advantages over standard material choices, particularly for applications requiring precise performance and longevity. The benefits extend across various critical aspects:

- Optimal Performance: Custom designs ensure the SiC component is perfectly suited for its specific role, maximizing efficiency and performance, whether it’s a critical part in telecommunications equipment or a wear component in rail transportation.

- Thermal Resistance: SiC maintains its mechanical properties at extremely high temperatures, making it ideal for high-temperature processing and nuclear energy applications.

- Slijtvastheid: Its exceptional hardness provides superior resistance to abrasion and erosion, extending the lifespan of parts in demanding industrial environments.

- Chemische inertie: SiC is highly resistant to most acids, bases, and aggressive chemicals, crucial for chemical processing companies.

- Corrosiebestendigheid: Protects components from degradation in harsh, corrosive atmospheres.

- Hoge sterkte-gewichtsverhouding: Offers robust performance without adding excessive weight, vital for aerospace companies and medical device manufacturers.

- Verbeterde duurzaamheid: Leads to longer service life and reduced maintenance, resulting in lower total cost of ownership.

- Precision Engineering: Achieves tight tolerances and complex geometries, essential for intricate industrial machinery.

4. Recommended SiC Grades and Compositions

The choice of SiC grade is critical for optimizing performance in specific applications. Each type of technical ceramics offers distinct advantages:

- Reaction-Bonded Silicon Carbide (RBSC):

- Eigenschappen: Excellent thermal shock resistance, high strength, good thermal conductivity. Contains free silicon, which can limit its use in certain high-temperature or corrosive environments where the free silicon might react.

- Toepassingen: Kiln furniture, large structural components, furnace components, wear parts.

- Gesinterd siliciumcarbide (SSC):

- Eigenschappen: High purity, superior strength, excellent corrosion resistance, no free silicon. Can be more challenging to machine due to its extreme hardness.

- Toepassingen: Mechanical seals, pump components, semiconductor processing equipment, high-temperature structural parts.

- Nitride-gebonden siliciumcarbide (NBSC):

- Eigenschappen: Good strength and oxidation resistance, typically more porous than RBSC or SSC.

- Toepassingen: Refractory applications, kiln furniture, linings for abrasive material handling.

- Chemical Vapor Deposition (CVD) SiC:

- Eigenschappen: Extremely high purity, theoretical density, superior strength and stiffness, fine grain structure. Often used as a coating or for critical, thin-walled components.

- Toepassingen: Mirrors, semiconductor components, advanced optical systems.

5. Design Considerations for SiC Products

Designing SiC components requires careful consideration of the material’s inherent properties to ensure manufacturability, performance, and cost-effectiveness. Engineers must account for:

- Material Brittleness: SiC is very hard but brittle. Designs should avoid sharp corners, thin sections, and abrupt changes in cross-section that can create stress concentration points.

- Geometrie Limieten: Complex geometries can be challenging and costly to machine. Simpler, more robust designs are often preferred.

- Wanddikte: Uniform wall thicknesses are ideal to prevent warping or cracking during firing and cooling.

- Spanningspunten: Identify and mitigate potential stress concentration areas, especially for parts undergoing thermal cycling or mechanical loading.

- Joining Methods: Consider how SiC parts will be joined to other components (e.g., brazing, mechanical fasteners) and design for compatibility.

- Krimp: Account for material shrinkage during the manufacturing process, particularly in sintering.

6. Tolerance, Surface Finish & Dimensional Accuracy

Achieving precise dimensional accuracy and specific surface finishes is crucial for optimal SiC component performance. The capabilities depend on the manufacturing process and the grade of SiC:

- Haalbare toleranties:

- For sintered SiC, tolerances can be as tight as $pm 0.005$ mm for smaller features and $pm 0.05%$ for larger dimensions after grinding.

- Reaction-bonded SiC, due to its net-shape capabilities, can achieve closer to $pm 0.1%$ or $pm 0.15$ mm, typically requiring less post-machining.

- Opties voor oppervlakteafwerking:

- Zoals gebakken: Rougher finish, suitable for non-critical surfaces.

- Geslepen: Achieves a smoother finish, typical for most industrial applications.

- Gelepped/Gepolijst: Provides a very smooth, high-precision surface (e.g., for mechanical seals, optical components, semiconductor manufacturing parts). Surface roughness (Ra) can reach below 0.1 $mu$m with polishing.

- Precision Capabilities: SiC can be machined to very high precision using diamond grinding, EDM, and laser machining. This allows for intricate designs and tight fits essential in advanced systems.

7. Post-Processing Needs for SiC

Even with excellent initial fabrication, post-processing steps are often necessary to enhance the performance, durability, or specific functional attributes of custom silicon carbide products.

- Slijpen: Essential for achieving precise dimensions and improving surface finish after the initial forming and firing processes. Diamond grinding is typically used due to SiC’s extreme hardness.

- Lapping & Polishing: Critical for applications requiring exceptionally smooth surfaces, such as mechanical seals, optical components, or semiconductor wafer handling equipment, where surface friction or contamination must be minimized.

- Afdichting: For certain porous SiC grades (e.g., some RBSC formulations), sealing with glass or polymer infiltrants can improve impermeability and prevent chemical ingress.

- Coating: Applying a protective or functional coating (e.g., a CVD SiC coating for higher purity or an erosion-resistant layer) can further enhance performance in specific environments.

- Gloeien: Sometimes used to relieve internal stresses that may have developed during manufacturing, improving the material’s overall integrity.

- Schoonmaken: Thorough cleaning is often required, especially for SiC components used in high-purity environments like semiconductor or medical device manufacturing.

8. Common Challenges and How to Overcome Them

While silicon carbide offers outstanding properties, working with it presents certain challenges that need to be addressed during design and manufacturing:

- Brosheid: SiC is inherently brittle, making it susceptible to chipping or fracture under impact or tensile stress.

- Overcoming: Design components to minimize stress concentrations (e.g., generous radii, avoiding sharp corners). Utilize advanced finite element analysis (FEA) to identify and mitigate potential failure points. Ensure proper handling during manufacturing and installation.

- Complexiteit van de machinale bewerking: Its extreme hardness makes SiC difficult and costly to machine, requiring specialized diamond tools and techniques.

- Overcoming: Design for near net-shape manufacturing whenever possible to minimize post-sintering machining. Collaborate with experienced SiC manufacturers who possess advanced machining capabilities.

- Gevoeligheid voor thermische schokken: While generally good, extreme and rapid temperature changes can still induce thermal shock, particularly in larger or geometrically complex components.

- Overcoming: Incorporate design features that allow for thermal expansion, such as appropriate mounting and clearances. Select SiC grades with superior thermal shock resistance for specific applications.

- Kosten: Custom SiC components can have a higher upfront cost compared to traditional materials.

- Overcoming: Focus on the total cost of ownership, considering the extended lifespan, reduced downtime, and improved performance that SiC offers, which often leads to long-term savings. Optimize designs to reduce material usage and machining complexity.

9. How to Choose the Right SiC Supplier

Selecting a reliable supplier for custom silicon carbide products is paramount to ensuring the quality, consistency, and timely delivery of your critical components. Look for partners who demonstrate:

- Technical Capabilities: Assess their expertise in various SiC manufacturing processes (e.g., sintering, reaction bonding, hot pressing), their ability to achieve tight tolerances, and their in-house machining capabilities for technical ceramics.

- Material Options: A diverse portfolio of SiC grades (SSC, RBSC, NBSC, CVD) indicates a comprehensive understanding of different application needs.

- Quality Control & Certifications: Verify their quality management systems (e.g., ISO certifications) and adherence to industry standards, especially for industries like aerospace or medical devices.

- Experience & Track Record: Look for a supplier with a proven history of successfully delivering complex SiC components to industries similar to yours. Request case studies or client testimonials.

- Design & Engineering Support: A strong supplier will offer collaborative engineering support, helping you optimize your design for manufacturability and performance.

- Supply Chain Reliability & Warehousing: Discuss their capacity, lead times, and crucially, their ability to provide secure silicon carbide warehousing solutions to ensure consistent supply and protect your valuable components.

In the heart of China, particularly in Weifang City, lies the global hub for silicon carbide customizable parts factories. This region is home to over 40 SiC production enterprises, collectively producing more than 80% of China’s total silicon carbide output. Among these innovators, CAS nieuwe materialen (SicSino) stands out. Since 2015, we have been at the forefront, introducing and implementing advanced silicon carbide production technology, assisting local enterprises in achieving large-scale production and significant technological advancements. We’ve witnessed and contributed to the emergence and ongoing development of this dynamic industry.

As part of the CAS (Weifang) Innovation Park, which collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences (CAS), CAS nieuwe materialen (SicSino) is a national-level innovation and entrepreneurship service platform. We leverage the robust scientific, technological capabilities and talent pool of the CAS to bridge the gap between scientific achievement and commercialization. Our comprehensive service ecosystem spans the entire technology transfer and transformation process, offering more reliable quality and supply assurance within China.

We pride ourselves on possessing a domestic top-tier professional team specializing in the customized production of silicon carbide products. Our support has benefited over 215 local enterprises with our advanced technologies, including material science, process optimization, design, measurement, and evaluation. This integrated approach from materials to finished products allows us to meet diverse customization needs. We are uniquely positioned to offer you higher-quality, cost-competitive customized silicon carbide components in China. You can explore some of our successful implementations and product cases here.

Beyond providing exceptional SiC products, we are also committed to assisting you in establishing a specialized factory. If you’re looking to build a professional silicon carbide products manufacturing plant in your country, CAS nieuwe materialen (SicSino) can provide technology transfer for professional SiC production, along with a full range of services (turnkey project) including factory design, procurement of specialized equipment, installation and commissioning, and trial production. This ensures a more effective investment, reliable technology transformation, and a guaranteed input-output ratio for your silicon carbide manufacturing plant. For specific customization support, visit our dedicated page here.

10. Cost Drivers and Lead Time Considerations

Understanding the factors that influence the cost and lead time of custom silicon carbide components is crucial for effective procurement and project planning:

Kostendrijvers:

- Materiaalkwaliteit: Different SiC grades (e.g., SSC vs. RBSC) have varying raw material costs and processing complexities. Higher purity or advanced grades generally incur higher costs.

- Ontwerpcomplexiteit: Intricate geometries, tight tolerances, and thin wall sections require more specialized manufacturing processes and intensive machining, driving up costs.

- Part Size and Volume: Larger parts require more material and energy, while higher volumes can sometimes lead to economies of scale, reducing the per-unit cost.

- Vereisten voor oppervlakteafwerking: Achieving highly polished or lapped surfaces adds significant cost due to the additional machining and inspection steps involved.

- Nabewerking: Any additional treatments like coatings, specific sealing, or specialized cleaning contribute to the final price.

- Quality Control & Testing: Rigorous testing and certification for critical applications (e.g., aerospace, medical) add to the overall cost.

Overwegingen met betrekking tot de doorlooptijd:

- Beschikbaarheid van materialen: The availability of raw SiC powders or pre-forms can influence lead times, especially for specialized grades.

- Fabricageproces: The chosen production method (e.g., sintering cycle times, reaction bonding processes) directly impacts the overall lead time.

- Complexiteit van de machinale bewerking: Components requiring extensive diamond grinding or polishing will naturally have longer lead times due to the time-consuming nature of these processes.

- Design Finalization: Delays in design approval or frequent design changes can significantly extend lead times.

- Order Volume & Production Queue: Higher order volumes or a busy production schedule at the supplier can affect the lead time for new orders.

- Shipping & Logistics: International shipping and customs clearance can add considerable time, especially for global supply chains.

11. Secure SiC Warehousing for Your Supply Chain Needs

For industries relying on custom silicon carbide components, secure and efficient SiC warehousing is an often-overlooked yet critical aspect of supply chain management. Proper storage ensures the integrity, cleanliness, and readiness of these high-value technical ceramics. Our silicon carbide warehousing solutions are designed to address the unique requirements of these specialized materials:

- Climate-Controlled Environments: Maintaining stable temperature and humidity levels prevents any potential material degradation or contamination, crucial for high-purity semiconductor SiC components.

- Cleanroom Facilities: For ultra-sensitive parts, especially those used in semiconductor manufacturing or medical devices, designated cleanroom storage minimizes particulate contamination.

- Secure Inventory Management: Advanced inventory systems track each SiC component, ensuring traceability and real-time visibility for procurement managers and technical buyers.

- Protective Packaging: Components are individually packaged to prevent damage during storage and transport, particularly for brittle SiC parts.

- Strategic Stocking: We work with clients to develop strategic stocking programs, ensuring critical SiC components are readily available, minimizing lead times and mitigating supply chain disruptions for OEMs and distributors.

- Efficient Logistics & Distribution: Streamlined processes for picking, packing, and shipping ensure your custom SiC products reach their destination safely and on schedule, supporting just-in-time manufacturing or project requirements.

By offering robust silicon carbide warehousing, we provide peace of mind, knowing your investment in advanced SiC components is protected and your supply chain is resilient. This allows your operations to remain agile and responsive to market demands.

12. Frequently Asked Questions (FAQ)

- Q1: What are the primary advantages of SiC over traditional ceramic materials?

- A1: SiC offers superior hardness, extreme temperature resistance (up to $1600^circ$C or $2912^circ$F), excellent thermal conductivity, low thermal expansion, and exceptional corrosion and wear resistance. These properties make it ideal for high-performance applications where other materials would fail.

- Q2: Can silicon carbide components be repaired or refurbished?

- A2: Due to its extreme hardness and brittleness, repairing SiC components is generally challenging. Minor chips or surface imperfections can sometimes be reground or polished, but significant damage typically necessitates replacement. It’s often more cost-effective in the long run to invest in high-quality custom SiC parts initially.

- Q3: Is SiC suitable for vacuum environments?

- A3: Yes, certain grades of SiC, particularly high-purity sintered SiC and CVD SiC, are excellent for vacuum environments due to their low outgassing properties, high thermal stability, and chemical inertness. This makes them ideal for semiconductor process chambers and aerospace applications.

Conclusion

Custom silicon carbide products are indispensable for industries pushing the boundaries of performance and durability. From the precision demands of semiconductor manufacturing to the extreme conditions in aerospace and high-temperature processing, SiC offers unparalleled advantages. Choosing the right SiC supplier, one that understands the intricate design considerations, manufacturing complexities, and crucial silicon carbide warehousing needs, is vital for a robust and reliable supply chain.

Op CAS nieuwe materialen (SicSino), leveraging our deep roots in Weifang City, the global hub of SiC manufacturing, and our collaboration with the Chinese Academy of Sciences, we offer not just high-quality custom SiC components but also a partnership built on technological expertise and reliable supply. We are committed to providing you with the best customized silicon carbide components in China, ensuring your projects benefit from superior quality and competitive pricing. Whether you need specific parts or are considering building your own SiC manufacturing plant, our comprehensive support from technology transfer to turnkey solutions makes us your trusted partner in advanced technical ceramics.