Optimizing SiC Thermal Treatment for Best Results

Share

Optimizing SiC Thermal Treatment for Best Results

In today’s demanding industrial landscape, achieving optimal thermal treatment results is paramount for efficiency, product quality, and operational longevity. Silicon Carbide (SiC) has emerged as a critical advanced ceramic material enabling significant advancements in high-temperature processes across a multitude of sectors. This post delves into the intricacies of silicon carbide thermal treatment, exploring how custom SiC components can be engineered to deliver superior performance in applications ranging from semiconductor manufacturing to aerospace engineering.

Understanding Silicon Carbide for Thermal Processes

Silicon Carbide (SiC) is a synthetic compound of silicon and carbon, renowned for its exceptional physical and chemical properties, making it an ideal material for components used in severe thermal environments. Its inherent characteristics, such as high thermal conductivity, excellent thermal shock resistance, superior strength and stiffness at elevated temperatures, and remarkable chemical inertness, position it as a material of choice for robust thermal treatment solutions. Unlike traditional metals or other ceramics, SiC maintains its structural integrity and performance under extreme heat cycling, corrosive atmospheres, and abrasive conditions. This makes custom silicon carbide fabrication essential for industries seeking reliable and long-lasting components for their thermal management systems. The ability to tailor SiC parts to specific operational requirements ensures maximum efficiency and lifespan in critical thermal applications.

Critical Advantages of SiC in Thermal Treatment

The adoption of Silicon Carbide in thermal treatment applications offers a spectrum of compelling advantages that directly translate to improved operational efficiency and product quality. These benefits stem from SiC’s unique material properties:

- Exceptional Thermal Conductivity: SiC facilitates rapid and uniform heat distribution, crucial for consistent temperature control in furnaces, kilns, and reactors. This leads to faster processing times and reduced energy consumption.

- Outstanding Thermal Shock Resistance: The ability of SiC components to withstand rapid temperature changes without cracking or degradation is vital in applications involving quick heating and cooling cycles, such as in semiconductor wafer processing.

- High Strength at Elevated Temperatures: SiC retains its mechanical strength even above 1400°C, ensuring that components like beams, rollers, and nozzles do not sag, deform, or fail under load in high-temperature environments.

- Chemical Inertness and Corrosion Resistance: SiC exhibits excellent resistance to acids, alkalis, and molten metals. This makes it suitable for harsh chemical processing environments and applications involving direct contact with corrosive substances.

- Wear and Abrasion Resistance: Its extreme hardness makes SiC highly resistant to wear and abrasion, extending the life of components like burner nozzles, thermocouple protection tubes, and setters.

- Low Density: Compared to many metals with high-temperature capabilities, SiC is relatively lightweight, which can be advantageous in designing dynamic systems or reducing the overall mass of thermal equipment.

- Customizability: SiC components can be manufactured into complex geometries, allowing for optimized designs tailored to specific thermal treatment processes. This aspect is particularly beneficial for creating high-temperature SiC components that meet unique operational demands.

These advantages make SiC a preferred material for businesses looking to enhance the performance, reliability, and cost-effectiveness of their thermal treatment operations.

Key Applications of SiC in Thermal Management

The superior properties of silicon carbide lend themselves to a wide array of thermal management and treatment applications across diverse industries. Here are some key areas where industrial SiC applications are making a significant impact:

- Semiconductor Manufacturing: SiC is extensively used for wafer processing components, including RTP chamber parts, wafer boats, pedestals, and edge rings, due to its high purity, thermal uniformity, and resistance to process gases.

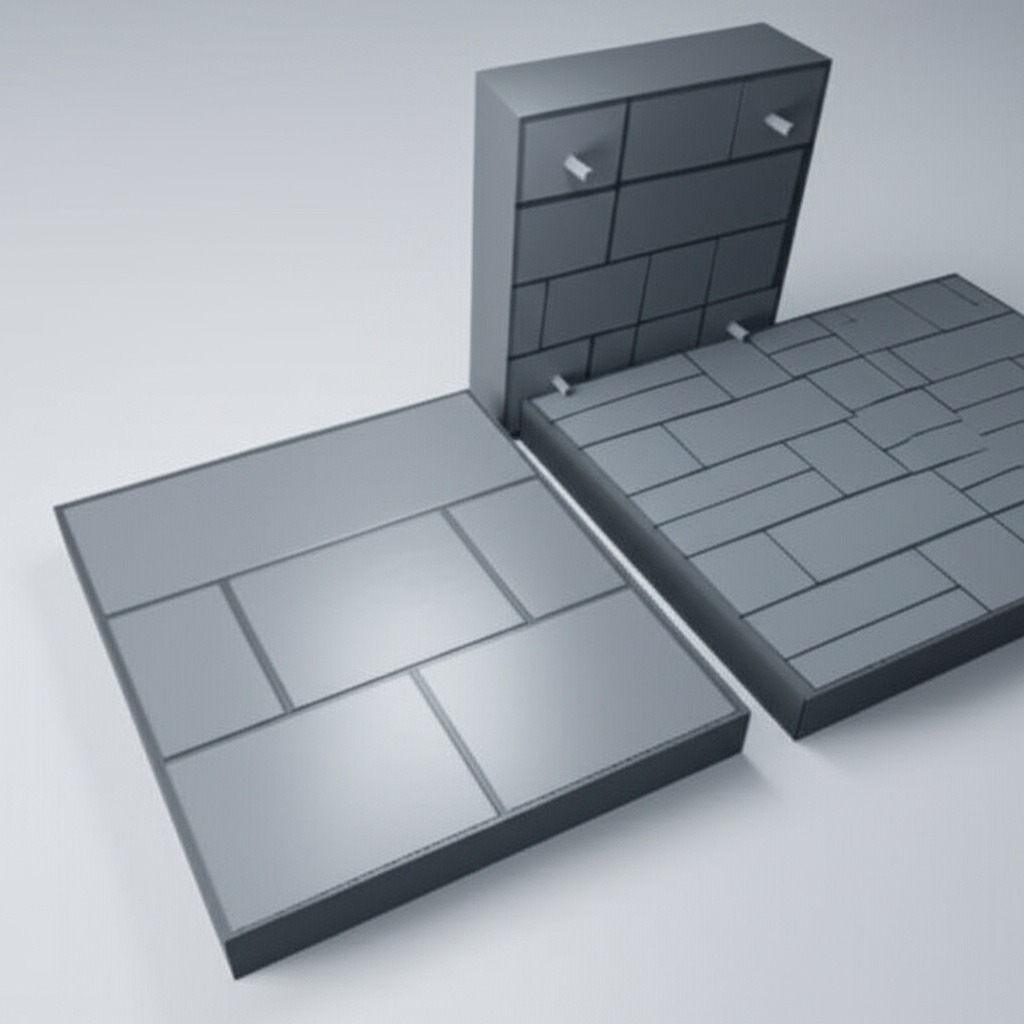

- High-Temperature Furnaces and Kilns: Components like beams, rollers, supports, setter plates, crucibles, and furnace linings benefit from SiC’s strength at high temperatures and thermal shock resistance. This is critical in ceramics firing, metal heat treatment, and glass manufacturing.

- Power Electronics: SiC is used in heat sinks and substrates for power modules due to its excellent thermal conductivity, helping to dissipate heat efficiently from high-power semiconductor devices.

- Aerospace and Defense: Components such as rocket nozzles, leading edges for hypersonic vehicles, and armor plates utilize SiC for its high-temperature stability, wear resistance, and lightweight nature. Aerospace SiC components are crucial for extreme environment performance.

- Metallurgy: Thermocouple protection tubes, immersion heater tubes, and components for handling molten metals leverage SiC’s resistance to high temperatures and corrosive environments.

- Chemical Processing: Heat exchanger tubes, pump components (seals, bearings), and reactor linings made from SiC offer extended service life in corrosive and high-temperature chemical processes.

- LED Manufacturing: Susceptors and other components in MOCVD reactors for LED production are often made from high-purity SiC for uniform heating and chemical stability.

- Renewable Energy: SiC components are found in concentrated solar power systems and are being explored for advanced nuclear reactor designs due to their thermal and radiation resistance.

- Industrial Machinery: Wear-resistant parts like mechanical seals, bearings, and nozzles in various industrial machines benefit from SiC’s hardness and durability in thermally demanding situations.

The versatility and reliability of SiC make it an enabling material for advancing thermal treatment technologies and improving process efficiencies across these critical sectors.

Recommended SiC Grades for Optimal Thermal Performance

Choosing the correct grade of silicon carbide is crucial for optimizing performance in specific thermal treatment applications. Different manufacturing processes result in SiC materials with varying characteristics. Understanding these distinctions helps in selecting the most suitable silicon carbide material properties for your needs.

| SiC Grade | Key Characteristics | Common Thermal Treatment Applications | Primary Advantages |

|---|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSiC / SiSiC) | Excellent thermal shock resistance, good wear resistance, high thermal conductivity, relatively easy to form complex shapes. Contains some free silicon. Max service temperature ~1350°C. | Kiln furniture (beams, rollers, setters), burner nozzles, heat exchangers, wear parts. | Cost-effective for large and complex shapes, good dimensional stability. |

| Sintered Silicon Carbide (SSiC) | Very high strength and hardness, excellent corrosion resistance, high thermal conductivity, high purity. Max service temperature ~1600°C (can be higher for specific grades). | Semiconductor process components, mechanical seals, bearings, advanced burner components, heat exchanger tubes in highly corrosive environments. | Superior performance in extreme conditions, highest temperature capability among common SiC grades, excellent chemical purity. |

| Nitride-Bonded Silicon Carbide (NBSC) | Good thermal shock resistance, good strength, excellent resistance to molten non-ferrous metals (e.g., aluminum). Max service temperature ~1400°C. | Crucibles for melting non-ferrous metals, thermocouple protection tubes, furnace linings in aluminum industry. | Superior resistance to wetting by molten metals, good cost-performance for specific applications. |

| Recrystallized Silicon Carbide (RSiC) | High porosity (can be good for some applications like kiln furniture), excellent thermal shock resistance, high hot strength. Max service temperature ~1650°C. | Kiln furniture (plates, posts), radiant tubes, high-temperature supports. | Lightweight, very high thermal shock resistance, good load-bearing at high temperatures. |

| CVD Silicon Carbide (CVD-SiC) | Extremely high purity (99.999%+), dense, excellent surface finish, superior chemical resistance. Max service temperature ~1700°C. | Semiconductor components (susceptors, dummy wafers, chamber parts), optical components. | Highest purity available, exceptional for contamination-sensitive applications like semiconductor processing. |

Consulting with experienced SiC material suppliers is recommended to select the optimal grade based on the specific operating conditions, including temperature, chemical environment, mechanical stress, and thermal cycling requirements of your thermal treatment process.

Design and Engineering Considerations for SiC Thermal Components

Effective design and engineering are paramount when developing custom silicon carbide components for thermal treatment applications. While SiC offers remarkable properties, its ceramic nature necessitates careful consideration during the design phase to ensure manufacturability, performance, and longevity. Key considerations include:

- Geometry and Complexity: While advanced manufacturing techniques allow for complex SiC shapes, simplifying designs where possible can reduce manufacturing costs and lead times. Avoid sharp internal corners and abrupt changes in cross-section, as these can become stress concentration points.

- Wall Thickness and Aspect Ratios: Minimum and maximum wall thicknesses are process-dependent. Thin walls can be fragile, while overly thick sections might lead to internal stresses during sintering or firing. Optimal aspect ratios should be maintained for structural integrity.

- Thermal Expansion Mismatch: When SiC components are part of an assembly with other materials (e.g., metals), differences in coefficients of thermal expansion (CTE) must be carefully managed. Design features like expansion joints or flexible mounting may be necessary to prevent stress build-up during thermal cycling.

- Load-Bearing Capacity: Understand the mechanical loads (tensile, compressive, flexural) the SiC component will experience at operating temperature. SiC is very strong in compression but weaker in tension. Design to leverage its compressive strength.

- Thermal Gradients and Shock: While SiC has excellent thermal shock resistance, extreme or uneven thermal gradients can still induce stress. Design for uniform heating and cooling where possible. Consider fillet radii to distribute stress.

- Joining and Assembly: If multiple SiC parts need to be joined, or if SiC needs to be joined to other materials, appropriate joining techniques (e.g., brazing, diffusion bonding, mechanical fastening) must be selected based on temperature and chemical compatibility.

- Manufacturability: Engage with your custom SiC manufacturing partner early in the design process. Their expertise can guide design choices compatible with specific forming (e.g., slip casting, pressing, extrusion, additive manufacturing) and firing processes.

- Gas Flow and Heat Transfer: For components like heat exchangers, nozzles, or susceptors, the design must optimize gas flow patterns and heat transfer characteristics to achieve the desired thermal performance. Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) can be valuable tools.

By addressing these design considerations proactively, engineers can develop robust and efficient SiC thermal components that fully leverage the material’s outstanding properties.

Achieving Precision: Tolerances and Surface Finishing in SiC Thermal Parts

The performance of silicon carbide components in thermal treatment applications often hinges on achieving precise dimensional tolerances and specific surface finishes. These factors influence component fit, thermal contact, fluid dynamics, and wear resistance. Modern technical ceramic solutions providers can achieve remarkable precision with SiC.

Tolerances:

- As-Sintered Tolerances: The initial tolerances after the sintering or firing process depend on the SiC grade, manufacturing method (e.g., pressing, slip casting, extrusion), and part size/complexity. Typical as-sintered tolerances might range from ±0.5% to ±2% of the dimension.

- Machined Tolerances: For applications requiring tighter control, SiC can be diamond ground, lapped, or polished. Machining can achieve much tighter tolerances, often in the range of ±0.005 mm to ±0.05 mm (±0.0002″ to ±0.002″), or even tighter for specialized applications. However, machining SiC adds cost and lead time due to its extreme hardness.

- Geometric Dimensioning and Tolerancing (GD&T): Utilizing GD&T principles is crucial for complex SiC parts to clearly define critical features, datums, and acceptable variations in form, orientation, location, and runout.

Surface Finish:

- As-Sintered Finish: The surface finish of as-sintered SiC varies with the manufacturing process and SiC grade. It might range from a few micrometers Ra (Roughness average) to tens of micrometers Ra.

- Ground Finish: Diamond grinding can significantly improve surface finish, typically achieving Ra values from 0.4 µm to 1.6 µm (16 µin to 63 µin).

- Lapped/Polished Finish: For applications demanding very smooth surfaces (e.g., seals, bearings, semiconductor components), lapping and polishing can achieve Ra values below 0.1 µm (4 µin), and even down to angstrom levels for optical-grade finishes on CVD-SiC.

- Impact on Performance:

- A smoother surface can reduce friction and wear in dynamic applications.

- In heat transfer applications, surface finish can affect radiative properties and contact resistance.

- For semiconductor processing, ultra-smooth and pure surfaces minimize particle generation and contamination.

Achieving the desired tolerances and surface finish requires specialized equipment and expertise. Discussing these requirements early with your SiC component supplier is essential to ensure the final product meets the exacting demands of your thermal treatment application. This precision is a hallmark of high-quality SiC wear parts and thermal components.

Enhancing Durability: Post-Processing for SiC Thermal Treatment Components

While silicon carbide inherently possesses excellent durability, certain post-processing treatments can further enhance its performance, lifespan, and suitability for specific thermal treatment environments. These steps are often critical for optimizing SiC furnace components and other demanding applications.

- Precision Grinding and Lapping: As discussed previously, these processes are not just for dimensional accuracy but also for improving surface quality, which can reduce stress concentrators and enhance wear resistance. Smooth surfaces are less prone to crack initiation.

- Polishing: Achieves an even finer surface finish than grinding or lapping. This is crucial for applications requiring minimal friction, high purity (reduced particle shedding), or specific optical properties.

- Edge Chamfering/Radiusing: Sharp edges on ceramic components can be prone to chipping. Adding chamfers or radii to edges improves handling robustness and reduces the risk of damage during assembly or operation.

- Cleaning and Etching: For high-purity applications, particularly in semiconductor manufacturing, SiC components undergo rigorous cleaning and sometimes etching processes to remove any surface contaminants, metallic ions, or native oxides.

- Sealing (for porous SiC grades): Some SiC grades, like certain types of RBSiC or RSiC, may have inherent porosity. For applications where gas or liquid impermeability is required, or to prevent penetration by corrosive agents, sealing treatments can be applied. This might involve impregnating the surface with glass-like materials or applying a dense SiC coating.

- Coatings:

- CVD SiC Coating: Applying a thin layer of high-purity, dense CVD SiC can significantly improve the corrosion resistance, oxidation resistance, and purity of a base SiC (e.g., SSiC or RBSiC) component. This is common for parts used in aggressive chemical environments or semiconductor processing.

- Other Ceramic Coatings: Coatings like alumina (Al2O3) or mullite might be applied for specific functionalities, such as altering electrical properties or further enhancing resistance to particular chemical attacks.

- Annealing/Stress Relieving: In some cases, particularly after extensive machining, an annealing step might be employed to relieve internal stresses induced during the shaping or grinding processes, potentially improving the component’s overall strength and thermal shock resistance.

- Joining and Assembly: If components require assembly, specialized joining techniques compatible with SiC and the operating environment (e.g., high-temperature brazing, diffusion bonding) are considered post-processing steps to create larger or more complex structures.

The selection of appropriate post-processing techniques depends heavily on the specific SiC grade, the component’s design, and the demands of its end-use thermal treatment application. Collaborating with a knowledgeable SiC supplier who offers comprehensive customizing support will ensure that components receive the optimal treatments for enhanced durability and performance.

Navigating Challenges in SiC Thermal Treatment Applications

Despite its many advantages, implementing silicon carbide in thermal treatment applications is not without its challenges. Understanding these potential hurdles and how to mitigate them is key to successful and reliable operation.

- Brittleness and Fracture Toughness: Like most ceramics, SiC is brittle, meaning it has low fracture toughness compared to metals. This makes it susceptible to catastrophic failure from impact or high localized stress.

- Mitigation: Careful design to avoid stress concentrations (e.g., using fillets, avoiding sharp corners), robust mounting and handling procedures, and selecting grades with higher fracture toughness (though this is often a trade-off with other properties). FEA analysis can help identify high-stress areas.

- Machining Complexity and Cost: Due to its extreme hardness, machining SiC (grinding, lapping) is time-consuming and expensive, requiring diamond tooling and specialized equipment.

- Mitigation: Design for near-net-shape manufacturing to minimize machining. Discuss machining requirements upfront with suppliers. Explore alternative SiC grades or manufacturing routes if ultra-high precision isn’t strictly necessary.

- Thermal Shock Management: While SiC has excellent thermal shock resistance, extreme and rapid temperature gradients can still cause failure, especially in larger or complex-shaped components.

- Mitigation: Designing for uniform heating/cooling, controlling ramp rates in thermal cycles, and selecting SiC grades specifically formulated for high thermal shock resistance (e.g., RBSiC, RSiC). Thermal modeling can predict potential issues.

- Joining SiC to Other Materials: Differences in thermal expansion coefficients (CTE) between SiC and metals or other ceramics can create significant stress at joints during thermal cycling.

- Mitigation: Use of graded transition layers, specialized brazing alloys, compliant interlayers, or mechanical designs that accommodate differential expansion.

- Oxidation at Very High Temperatures: While SiC forms a protective silica (SiO2) layer, at very high temperatures (typically above 1600-1700°C in oxidizing atmospheres), active oxidation can occur, leading to material degradation.

- Mitigation: Selecting highly pure, dense SSiC or CVD-SiC grades. Considering protective coatings or operating in controlled atmospheres if temperatures are extreme. Understanding the specific temperature limits for the chosen SiC grade in the given atmosphere.

- Cost: High-performance SiC components can be more expensive upfront compared to traditional materials like alumina or some refractory metals.

- Mitigation: Focus on the total cost of ownership (TCO). The extended lifespan, reduced downtime, and improved process efficiency of SiC often justify the initial investment. Optimize design for cost-effectiveness.

- Supplier Expertise: Finding a supplier with deep material science knowledge and advanced manufacturing capabilities for custom SiC parts is crucial.

- Mitigation: Thoroughly vet potential suppliers, looking for proven experience, technical support, and quality certifications.

Overcoming these challenges requires a combination of careful material selection, thoughtful component design, precise manufacturing, and collaboration with experienced SiC component specialists.

Choosing Your SiC Thermal Treatment Partner: Beyond the Datasheet

Selecting the right supplier for your custom silicon carbide thermal treatment components is a critical decision that extends far beyond comparing material datasheets and price quotes. A true partner will offer technical expertise, robust manufacturing capabilities, and reliable support to ensure your project’s success. Here’s what to consider when evaluating a silicon carbide OEM parts provider:

- Technical Expertise and Material Knowledge: Does the supplier have a deep understanding of various SiC grades, their properties, and their suitability for different thermal applications? Can they provide expert advice on material selection and component design?

- Customization Capabilities: Thermal treatment processes often require unique component geometries and specifications. Look for a supplier with proven experience in custom silicon carbide fabrication, from intricate designs to large-scale parts.

- Manufacturing Processes and Quality Control: Inquire about their manufacturing technologies (e.g., forming, sintering, machining). What quality management systems (e.g., ISO 9001) are in place? Can they ensure consistent quality and traceability?

- Design and Engineering Support: Can the supplier collaborate with your engineering team, offering DFM (Design for Manufacturability) insights and potentially FEA/CFD analysis to optimize component performance?

- Post-Processing Capabilities: Does the supplier offer necessary post-processing services like precision grinding, lapping, polishing, coating, or sealing in-house or through trusted partners?

- Industry Experience and Case Studies: A supplier with a track record in your industry or similar demanding applications will better understand your challenges and requirements. Ask for case studies or references.

- Location and Supply Chain Robustness: Consider the supplier’s location and its impact on logistics and communication. For instance, Weifang City in China is recognized as a major hub for silicon carbide customizable parts manufacturing, hosting over 40 SiC production enterprises that collectively account for more than 80% of China’s national SiC output.

In this prominent region, CAS new materials (SicSino) stands out. Since 2015, we have been instrumental in introducing and implementing advanced silicon carbide production technology, significantly contributing to the local industry’s large-scale production capabilities and technological process advancements. As part of the CAS (Weifang) Innovation Park, an initiative closely linked with the National Technology Transfer Center of the Chinese Academy of Sciences (CAS), SicSino benefits from the immense scientific and technological prowess of the CAS. This backing ensures a reliable foundation for innovation and quality.

CAS new materials (SicSino) offers more reliable quality and supply assurance within China. Our domestic top-tier professional team specializes in the customized production of silicon carbide products. With our support, over 144 local enterprises have benefited from our technologies, encompassing material, process, design, measurement, and evaluation technologies, along with an integrated process from materials to products. This comprehensive capability allows us to meet diverse customization needs, offering higher-quality, cost-competitive custom SiC components. Furthermore, for businesses looking to establish their own manufacturing capabilities, CAS new materials (SicSino) provides technology transfer for professional silicon carbide production, including turnkey project services for factory design, equipment procurement, installation, commissioning, and trial production, ensuring a sound investment and guaranteed input-output ratio. Learn more about our unique position and capabilities by visiting our about us page.

- Communication and Responsiveness: Effective and timely communication is vital, especially for custom projects.

- Cost vs. Value: While price is a factor, the cheapest option may not offer the best long-term value if it compromises quality, reliability, or support.

By carefully evaluating these factors, you can choose a SiC supplier that acts as a strategic partner, contributing to the optimization and success of your thermal treatment operations.

Cost Drivers and Lead Time Considerations for Custom SiC Thermal Solutions

Understanding the factors that influence the cost and lead time of custom silicon carbide thermal solutions is essential for project planning and budgeting. These elements can vary significantly based on the complexity and specifics of the required components.

Key Cost Drivers:

- SiC Material Grade: Higher purity grades (e.g., SSiC, CVD-SiC) are generally more expensive than standard industrial grades (e.g., some RBSiC types) due to more complex manufacturing processes and raw material costs.

- Component Size and Complexity: Larger parts require more raw material and may need larger processing equipment. Intricate geometries with complex features, thin walls, or tight internal radii increase tooling costs and manufacturing difficulty, thus raising prices.

- Manufacturing Process: The chosen forming method (e.g., slip casting, isopressing, extrusion, additive manufacturing) and the extent of subsequent machining significantly impact cost. Diamond grinding and polishing are particularly cost-intensive due to tool wear and processing time.

- Tolerances and Surface Finish: Tighter dimensional tolerances and finer surface finishes necessitate more precise manufacturing and machining steps, adding to the cost.

- Order Volume (Quantity): Economies of scale apply. Larger production runs typically have a lower per-unit cost due to the amortization of setup, tooling, and development expenses over more parts. Small, custom one-off orders will have a higher per-unit cost.

- Tooling Costs: For processes like pressing or injection molding, initial tooling (molds, dies) can represent a significant upfront investment. This cost is often amortized over the production volume.

- Post-Processing Requirements: Additional steps like coatings, sealing, specialized cleaning, or complex assembly add to the overall cost.

- Quality Assurance and Testing: Stringent inspection requirements, non-destructive testing (NDT), or specific certifications can increase costs but ensure reliability.

Lead Time Considerations:

- Design and Engineering Phase: Complex designs or those requiring significant engineering collaboration will extend the initial phase.

- Material Availability: Availability of specific SiC powders or raw materials can influence lead times, especially for highly specialized grades.

- Tooling Fabrication: If new tooling is required, its design and manufacture can take several weeks to months.

- Manufacturing Process Time: Forming, si

SicSino – CAS new materials

We, CAS new materials(SicSino), have been introducing and implementing silicon carbide production technology since the 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.