RBSiC: Cost-Effective & Reliable Manufacturing

Share

RBSiC: Cost-Effective & Reliable Manufacturing for Demanding Industries

In the realm of advanced materials, Reaction Bonded Silicon Carbide (RBSiC), also known as Siliconized Silicon Carbide (SiSiC), stands out as a premier choice for industries facing extreme operational conditions. This engineered ceramic composite material offers a unique blend of exceptional hardness, high-temperature resilience, superior wear resistance, and remarkable chemical inertness, making it indispensable for a wide array of high-performance industrial applications. As manufacturing processes become more demanding and operational efficiencies are paramount, the strategic selection of materials like RBSiC can significantly impact component longevity, system reliability, and overall production costs. RBSiC is not merely a material; it’s a solution that enables innovation and pushes the boundaries of what’s possible in environments where traditional materials falter. Its ability to be formed into complex net shapes or near-net shapes further enhances its appeal, reducing the need for extensive and costly post-machining processes. For engineers, procurement managers, and technical buyers, understanding the intrinsic benefits and versatile applications of RBSiC is crucial for making informed decisions that drive technological advancement and maintain a competitive edge in today’s fast-paced industrial landscape. The material’s favorable cost-performance ratio, especially for intricate designs, positions it as a go-to option for those seeking reliability without exorbitant expenditure.

Key Industrial Applications of Reaction Bonded Silicon Carbide (RBSiC)

The versatility of Reaction Bonded Silicon Carbide allows its application across a multitude of demanding sectors. Its unique property set makes it a critical material for components that must withstand harsh environments. RBSiC components are fundamental in enhancing process efficiency, reducing downtime, and improving product quality across these industries.

- Semiconductor Manufacturing: RBSiC is extensively used for wafer handling components, chucks, process chamber components, and fixtures due to its high purity, thermal stability, stiffness, and resistance to plasma and chemical corrosion. Precision and cleanliness are paramount in this sector, and RBSiC delivers.

- Automotive Industry: In automotive applications, RBSiC is found in wear-resistant components such as mechanical seals, bearings, and pump parts, particularly in systems exposed to high temperatures and abrasive fluids. Its lightweight nature combined with durability contributes to improved fuel efficiency and component longevity.

- Aerospace and Defense: The aerospace sector utilizes RBSiC for components requiring high thermal shock resistance, structural integrity at elevated temperatures, and wear resistance. Examples include rocket nozzles, turbine components, and lightweight armor, where performance under extreme conditions is non-negotiable.

- Power Electronics: For power electronics, RBSiC’s excellent thermal conductivity and electrical resistivity make it ideal for heat sinks, substrates, and insulators in high-power modules. It efficiently dissipates heat, ensuring the reliability and performance of sensitive electronic devices.

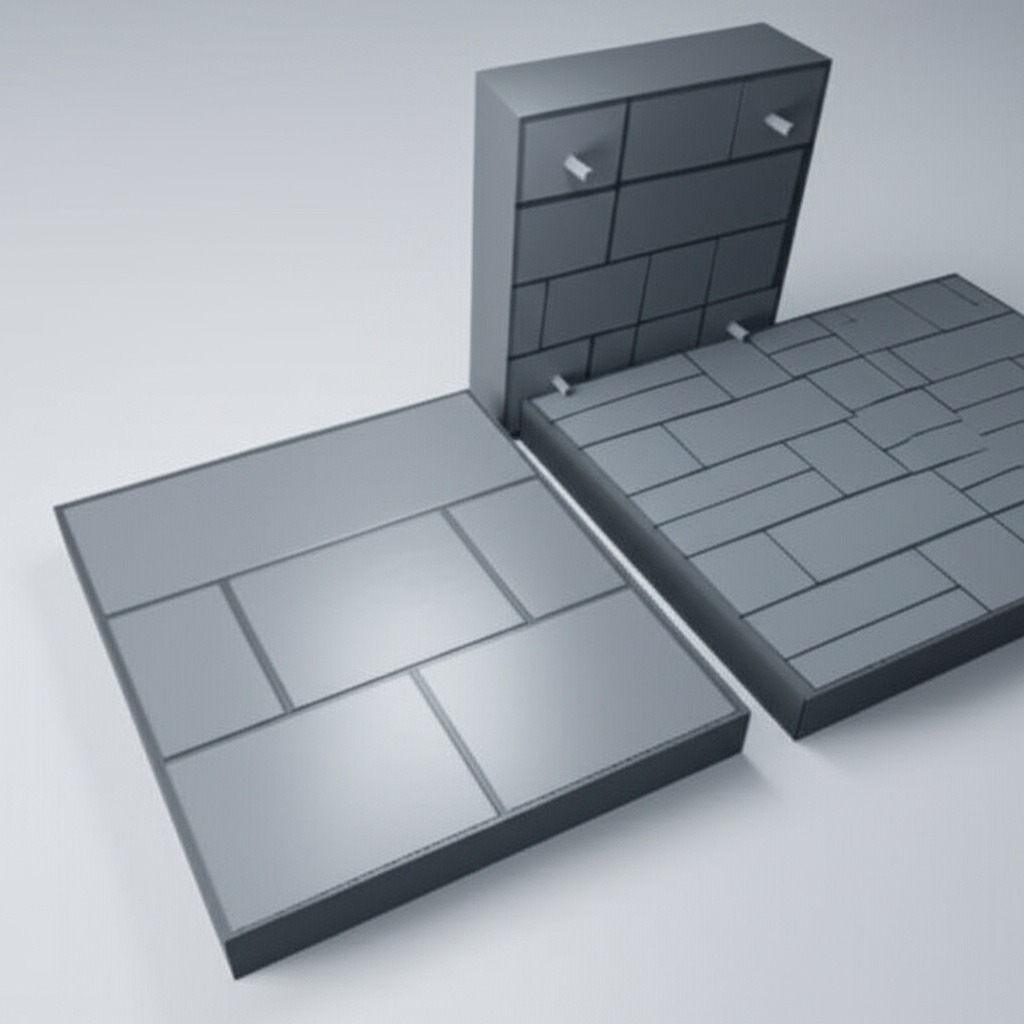

- Metallurgical Industry: In metallurgy, RBSiC serves as kiln furniture (beams, rollers, setters, plates), thermocouple protection tubes, burner nozzles, and components for molten metal handling. Its ability to withstand extreme temperatures, thermal cycling, and corrosive environments is crucial for these high-temperature processes.

- Chemical Processing: The chemical inertness and corrosion resistance of RBSiC make it suitable for pump components, valve parts, seals, and nozzles handling aggressive chemicals, acids, and alkalis, thereby extending service life and reducing maintenance.

- LED Manufacturing: Components like susceptors and handling tools made from RBSiC are used in LED production due to their thermal uniformity and stability at high processing temperatures.

- Industrial Machinery: Various industrial machines benefit from RBSiC parts like nozzles for sandblasting, cyclone liners, and wear liners in material conveying systems, where abrasion resistance is key.

- Renewable Energy: In solar and wind energy systems, RBSiC components can be found in high-temperature processing equipment for solar cells or durable parts in turbine systems.

- Oil and Gas: The demanding downhole environments and abrasive slurries in the oil and gas industry necessitate wear-resistant components, making RBSiC a candidate for valve trims, chokes, and sensor housings.

The wide adoption of RBSiC underscores its adaptability and effectiveness in addressing critical engineering challenges across these diverse and vital industries.

Why Opt for Custom Reaction Bonded Silicon Carbide (RBSiC) Components?

While standard RBSiC components serve many purposes, the true potential of this material is often unlocked through customization. Custom Reaction Bonded Silicon Carbide parts offer tailored solutions that precisely meet the unique demands of specific applications, providing a range of benefits that off-the-shelf products cannot match. Procurement professionals and engineers increasingly specify custom RBSiC to gain a competitive advantage and optimize performance.

Key advantages of custom RBSiC components include:

- Cost-Effectiveness for Complex Geometries: The reaction bonding process is particularly well-suited for producing complex, net-shape or near-net-shape parts. This minimizes the need for expensive and difficult post-sintering machining, which is a significant cost driver for other hard ceramics. Custom designs can consolidate multiple parts into a single, intricate component, reducing assembly costs and potential points of failure.

- Exceptional Wear and Abrasion Resistance: RBSiC is inherently one of the hardest commercially available materials. Customizing a component’s design to optimize its exposure to wear can significantly extend its service life, even in highly abrasive environments such as slurry pumping, pneumatic conveying, or shot blasting.

- Good Thermal Conductivity and Management: RBSiC exhibits good thermal conductivity (though typically lower than pure SiC), which is crucial for applications requiring efficient heat dissipation, like heat exchangers, kiln furniture, or power electronic substrates. Custom designs can incorporate features like cooling fins or optimized thermal paths.

- High-Temperature Stability: RBSiC maintains its mechanical strength and structural integrity at elevated temperatures (typically up to 1350-1380°C in oxidizing atmospheres), making it ideal for furnace parts, burner nozzles, and other high-temperature processing equipment. Customization ensures the component is designed to handle specific thermal loads and cycles.

- Superior Chemical Inertness and Corrosion Resistance: RBSiC is highly resistant to a wide range of acids, alkalis, and corrosive gases. Custom components can be designed to maximize this resistance in specific chemical environments found in chemical processing or metallurgical operations.

- Optimized Performance for Specific Applications: By tailoring the design, material grade (within the RBSiC family, variations in silicon content can slightly alter properties), and surface finish, custom RBSiC components deliver optimized performance that directly addresses the operational challenges of the intended application.

- Improved System Integration: Custom-designed RBSiC parts ensure perfect fit and function within larger assemblies, leading to enhanced overall system performance and reliability. This is particularly important for OEM manufacturers seeking seamless integration into their products.

Investing in custom RBSiC is an investment in longevity, efficiency, and reliability for critical industrial operations. For tailored solutions, exploring customizing support options can provide significant advantages.

Understanding RBSiC: Material Properties and the Reaction Bonding Process

Reaction Bonded Silicon Carbide (RBSiC), also frequently referred to as Siliconized Silicon Carbide (SiSiC), is a multi-phase ceramic composite. Its unique microstructure, consisting primarily of silicon carbide grains interconnected by metallic silicon, is a direct result of its distinctive manufacturing process. Understanding this process and the resultant properties is key for engineers and technical buyers specifying RBSiC for their applications.

The Reaction Bonding Process:

The manufacturing of RBSiC typically involves the following steps:

- Mixing and Forming: A mixture of silicon carbide (SiC) powder and a carbon source (e.g., graphite or a polymer binder that pyrolyzes to carbon) is prepared. This mixture is then formed into the desired shape using conventional ceramic forming techniques such as slip casting, extrusion, or pressing. This step allows for the creation of complex geometries.

- Green Machining (Optional): In some cases, the “green” (unfired) part may undergo preliminary machining to refine its shape before the high-temperature processes.

- Silicon Infiltration (Reaction Sintering): The formed part, now containing a porous structure of SiC and carbon, is heated to a high temperature (typically above the melting point of silicon, ~1414°C, often in the range of 1500-1700°C) in a vacuum or controlled atmosphere. Molten silicon is then infiltrated into the porous preform.

- Reaction and Densification: The molten silicon reacts with the carbon in the preform to form new, secondary silicon carbide. This newly formed SiC binds the original SiC grains together. Any remaining pores are typically filled with the excess molten silicon, which solidifies upon cooling. This results in a dense, relatively non-porous material with minimal firing shrinkage (typically less than 1%).

Resultant Material Properties:

The final RBSiC material typically consists of approximately 85-92% SiC and 8-15% free silicon by volume. This composition imparts a unique combination of properties:

- High Hardness and Wear Resistance: The primary SiC phase contributes to excellent hardness (Mohs hardness ~9, Knoop hardness ~25 GPa) and wear resistance.

- Good Mechanical Strength: RBSiC exhibits good flexural strength (typically 250-400 MPa at room temperature) and maintains it up to relatively high temperatures.

- Thermal Properties:

- High-Temperature Stability: Usable up to approximately 1350-1380°C. Above this, the metallic silicon phase begins to soften or melt, limiting its application temperature.

- Good Thermal Shock Resistance: Due to its relatively good thermal conductivity and moderate coefficient of thermal expansion, RBSiC offers good resistance to thermal shock compared to many other ceramics.

- Thermal Conductivity: Typically in the range of 45-85 W/mK at room temperature, which is beneficial for heat dissipation.

- Chemical Resistance: Highly resistant to acids, alkalis, and corrosive gases at moderate to high temperatures. The free silicon can be a point of attack for certain aggressive chemicals, especially strong alkalis at high temperatures.

- Electrical Properties: RBSiC is generally a semiconductor. The presence of free silicon makes it more electrically conductive than sintered SiC, which can be an advantage (e.g., for resistance heating elements) or a disadvantage depending on the application.

- Density: Typically around 3.02-3.10 g/cm³, making it relatively lightweight for a structural ceramic.

- Low Porosity: The silicon infiltration process results in a highly dense material with very low open porosity.

This combination of properties, coupled with its cost-effective manufacturing for complex shapes, makes RBSiC a versatile and widely used technical ceramic.

Design Engineering for Custom Reaction Bonded Silicon Carbide (RBSiC) Products

Effective design engineering is crucial for harnessing the full potential of custom Reaction Bonded Silicon Carbide (RBSiC) components. While RBSiC offers excellent properties and the ability to form complex shapes, certain design considerations specific to the material and its manufacturing process must be taken into account to ensure optimal performance, manufacturability, and cost-effectiveness.

Key design guidelines for RBSiC products include:

- Understanding Material Limitations:

- Brittleness: Like most ceramics, RBSiC is brittle and has low fracture toughness. Designs should aim to minimize stress concentrations. This involves using generous radii at corners and avoiding sharp edges or sudden changes in cross-section.

- Tensile vs. Compressive Strength: RBSiC, like other ceramics, is significantly stronger in compression than in tension. Designs should ideally load components in compression where possible.

- Free Silicon Content: The presence of 8-15% free silicon can affect performance in very aggressive chemical environments or at temperatures exceeding ~1380°C. Design choices should consider these limitations.

- Geometric Considerations for Manufacturability:

- Wall Thickness: Maintain reasonably uniform wall thicknesses to prevent distortion or cracking during the reaction sintering process. A minimum wall thickness is typically recommended by manufacturers (e.g., 3-5 mm, depending on overall size and geometry). Very thin sections can be challenging to produce reliably.

- Draft Angles: For pressed or cast parts, incorporate slight draft angles to facilitate easy removal from molds.

- Holes and Apertures: Design holes with appropriate aspect ratios. Deep, small-diameter holes can be difficult to form or may require post-machining. Consider the flow of molten silicon during infiltration.

- Complexity: While RBSiC excels at complex shapes, overly intricate features might increase tooling costs or processing challenges. Balance complexity with functional necessity.

- Shrinkage and Dimensional Control: RBSiC exhibits very low firing shrinkage (typically <1%) compared to other sintered ceramics. This allows for near-net-shape manufacturing with good dimensional control, reducing the need for extensive hard machining. Designers should still account for this minimal shrinkage.

- Joining and Assembly: If multiple RBSiC parts need to be joined, or if RBSiC needs to be assembled with other materials, consider appropriate joining techniques. Brazing, specialized adhesives, or mechanical fastening (with care to avoid stress concentrations) can be used. Designing interlocking features can also be beneficial.

- Surface Features: If specific surface textures or features are required, discuss these with the manufacturer. Some features can be incorporated during the initial forming stage, while others might necessitate post-processing.

- Tolerances: While near-net-shape is achievable, understand the standard tolerances for as-fired RBSiC. If tighter tolerances are needed, grinding or lapping will be required, which adds cost. Specify critical dimensions and tolerances clearly.

- Designing for Thermal Management: For high-temperature applications or those requiring heat dissipation, design features that optimize thermal performance, such as fins, uniform sections for heat distribution, or specific orientations to manage thermal gradients.

- Prototyping and Iteration: For complex or critical components, consider a prototyping phase. This allows for design validation and refinement before committing to large-scale production.

Collaborating closely with an experienced RBSiC manufacturer during the design phase is highly recommended. Their expertise can provide invaluable insights into design for manufacturability (DFM), material selection nuances, and potential cost-saving opportunities. Early engagement helps ensure that the final component is not only functional but also economically viable to produce.

Precision Matters: RBSiC Tolerances, Surface Finish, and Dimensional Accuracy

For many industrial applications, particularly in sectors like semiconductor manufacturing, aerospace, and precision machinery, the dimensional accuracy, achievable tolerances, and surface finish of components are critical performance factors. Reaction Bonded Silicon Carbide (RBSiC) offers distinct advantages in achieving near-net shapes, but understanding the specifics of its precision capabilities is essential for technical buyers and engineers.

Tolerances with RBSiC:

One of the significant benefits of the RBSiC manufacturing process is its inherently low firing shrinkage, typically less than 1%. This contrasts sharply with many sintered ceramics that can experience shrinkage of 15-20%, making dimensional control more challenging and often requiring significant post-firing machining.

- As-Fired Tolerances: For as-fired RBSiC components (i.e., parts that have not undergone subsequent machining), typical dimensional tolerances are often in the range of ±0.5% to ±1.5% of the dimension, or a minimum absolute tolerance (e.g., ±0.5 mm), depending on the size and complexity of the part. Larger parts may have proportionally larger absolute tolerances.

- Machined Tolerances: When tighter tolerances are required, RBSiC components can be precision machined using diamond grinding, lapping, or polishing. Through these processes, much tighter tolerances can be achieved, often down to ±0.01 mm (10 microns) or even better for critical dimensions on smaller parts. However, machining hard ceramics like RBSiC is a slow and costly process, so it should only be specified where absolutely necessary.

Surface Finish Options for RBSiC:

The surface finish of an RBSiC component can significantly impact its performance, especially in applications involving friction, wear, sealing, or fluid dynamics.

- As-Fired Surface: The as-fired surface of RBSiC is relatively smooth but will have a texture reflecting the mold surface and the nature of the reaction bonding process. Typical Ra (average roughness) values might be in the range of 1 to 5 µm.

- Ground Surface: Grinding with diamond wheels can achieve a much smoother surface finish, typically with Ra values ranging from 0.4 to 0.8 µm. This is often sufficient for many mechanical applications.

- Lapped and Polished Surfaces: For applications requiring exceptionally smooth and flat surfaces (e.g., seals, bearings, semiconductor wafer chucks), lapping and polishing processes can be employed. These can achieve Ra values of less than 0.1 µm, and in some cases, optical-quality finishes.

Dimensional Accuracy and Stability:

RBSiC exhibits excellent dimensional stability over time and under varying thermal conditions (within its operational temperature limits). Its low coefficient of thermal expansion (CTE), combined with high stiffness, means that components maintain their shape and dimensions reliably during service. This is critical for precision equipment where even minor dimensional changes can affect performance.

Achieving the desired precision requires close collaboration between the customer and the RBSiC manufacturer. Key considerations include:

- Clearly defining critical dimensions and their required tolerances on engineering drawings.

- Specifying the required surface finish for functional surfaces.

- Discussing inspection methods and metrology capabilities.

While the near-net-shape capability of RBSiC reduces the need for extensive machining, understanding the trade-offs between as-fired precision and the costs associated with secondary finishing operations is crucial for optimizing both performance and budget.

Enhancing Performance: Post-Processing Options for RBSiC Components

While Reaction Bonded Silicon Carbide (RBSiC) components often exhibit excellent properties directly after the reaction sintering process (as-fired condition), certain applications may demand enhanced dimensional accuracy, specific surface characteristics, or improved functionalities. Post-processing operations can tailor RBSiC parts to meet these stringent requirements, further broadening their applicability in demanding industrial environments. These secondary steps, while potentially adding to the cost and lead time, are crucial for optimizing performance in critical applications.

Common post-processing techniques for RBSiC include:

- Diamond Grinding:

- Purpose: To achieve tighter dimensional tolerances, improve surface flatness or cylindricity, and remove any minor distortions from the firing process. It is the most common machining method for hard ceramics like RBSiC.

- Process: Utilizes diamond abrasive wheels due to RBSiC’s extreme hardness. Various grinding techniques like surface grinding, cylindrical grinding, and centerless grinding can be applied.

- Outcome: Significantly improved dimensional accuracy (tolerances often in the range of ±0.01 to ±0.05 mm) and smoother surface finishes (typically Ra 0.4-0.8 µm).

- Lapping:

- Purpose: To produce exceptionally flat surfaces and achieve very fine surface finishes, often required for sealing faces, bearings, or substrates.

- Process: Involves abrading the RBSiC surface against a flat plate (lap) using a slurry containing fine abrasive particles (often diamond).

- Outcome: Achieves high degrees of flatness (e.g., within a few light bands) and very smooth surfaces (Ra < 0.2 µm).

- Polishing:

- Purpose: To achieve an even finer surface finish than lapping, often to a mirror-like or optical quality. This is critical for applications like semiconductor wafer chucks or optical components (though RBSiC is opaque).

- Process: Similar to lapping but uses progressively finer abrasive particles and specialized polishing pads.

- Outcome: Extremely smooth surfaces (Ra < 0.05 µm) with minimal subsurface damage.

- Cleaning and Etching:

- Purpose: To remove surface contaminants, residues from machining, or to slightly modify the surface chemistry for specific applications (e.g., improving adhesion for coatings).

- Process: Can involve ultrasonic cleaning in specialized solvents, or controlled chemical etching.

- Sealing or Impregnation (Less Common for RBSiC):

- Purpose: While RBSiC is inherently dense due to the silicon infiltration filling most pores, some specialized applications might seek to ensure absolute impermeability or modify surface properties.

- Process: This could involve impregnating with resins or glasses, though this is more common for porous ceramics. For RBSiC, surface treatments are more typical.

- Coatings (Surface Treatments):

- Purpose: To impart additional functionalities not inherent to RBSiC, such as enhanced corrosion resistance against specific aggressive media, improved lubricity, or different electrical properties on the surface.

- Process: Techniques like Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), or specialized paints/enamels can be applied. The choice of coating depends heavily on the application requirements and compatibility with RBSiC. For instance, a CVD diamond coating could further enhance wear resistance.

- Laser Machining:

- Purpose: For creating fine features, drilling small holes, or scribing, where mechanical machining might be challenging or induce stress.

- Process: Uses high-powered lasers to ablate material. It offers precision but can have limitations regarding material removal rates and potential thermal effects.

The decision to employ post-processing techniques should be based on a careful cost-benefit analysis. Engineers and procurement managers must clearly define the required specifications for their RBSiC components to determine which, if any, post-processing steps are necessary. Consulting with an experienced RBSiC supplier is vital to understand the capabilities, costs, and implications of these finishing operations on the final product’s performance and durability.

Navigating Challenges with RBSiC: Solutions and Mitigation Strategies

Reaction Bonded Silicon Carbide (RBSiC) is a highly effective material for a multitude of demanding applications, yet, like any engineering material, it presents certain challenges in its manufacturing and application. Understanding these potential issues and implementing appropriate mitigation strategies is key to successfully leveraging RBSiC’s benefits. Technical buyers and engineers should be aware of these considerations to ensure optimal component design and long-term reliability.

Common challenges and their solutions include:

- Presence of Free Silicon:

- Challenge: RBSiC contains 8-15% metallic silicon. While this contributes to its near-net-shape manufacturability, free silicon has a lower melting point (~1414°C) than SiC and can be preferentially attacked by certain aggressive chemicals (e.g., strong alkalis, hydrofluoric acid) or molten metals. This limits the maximum service temperature to around 1350-1380°C.

- Mitigation:

- Carefully assess the chemical and thermal environment of the application. Ensure the operating temperature remains below the softening point of silicon.

- For extreme chemical environments or higher temperatures, consider alternative SiC grades like Sintered Silicon Carbide (SSiC), although SSiC is typically more expensive and harder to form into complex shapes.

- In some cases, protective coatings can shield the free silicon.

- Brittleness and Fracture Toughness:

- Challenge: Like most advanced ceramics, RBSiC is brittle, meaning it has low tolerance for impact or high tensile stresses and can fracture without significant plastic deformation.

- Mitigation:

- Employ ceramic-friendly design principles: use generous radii, avoid sharp corners and stress concentrators, and design for compressive loading where possible.

- Ensure proper handling and installation procedures to prevent mechanical shock.

- Consider system design that protects the ceramic component from direct impact.

- Perform stress analysis (e.g., FEA) on critical components to identify high-stress regions and optimize the design.

- Machining Complexity and Cost:

- Challenge: Due to its extreme hardness, machining RBSiC (when required for tight tolerances or complex features not achievable in the green state) must be done with diamond tooling. This process is slow, specialized, and can be expensive.

- Mitigation:

- Maximize near-net-shape forming capabilities during the initial manufacturing stage to minimize the need for post-sintering machining.

- Specify machining only for critical dimensions and surfaces where absolutely necessary.

- Discuss achievable as-fired tolerances with the supplier to see if they meet requirements without machining.

- Thermal Shock Resistance:

- Challenge: While RBSiC has good thermal shock resistance compared to many ceramics due to its thermal conductivity and strength, rapid temperature changes can still induce stress and potential cracking, especially in larger or complex-shaped components.

- Mitigation:

- Design for uniform heating and cooling where possible. Avoid creating large thermal gradients across the component.

- Consider the component’s geometry; thinner sections and simpler shapes generally have better thermal shock resistance.

- If extreme thermal cycling is expected, ensure this is communicated to the supplier, as specific design or minor compositional adjustments (within RBSiC family) might offer marginal improvements. Compare with other SiC types if this is a primary failure mode.

- Joining to Other Materials:

- Challenge: Differences in Coefficient of Thermal Expansion (CTE) can make it challenging to join RBSiC to metals or other ceramics, as temperature changes ca

- Challenge: Differences in Coefficient of Thermal Expansion (CTE) can make it challenging to join RBSiC to metals or other ceramics, as temperature changes ca

SicSino – CAS new materials

We, CAS new materials(SicSino), have been introducing and implementing silicon carbide production technology since the 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.