SiC verwerking bij hoge temperaturen voor onverzettelijke duurzaamheid

Haalbare toleranties en maatnauwkeurigheid:

SiC verwerking bij hoge temperaturen voor onverzettelijke duurzaamheid

Introduction: The Unyielding Strength of Silicon Carbide in Extreme Environments

In the ever-evolving landscape of industrial manufacturing and high-technology sectors, the demand for materials that can withstand extreme conditions is paramount. Custom silicon carbide (SiC) products have emerged as a cornerstone material, offering unparalleled performance where others falter. Silicon carbide, a synthetic compound of silicon and carbon, is renowned for its exceptional hardness, high thermal conductivity, excellent corrosion resistance, and stability at elevated temperatures. These properties make SiC components indispensable in a multitude of high-performance industrial applications, ranging from semiconductor wafer processing to aerospace engineering and beyond. Unlike traditional materials, custom SiC parts can be engineered to meet precise specifications, offering tailored solutions that optimize efficiency, longevity, and reliability in the most demanding operational environments. This intrinsic adaptability, combined with its robust nature, makes silicon carbide a critical enabler of technological advancement across numerous industries.

The ability to tailor SiC components means that engineers and procurement managers can specify exact dimensions, purity levels, and even microstructural characteristics to achieve optimal performance. This is particularly crucial in high-temperature processing, where thermal stability, resistance to thermal shock, and minimal contamination are non-negotiable. As industries push the boundaries of temperature, pressure, and chemical exposure, the reliance on advanced ceramics like silicon carbide will only continue to grow, solidifying its status as an essential material for innovation and operational excellence.

Dominating Demanding Applications: SiC in High-Temperature Processing

Silicon carbide’s remarkable thermomechanical properties make it a go-to material for a wide array of high-temperature processing applications. Its ability to maintain structural integrity and performance under extreme thermal stress is unmatched by most metals and other ceramics. This section explores how various industries leverage SiC’s unique characteristics.

Key Industries and Applications:

- Productie van halfgeleiders: SiC is extensively used for wafer handling components, susceptors, process chamber parts (e.g., showerheads, liners, edge rings), and furnace tubes. Its high purity, thermal conductivity, and resistance to plasma erosion are critical for maintaining clean processing environments and achieving high wafer yields in processes like CVD, PVD, etching, and RTP.

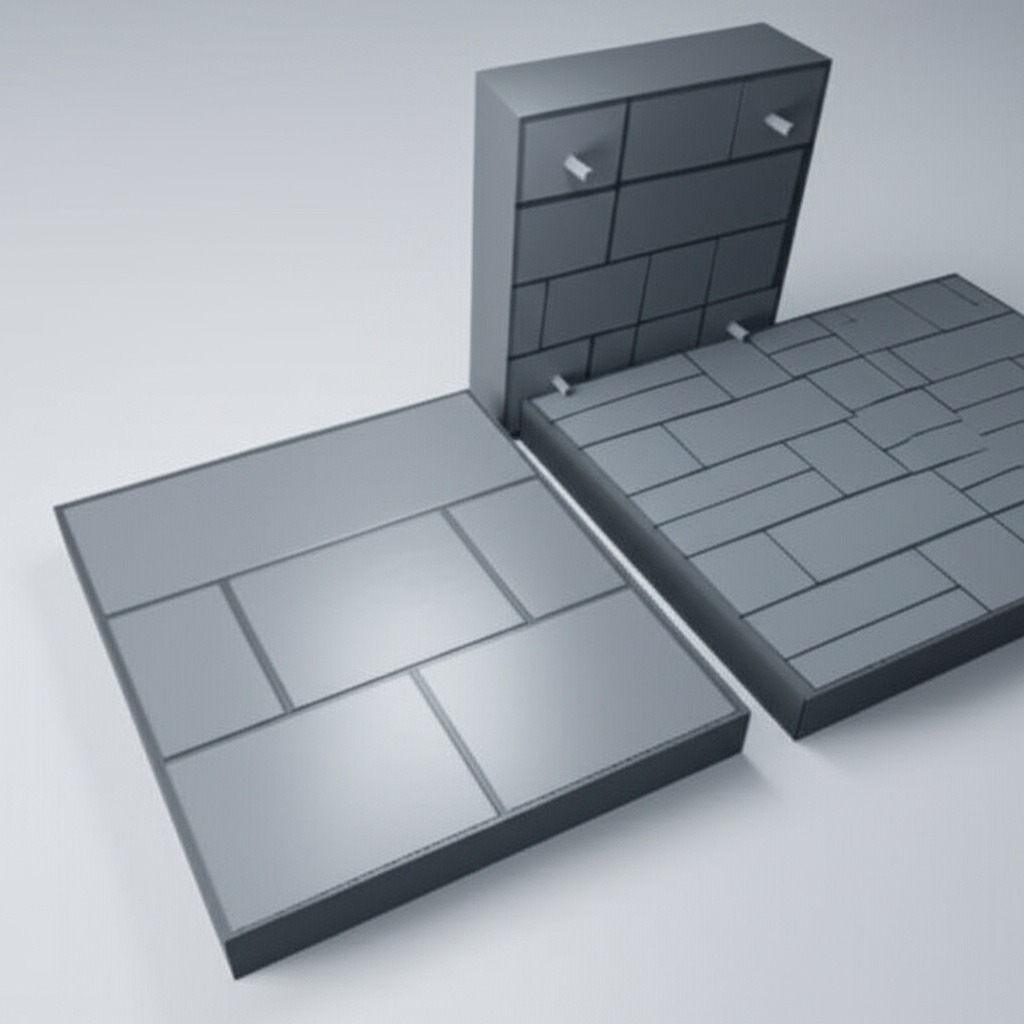

- High-Temperature Furnaces & Kilns: For industrial heat treatment, sintering, and firing processes, SiC heating elements, beams, rollers, thermocouple protection tubes, and kiln furniture (e.g., plates, setters, supports) offer extended service life and energy efficiency due to their high operating temperatures and resistance to oxidation and creep.

- Ruimtevaart en defensie: SiC composites and monolithic SiC find applications in rocket nozzles, turbine components (blades, vanes, combustors), high-performance braking systems, and armor due to their lightweight nature, high strength-to-weight ratio, and thermal shock resistance at extreme temperatures.

- Vermogenselektronica: While SiC is also a semiconductor material itself for high-power devices, SiC ceramics are used as heat sinks and substrates in power modules due to their excellent thermal conductivity and electrical insulation, enabling more compact and efficient power conversion systems.

- Metallurgy: In molten metal handling and processing, SiC components like crucibles, immersion heater tubes, and thermocouple sheaths resist corrosion and erosion from aggressive melts, ensuring process purity and longevity.

- Chemische verwerking: For handling corrosive chemicals at high temperatures, SiC is used for pump components (seals, bearings, impellers), valve parts, heat exchanger tubes, and reactor linings, offering superior chemical inertness.

- LED-productie: SiC substrates and components are used in MOCVD reactors for LED production, benefiting from their thermal stability and chemical compatibility.

- Industrial Machinery: Wear-resistant parts such as mechanical seals, nozzles, and bearings in demanding industrial equipment leverage SiC’s hardness and low friction properties.

The common thread across these diverse applications is the need for materials that do not degrade, deform, or contaminate processes when subjected to temperatures often exceeding 1000°C, sometimes reaching up to 1600°C or higher in non-oxidizing atmospheres. The reliability of custom SiC components in these environments translates directly to improved productivity, reduced downtime, and lower operational costs for manufacturers.

Why Custom Silicon Carbide is the Superior Choice for High-Temp Challenges

When standard off-the-shelf components fall short, custom silicon carbide solutions provide a distinct advantage, particularly in high-temperature, high-stress environments. The ability to tailor SiC parts to specific application requirements unlocks performance levels and component longevity that generic materials cannot achieve. This customization is key for industries seeking a competitive edge through optimized processes and enhanced product quality.

Belangrijkste voordelen van maatwerk:

- Geoptimaliseerde thermische prestaties:

- Exceptional Thermal Resistance: Custom SiC parts can be designed to withstand continuous operating temperatures exceeding 1600°C, maintaining their mechanical strength where metals would melt or deform. Different grades offer varying maximum use temperatures, allowing for selection based on specific needs.

- Hoge thermische geleidbaarheid: SiC exhibits excellent thermal conductivity (ranging from ~50 to over 200 W/mK depending on the grade and temperature), enabling rapid and uniform heat distribution or dissipation. This is crucial for applications like heat exchangers, susceptors, and kiln furniture.

- Superieure weerstand tegen thermische schokken: Custom geometries and material compositions can be optimized to enhance resistance to rapid temperature changes, preventing cracking and failure in applications with thermal cycling.

- Ongeëvenaarde slijtage- en schuurweerstand:

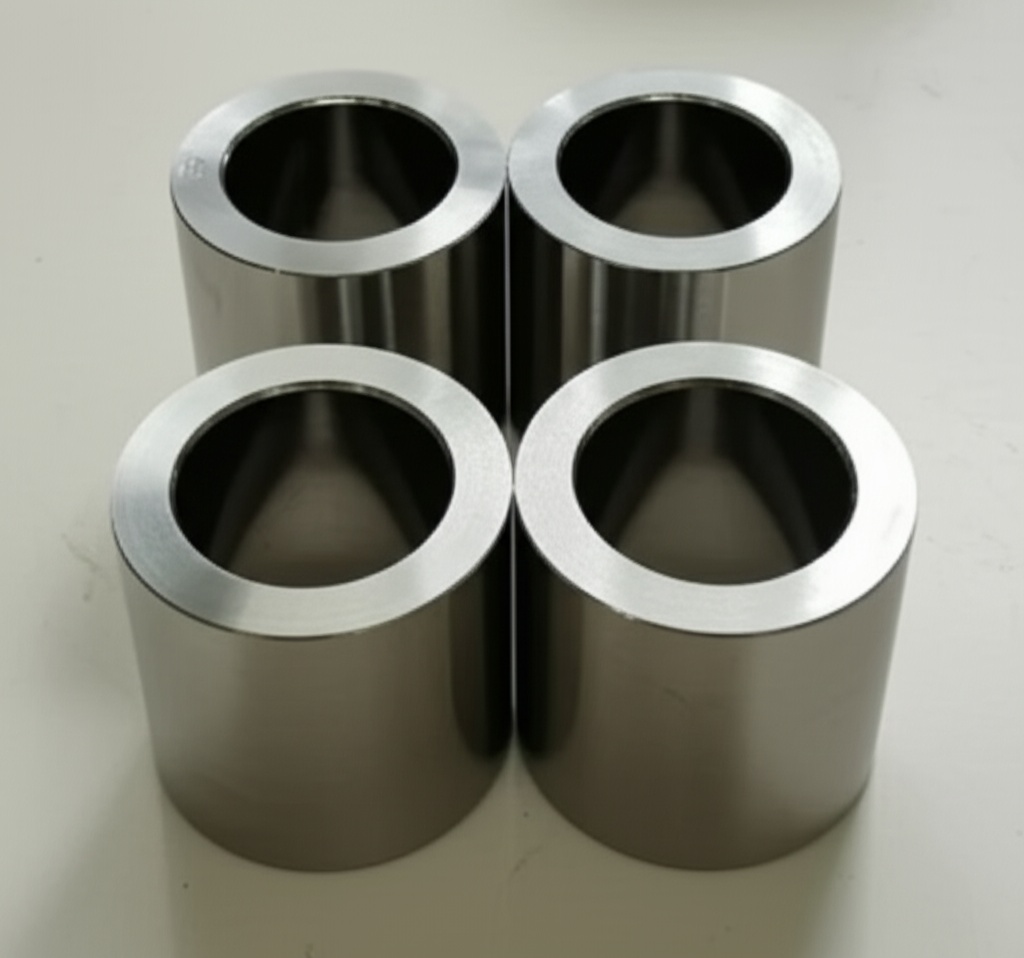

- Silicon carbide is one of the hardest commercially available materials (Mohs hardness >9), surpassed only by diamond. This makes custom SiC components like nozzles, mechanical seals, and grinding media exceptionally resistant to abrasive wear and erosion, significantly extending service life.

- Uitstekende chemische inertie en corrosiebestendigheid:

- SiC resists a wide range of acids, alkalis, and molten salts, even at elevated temperatures. Custom parts can be manufactured from high-purity SiC grades to minimize contamination and ensure compatibility with aggressive chemical environments found in chemical processing and semiconductor manufacturing.

- Ontwerpflexibiliteit voor complexe geometrieën:

- Advanced manufacturing techniques allow for the production of intricate SiC components tailored to specific functional requirements. This includes features like internal cooling channels, complex contours, and precise interfaces, optimizing performance and integration into larger systems. For highly specialized designs, partnering with an experienced supplier is crucial; CAS new materials (SicSino) provides comprehensive ondersteuning aanpassen to bring complex SiC designs to life.

- Dimensionale stabiliteit:

- SiC exhibits very low thermal expansion and high creep resistance, ensuring that components maintain their shape and tolerances even under prolonged exposure to high temperatures and mechanical loads. This is vital for precision applications in optics, metrology, and semiconductor equipment.

- Lichtgewicht sterkte:

- With a density approximately 40% that of steel, SiC offers a high strength-to-weight ratio, beneficial for aerospace components and moving parts in machinery where reduced inertia is desired.

By opting for custom silicon carbide, companies are not just purchasing a component; they are investing in a solution engineered for their specific challenge. This targeted approach ensures maximum performance, reliability, and cost-effectiveness in the long run, particularly for industrial high-temperature processing equipment.

Navigating SiC Grades: Selecting the Right Composition for Your Application

Silicon carbide is not a one-size-fits-all material. Various manufacturing processes result in different grades of SiC, each with a unique combination of properties tailored for specific applications. Understanding these distinctions is crucial for procurement managers and engineers to select the most suitable and cost-effective SiC material grade for their high-temperature processing needs.

Common Silicon Carbide Grades and Their Properties:

| SiC-kwaliteit | Productieproces | Belangrijkste kenmerken | Typische toepassingen | Max. Use Temp. (Approx.) |

|---|---|---|---|---|

| Reactiegebonden SiC (RBSiC of SiSiC) | Infiltration of molten silicon into a porous SiC + Carbon preform. | Good mechanical strength, excellent wear and oxidation resistance, high thermal conductivity, complex shape capability, relatively lower cost. Contains some free silicon (typically 8-15%). | Kiln furniture, nozzles, wear liners, rollers, beams, pump components, mechanical seals. | ~1350°C – 1380°C (limited by melting point of free silicon) |

| Sintered SiC (SSiC or SSiC-alpha) | Pressureless sintering of fine SiC powder with sintering aids (e.g., boron, carbon) at high temperatures (>2000°C). | Very high strength and hardness, excellent corrosion and wear resistance, good thermal shock resistance, high purity (no free silicon). Can be alpha or beta phase. | Mechanical seals, bearings, semiconductor processing parts, chemical pump components, heat exchanger tubes, armor. | ~1600°C – 1700°C (in oxidizing atm.), higher in inert atm. |

| Nitride-gebonden SiC (NBSiC) | SiC grains bonded by a silicon nitride (Si3N4) phase. | Good thermal shock resistance, good resistance to molten metals (especially aluminum), moderate strength. | Kiln furniture, thermocouple tubes, components for non-ferrous metal foundries, burner nozzles. | ~1400°C – 1550°C |

| Gerekristalliseerd SiC (RSiC) | High-temperature sublimation and re-deposition of SiC grains, forming a self-bonded structure. | High purity, excellent thermal shock resistance, good strength at very high temperatures, porous structure (can be CVD coated for sealing). | Kiln furniture, setters, crucibles for high-purity applications, furnace tubes. | ~1650°C (higher if coated or in inert atm.) |

| Chemically Vapor Deposited SiC (CVD-SiC) | Chemical vapor deposition process resulting in an ultra-high purity (99.999%+) polycrystalline or amorphous SiC layer. | Extremely high purity, excellent surface finish, superior corrosion and erosion resistance, fully dense. Often used as a coating or for thin, free-standing parts. | Semiconductor process chamber components (susceptors, domes, rings), optical components, protective coatings. | ~1600°C (higher depending on substrate) |

| Graphite-Loaded SiC / Silicon-Infiltrated Graphite | Often refers to composites or specific grades of RBSiC with graphite additions. | Enhanced thermal shock resistance, improved machinability for some variants, self-lubricating properties. | Bearings, seals, applications requiring good tribological performance alongside thermal stability. | Variable, depends on SiC to graphite ratio and bonding phase. Typically in the RBSiC range. |

Choosing the correct grade involves a careful analysis of the operating temperature, chemical environment, mechanical stresses, thermal cycling conditions, and cost considerations. For instance, while Sintered Silicon Carbide (SSiC) offers superior performance at very high temperatures and in corrosive environments, Reaction-Bonded Silicon Carbide (RBSiC) might be a more cost-effective solution for applications below 1350°C where complex shapes are needed. Consulting with experienced SiC product manufacturers can provide invaluable guidance in this selection process.

Critical Design Considerations for Manufacturing Custom SiC Components

Designing parts with silicon carbide requires a different approach than with metals or plastics due to its inherent ceramic nature—specifically, its hardness and brittleness. Optimizing designs for manufacturability (DfM) is crucial for achieving cost-effective, high-performance custom SiC components. Early collaboration between the design engineer and the SiC manufacturer can prevent costly redesigns and production issues.

Key Design for Manufacturability (DfM) Insights:

- Geometry Limitations & Simplification:

- While advanced forming techniques allow for complex shapes, simpler geometries are generally easier and less expensive to produce. Avoid sharp internal corners and acute angles; incorporate generous radii instead (e.g., minimum radius of 1-3mm, depending on the forming process).

- Deep holes, narrow slots, and sudden changes in cross-section can be challenging and may require specialized tooling or processes like Electrical Discharge Machining (EDM) for conductive SiC grades or post-sinter grinding.

- Wall Thickness & Aspect Ratios:

- Maintain uniform wall thickness where possible to prevent stress concentrations during sintering and thermal cycling. Recommended minimum wall thickness often starts around 2-3mm, but this is highly dependent on the overall part size and manufacturing method.

- High aspect ratios (length-to-diameter or length-to-thickness) can lead to warping or cracking during firing. Discuss limitations with your supplier.

- Managing Stress Points:

- SiC is strong in compression but weaker in tension. Designs should aim to keep SiC components under compressive loads.

- Identify potential stress concentration points (e.g., holes, notches, sharp transitions) and mitigate them with fillets, chamfers, or by distributing loads over larger areas.

- Consider the interface with other materials, especially metals with different thermal expansion coefficients, as this can induce stress.

- Verbinden en assembleren:

- Designing features for mechanical interlocking (e.g., keyways, stepped joints) can be more robust than relying solely on adhesives, especially at high temperatures.

- Brazing or specialized ceramic cements can be used for joining SiC to SiC or SiC to other materials, but the joint design must accommodate thermal expansion mismatches.

- Impact of Forming Method on Design:

- Persen (uniaxiaal, isostatisch): Best for simpler shapes or blanks that will be green-machined. Limited complexity for net-shape forming.

- Slip Casting & Extrusion: Suitable for hollow shapes, tubes, and parts with uniform cross-sections. Requires careful mold design.

- Spuitgieten (Ceramic Injection Molding – CIM): Allows for high complexity and volume production but involves higher tooling costs.

- Additieve fabricage (3D-printen): Emerging technology for SiC, offering great design freedom for prototypes and highly complex, low-volume parts. Still relatively expensive and material properties can vary.

- Tolerances for Green vs. Fired State:

- Machining SiC in its “green” (pre-sintered) state is easier and cheaper. Design with allowances for shrinkage during sintering (typically 15-20%). Final critical dimensions are often achieved by post-sinter diamond grinding.

Engaging with a knowledgeable SiC supplier early in the design phase ensures that these considerations are addressed, leading to functional, manufacturable, and cost-effective high-temperature SiC solutions. Specialized suppliers like CAS new materials (SicSino) offer extensive experience in optimizing designs for SiC production.

Achieving Precision: Tolerances, Surface Finish & Dimensional Accuracy in SiC Parts

The performance of custom silicon carbide components, especially in precision-driven industries like semiconductor and aerospace, heavily relies on achieving tight dimensional tolerances and specific surface finishes. While SiC is a hard material to shape, advanced manufacturing and finishing techniques allow for remarkable precision.

Understanding Achievable Specifications:

- As-Sintered toleranties:

- Parts directly from the sintering furnace typically have tolerances in the range of ±0.5% to ±2% of the dimension, depending on the SiC grade, part size, complexity, and manufacturing process (e.g., slip casting, isopressing).

- For less critical applications or larger components, as-sintered tolerances might be sufficient and offer a more cost-effective solution.

- Bewerktoleranties (na het sinteren):

- For high-precision requirements, SiC parts undergo diamond grinding, lapping, and polishing after sintering.

- Slijpen: Can achieve tolerances as tight as ±0.005 mm (±5 µm) to ±0.025 mm (±25 µm) for critical dimensions.

- Leppen en polijsten: Used for achieving very flat surfaces and ultra-smooth finishes, with flatness tolerances down to λ/10 (lambda/10) or better for optical applications, and dimensional control in the micron or sub-micron range for specific features.

- Oppervlakteafwerking (ruwheid):

- As-sintered: Surface roughness (Ra) can range from 1 µm to 10 µm, depending on the forming method and grain size of the SiC.

- Geslepen: Diamond grinding can achieve Ra values typically from 0.2 µm to 0.8 µm.

- Gelepped/Gepolijst: Lapping can bring Ra down to 0.02 µm – 0.1 µm. Polishing can achieve mirror finishes with Ra < 0.01 µm (10 nm), essential for optical and some semiconductor applications.

- The required surface finish often dictates the post-processing steps and significantly impacts cost.

- Maatnauwkeurigheid en stabiliteit:

- SiC’s low coefficient of thermal expansion (CTE) and high Young’s modulus contribute to its excellent dimensional stability over a wide temperature range. Once machined to precision, SiC components maintain their dimensions reliably.

- Internal stresses from manufacturing can sometimes affect long-term stability, so proper annealing or stress-relief processes might be employed by the manufacturer for critical parts.

Factors Influencing Precision:

- SiC Kwaliteit: Finer grain SiC materials generally allow for smoother finishes and tighter tolerances. The presence of secondary phases (like free silicon in RBSiC) can also influence machining characteristics.

- Part Geometry: Complex geometries, thin walls, and high aspect ratios are more challenging to machine to tight tolerances.

- Machining Technology: The type of grinding wheels, lapping compounds, polishing slurries, and machinery capabilities (e.g., CNC grinders, ultrasonic machining) play a vital role.

- Measurement and Metrology: Accurate verification of dimensions and surface finish requires sophisticated metrology equipment (CMMs, optical profilometers, interferometers).

Procurement managers and engineers should clearly define the required tolerances and surface finishes in their specifications, understanding that tighter requirements will generally increase the cost and lead time. Collaborating with a precision SiC machining expert ensures that these specifications are achievable and optimized for the application’s performance and budget.

Enhancing Performance: Essential Post-Processing for SiC Components

While the intrinsic properties of silicon carbide are impressive, many applications demand further enhancements through various post-processing treatments. These steps are designed to refine dimensions, improve surface characteristics, or add specific functionalities to the custom SiC products, ultimately boosting their performance and durability in high-temperature and other demanding environments.

Common Post-Processing Techniques:

- Diamant slijpen:

- Doel: The primary method for achieving precise dimensional accuracy and specific surface finishes on sintered SiC parts due to SiC’s extreme hardness.

- Proces: Utilizes diamond-impregnated grinding wheels on specialized machinery. Can perform surface grinding, cylindrical grinding, and complex profile grinding.

- Voordelen: Tight tolerances (microns), controlled surface roughness, shaping of complex features.

- Leppen en polijsten:

- Doel: To achieve ultra-smooth surfaces, high flatness, or specific optical properties.

- Proces: Lapping involves abrading the SiC surface with fine abrasive slurries between two flat plates (laps). Polishing uses even finer abrasives on soft pads to achieve a mirror-like finish.

- Voordelen: Extremely low surface roughness (Ra < 0.01 µm), improved wear resistance for sealing faces, optical clarity for windows or mirrors.

- Sealing / Impregnation:

- Doel: To reduce or eliminate porosity in certain grades of SiC (e.g., some RSiC or porous SSiC variants) to improve impermeability, chemical resistance, or mechanical strength.

- Proces: Involves impregnating the porous SiC structure with materials like resins, glass, or through CVD SiC coating.

- Voordelen: Reduced gas/liquid permeability, enhanced resistance to chemical attack, improved strength for some grades.

- Coatings (e.g., CVD SiC, Pyrolytic Carbon):

- Doel: To provide an ultra-high purity surface, enhance corrosion/erosion resistance, improve biocompatibility, or modify electrical properties.

- Proces: Chemical Vapor Deposition (CVD) of SiC can be applied to various SiC substrates or other materials. Pyrolytic carbon coatings are used in specific semiconductor applications.

- Voordelen: Superior surface purity, enhanced protection against aggressive environments, tailored surface functionality.

- Afschuinen/radiuscorrectie:

- Doel: To remove sharp edges, which can be points of stress concentration and chipping, especially for a brittle material like SiC.

- Proces: Typically done via grinding or specialized tooling.

- Voordelen: Improved handling safety, reduced risk of chipping during assembly or use, better mechanical integrity.

- Reiniging en uitgloeien:

- Doel: Ultra-high purity cleaning is crucial for semiconductor and medical applications. Annealing can relieve internal stresses induced during manufacturing or machining.

- Proces: Multi-stage chemical cleaning processes. Annealing involves controlled heating and cooling cycles.

- Voordelen: Removal of contaminants, improved dimensional stability, and enhanced mechanical reliability.

The selection of appropriate post-processing steps depends heavily on the specific application requirements, the grade of SiC used, and the desired final properties of the component. It’s essential to discuss these needs with your SiC component manufacturer to ensure the final product meets all performance criteria effectively and economically.

Overcoming Material Challenges: Brittleness, Machining, and Thermal Shock in SiC

Despite its many superior properties, silicon carbide, like all engineering materials, presents certain challenges that designers and users must understand and mitigate. Its inherent brittleness, difficulty in machining, and susceptibility to thermal shock under specific conditions are key considerations for ensuring successful application of custom SiC components.

Belangrijkste uitdagingen en mitigatiestrategieën:

- Broosheid en breuktaaiheid:

- Uitdaging: SiC is a brittle ceramic, meaning it has low fracture toughness compared to metals. It does not exhibit plastic deformation before fracture, leading to sudden failure if its tensile strength is exceeded or if subjected to high impact loads.

- Matigingsstrategieën:

- Design for Compression: Design components so that SiC parts are primarily under compressive, rather than tensile, stress.

- Avoid Stress Concentrators: Use generous fillets and radii instead of sharp corners. Ensure even load distribution.

- Materiaalkeuze: Some SiC grades (e.g., tougher composites or those with specific microstructures) may offer slightly improved fracture toughness.

- Proefbelasting: Voor kritieke toepassingen kunnen componenten worden getest om onderdelen met kritieke defecten uit te sluiten.

- Voorzichtige behandeling: Implement proper handling and assembly procedures to avoid impact damage or chipping.

- Complexiteit en kosten van machinale bewerking:

- Uitdaging: SiC’s extreme hardness makes it very difficult and time-consuming to machine after sintering. This typically requires diamond tooling and specialized grinding equipment, leading to higher machining costs compared to metals.

- Matigingsstrategieën:

- Vormgeving bijna op eindmaat: Utilize forming processes (e.g., slip casting, injection molding) that produce parts as close to the final desired shape as possible (“near-net shape”) to minimize post-sinter machining.

- Groene bewerking: Machine the SiC in its “green” (pre-sintered) state when it is much softer. This is less expensive but requires precise calculation of sintering shrinkage.

- Optimize Design for Machinability: Simplify geometries where possible and discuss machining feasibility with the supplier.

- Select Appropriate Grade: Some grades like RBSiC with free silicon can be slightly easier to machine than fully dense SSiC.

- Thermal Shock Susceptibility:

- Uitdaging: While SiC has good thermal sho

- Uitdaging: While SiC has good thermal sho

Zeer complexe SiC-componenten met ingewikkelde details en zeer nauwe toleranties zijn over het algemeen duurder en uitdagender om te fabriceren. Ontwerpers moeten streven naar de eenvoudigste geometrie die voldoet aan de functionele eisen. Vroegtijdig overleg met SiC-fabrikanten zoals

Wij, CAS new materials (VicSino), hebben sinds 2015 de productietechnologie voor siliciumcarbide geïntroduceerd en geïmplementeerd en de lokale bedrijven geholpen bij het realiseren van grootschalige productie en technologische vooruitgang in productprocessen. We zijn getuige geweest van de opkomst en voortdurende ontwikkeling van de lokale siliciumcarbide-industrie.