Tight SiC Tolerances for Precision Component Parts

Поделиться

Tight SiC Tolerances for Precision Component Parts

In today’s demanding industrial landscape, where extreme conditions and unparalleled precision are the norm, the materials used in critical components must perform flawlessly. Among advanced ceramics, карбид кремния (SiC) stands out as a material of choice, offering an exceptional combination of properties. For engineers, procurement managers, and technical buyers across industries like semiconductors, aerospace, power electronics, and high-temperature processing, understanding the intricacies of SiC tolerances is paramount to achieving optimal performance and longevity in their precision component parts.

The Unrivaled Edge of Custom Silicon Carbide Products

Custom silicon carbide products are not merely components; they are engineered solutions designed to meet the most stringent operational requirements. Unlike off-the-shelf options, custom SiC parts are tailored to specific applications, leveraging the material’s inherent strengths: superior hardness, exceptional thermal conductivity, low thermal expansion, remarkable chemical inertness, and excellent wear resistance. This customization ensures that each component integrates seamlessly into complex systems, providing enhanced efficiency and reliability in critical industrial applications.

Main Applications of Precision SiC Components Across Industries

The versatility of silicon carbide allows it to thrive in environments where other materials fail. Its unique properties make it indispensable across a multitude of high-tech and heavy industries:

- Производство полупроводников: SiC is vital for wafer processing equipment, electrostatic chucks, and furnace components due to its thermal stability and plasma resistance. Tight SiC tolerances ensure precise positioning and thermal uniformity.

- Автомобильная промышленность: Power electronics in electric vehicles (EVs) and hybrid vehicles benefit immensely from SiC’s ability to handle high voltages and temperatures, leading to more efficient inverters and chargers.

- Аэрокосмическая и оборонная промышленность: Used in lightweight, high-temperature structural components, rocket nozzles, and missile radomes, where thermal shock resistance and strength-to-weight ratio are critical.

- Силовая электроника: SiC devices enable higher power density, faster switching speeds, and reduced energy losses in power modules for renewable energy systems, industrial motor drives, and uninterruptible power supplies (UPS).

- 21870: Возобновляемая энергия: Essential for efficient power conversion in solar inverters and wind turbine generators, optimizing energy harvesting and distribution.

- Metallurgy and High-Temperature Furnaces: SiC furnace components, kiln furniture, and heat exchangers offer superior thermal shock resistance and mechanical strength at elevated temperatures.

- Химическая обработка: Its excellent chemical inertness makes SiC ideal for pump seals, bearings, and valve components in corrosive environments.

- 22379: Производство светодиодов: SiC wafers serve as substrates for GaN-based LEDs, enabling high-brightness and efficient lighting solutions.

- Промышленное оборудование: SiC wear parts such as mechanical seals, bearings, and nozzles significantly extend the lifespan of equipment operating in abrasive or corrosive conditions.

- Телекоммуникации: Used in high-frequency and high-power communication systems where thermal management is crucial.

- Нефть и газ: SiC components are employed in downhole tools and pumping equipment due to their extreme wear and corrosion resistance.

- Медицинские приборы: Precision SiC parts can be found in advanced medical equipment requiring high purity and precise movements.

- Rail Transportation: Power electronics and braking systems leverage SiC for enhanced efficiency and reliability.

- Атомная энергия: SiC is being explored for next-generation nuclear reactors due to its high-temperature stability and radiation resistance.

Advantages of Custom Silicon Carbide for Precision Component Parts

Opting for custom SiC parts offers a strategic advantage, especially when tight tolerances are a primary requirement. Here’s why:

- Unmatched Thermal Resistance: SiC maintains its mechanical properties and structural integrity at temperatures exceeding 1,500°C, making it suitable for extreme thermal environments.

- Исключительная износостойкость: Its inherent hardness, second only to diamond, provides unparalleled resistance to abrasion and erosion, significantly extending the lifespan of components in high-friction applications.

- Превосходная химическая инертность: SiC resists attack from most acids, bases, and molten salts, ensuring reliability in highly corrosive chemical processing environments.

- Высокая прочность и жесткость: Despite its light weight, SiC exhibits excellent strength and stiffness, allowing for the design of robust yet thin-walled components.

- Низкое тепловое расширение: SiC’s low coefficient of thermal expansion minimizes thermal stresses and deformation, crucial for maintaining dimensional stability and tight tolerances across varying temperatures.

- Высокая теплопроводность: This property facilitates efficient heat dissipation, critical for high-power electronic devices and thermal management systems.

- Диэлектрическая прочность: Essential for insulation in high-voltage applications, SiC provides reliable electrical isolation.

Recommended SiC Grades and Compositions for Diverse Applications

The performance of custom silicon carbide products is also dependent on the specific grade and composition chosen. Each type offers a unique balance of properties:

| SiC Grade/Type | Composition/Bonding | Основные свойства | Типовые применения |

|---|---|---|---|

| Реакционно-связанный SiC (RBSiC) | SiC infiltrated with free silicon (Si) | High strength, excellent wear resistance, good thermal conductivity, lower porosity. Relatively easy to machine in green state. | Mechanical seals, pump components, heat exchangers, kiln furniture, armor. |

| Спеченный SiC (SSiC) | High purity SiC densified at high temperatures (typically with sintering aids like B and C). | Extremely high strength, hardness, wear resistance, excellent chemical resistance, no free silicon. | Bearing components, nozzles, semiconductor processing equipment, ballistic armor. |

| Нитрид-связанный SiC (NBSiC) | SiC grains bonded with silicon nitride (Si₃N₄). | Good thermal shock resistance, moderate strength, high refractoriness, good oxidation resistance. | Refractory linings, kiln furniture, molten metal contact applications. |

| CVD SiC (Chemical Vapor Deposition SiC) | High purity SiC deposited on a substrate. | Extremely high purity, near-theoretical density, isotropic properties, excellent surface finish. | Semiconductor wafer carriers, optical components, mirror substrates, high-purity furnace parts. |

Design Considerations for Achieving Tight SiC Tolerances

Designing with silicon carbide for precision component parts requires careful consideration of its unique properties and manufacturing limitations. To achieve the tightest SiC tolerances, engineers must focus on:

- Выбор материала: Choose the SiC grade that best matches the application’s thermal, mechanical, and chemical requirements.

- Пределы геометрии: Avoid overly complex geometries, sharp internal corners, or sudden changes in cross-section, which can induce stress concentrations during manufacturing and operation.

- Толщина стенок: Aim for uniform wall thicknesses whenever possible to minimize distortion during firing and ensure consistent material properties.

- Точки напряжения: Identify potential stress points and design features that distribute stress evenly, such as generous radii and chamfers instead of sharp edges.

- Обрабатываемость: SiC is extremely hard, making post-sintering machining challenging and expensive. Design parts that minimize the need for extensive post-processing, or consider near-net-shape forming.

Achieving Precision: Tolerance, Surface Finish & Dimensional Accuracy in SiC

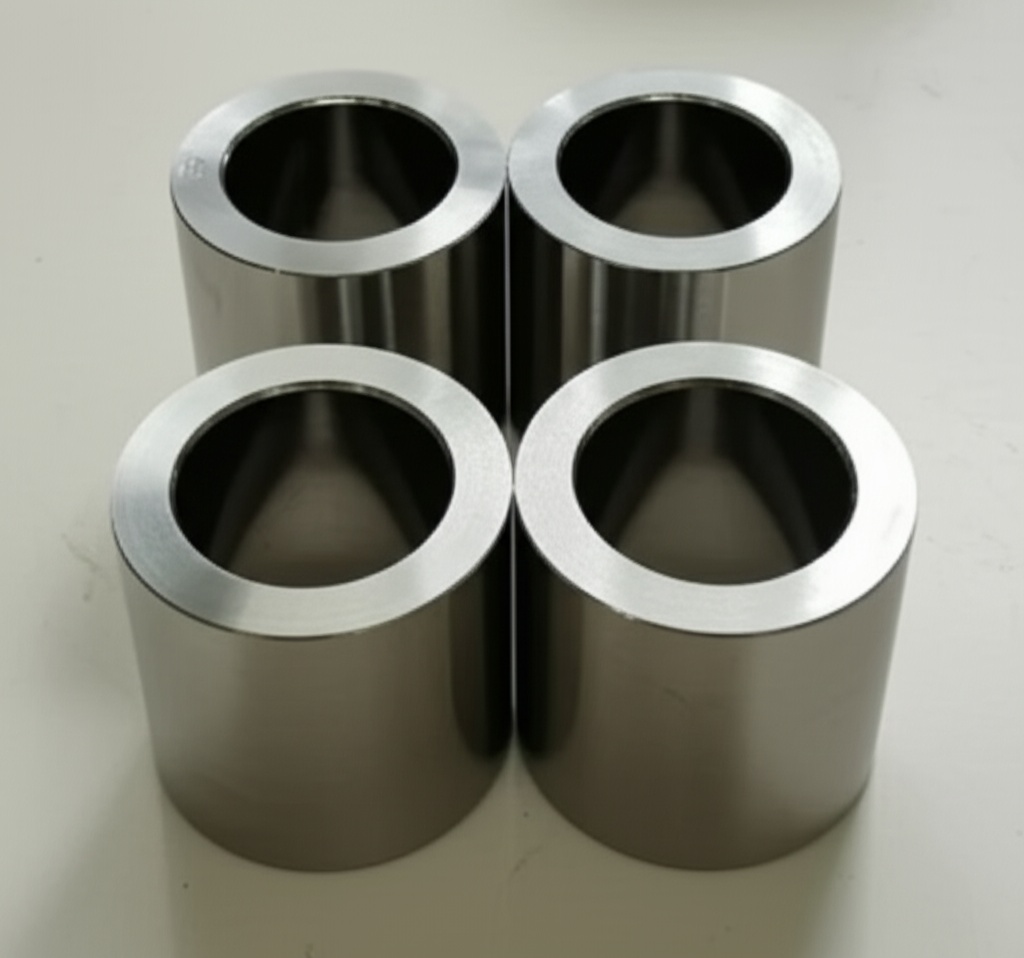

Achieving tight SiC tolerances is a hallmark of high-quality silicon carbide manufacturing. Due to its extreme hardness, SiC is typically formed to near-net-shape before firing, and then precision ground or lapped to final dimensions. Achievable tolerances vary depending on the specific SiC grade, part size, complexity, and the finishing processes employed. Generally, custom silicon carbide product manufacturers can achieve:

- Допуски на размеры: For standard features, $pm 0.05 text{ mm}$ to $pm 0.1 text{ mm}$ is common. With advanced grinding and lapping, tolerances as tight as $pm 0.005 text{ mm}$ to $pm 0.015 text{ mm}$ can be achieved on critical dimensions for precision component parts.

- Плоскостность и параллельность: Can be maintained to a few micrometers for highly critical surfaces, essential for semiconductor applications.

- Отделка поверхности: As-fired surfaces are typically in the $text{Ra } 1.6 text{ text{ to } } 3.2 text{ text{ µm}}$ range. Precision lapping and polishing can achieve mirror-like finishes of $text{Ra } 0.1 text{ text{ µm}}$ or even smoother for critical sealing or optical applications.

Post-Processing Needs to Enhance SiC Performance

While SiC offers exceptional inherent properties, certain post-processing steps can further enhance its performance, durability, and functional attributes:

- Прецизионное шлифование: Essential for achieving tight dimensional tolerances, parallelism, and flatness on critical surfaces. Diamond tooling is exclusively used for this process.

- Притирка и полировка: Used to achieve exceptionally smooth surface finishes, crucial for sealing applications, optical components, or parts requiring low friction.

- Honing: For internal diameters or complex bores, honing can improve surface finish and dimensional accuracy.

- Герметизация/пропитка: For certain porous grades (e.g., some forms of RBSiC), impregnation with polymers or metals can improve impermeability for specific applications.

- Покрытие: Application of specialized coatings (e.g., CVD SiC, pyrolytic carbon) can enhance surface purity, electrical properties, or provide additional wear protection.

Common Challenges and How to Overcome Them in SiC Manufacturing

Working with silicon carbide presents unique challenges that experienced manufacturers are adept at overcoming:

- Хрупкость: Like most ceramics, SiC is brittle and susceptible to fracture under tensile stress or impact. Designs should minimize stress concentrations and incorporate features that distribute loads effectively. Proper handling during manufacturing and installation is crucial.

- Сложность обработки: The extreme hardness of SiC makes conventional machining impossible after sintering. This necessitates near-net-shape forming or expensive diamond grinding, which drives up costs. Close collaboration with the manufacturer during the design phase is key to optimizing manufacturability.

- Чувствительность к тепловому удару: While SiC has good thermal shock resistance, rapid and extreme temperature changes can still induce stress. Careful design of thermal gradients and pre-heating/cooling cycles can mitigate this risk.

- Высокие температуры спекания: SiC requires extremely high temperatures for sintering, demanding specialized equipment and precise atmospheric control.

- Стоимость: Due to raw material purity requirements, complex manufacturing processes, and specialized machining, SiC components can be more expensive than conventional materials. However, their extended lifespan and superior performance often result in a lower total cost of ownership.

How to Choose the Right SiC Supplier for Your Needs

Selecting a reputable and experienced silicon carbide supplier is paramount to the success of your project, especially when precision and tight SiC tolerances are critical. Look for a vendor with:

- Extensive Technical Capabilities: They should possess deep knowledge of SiC material science, design for manufacturability, and advanced machining techniques.

- Broad Material Options: The supplier should offer a range of SiC grades (RBSiC, SSiC, CVD SiC, etc.) to match your specific application needs.

- Сертификаты качества: Adherence to international quality standards (e.g., ISO 9001) demonstrates a commitment to consistent product quality and reliability.

- Advanced Manufacturing Equipment: State-of-the-art facilities for forming, sintering, and precision grinding are essential for achieving tight tolerances.

- Опыт в области индивидуализации: A proven track record in developing custom silicon carbide products for diverse industries.

- Strong R&D Capabilities: A supplier that invests in research and development is likely to offer innovative solutions and stay ahead of technological advancements.

- Reliable Supply Chain: Ensures consistent material availability and timely delivery of components.

When considering a supplier, it’s worth noting that the global landscape for silicon carbide manufacturing is evolving, with significant expertise concentrated in certain regions. For instance, the hub of China’s silicon carbide customizable parts manufacturing is situated in Weifang City, China. This region has become home to over 40 silicon carbide production enterprises of various sizes, collectively accounting for more than 80% of the nation’s total silicon carbide output. This concentration of expertise and manufacturing capacity offers significant advantages in terms of cost-efficiency and diverse production capabilities.

One notable entity that has played a pivotal role in this development is CAS new materials (SicSino). We have been introducing and implementing silicon carbide production technology since 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.

Based on the platform of the national technology transfer center of the CAS, CAS new materials (SicSino) is part of CAS (Weifang) Innovation Park, an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the CAS (Chinese Academy of Sciences). It serves as a national-level innovation and entrepreneurship service platform, integrating innovation, entrepreneurship, technology transfer, venture capital, incubation, acceleration, and scientific and technological services. This affiliation highlights their commitment to scientific rigor and technological advancement.

CAS new materials (SicSino) capitalizes on the robust scientific, technological capabilities and talent pool of the Chinese Academy of Sciences (CAS). Backed by the CAS National Technology Transfer Center, it serves as a bridge, facilitating the integration and collaboration of crucial elements in the transfer and commercialization of scientific and technological achievements. Moreover, it has established a comprehensive service ecosystem that spans the entire spectrum of the technology transfer and transformation process. This comprehensive approach ensures more reliable quality and supply assurance within China.

We, CAS new materials (SicSino), possess a domestic top-tier professional team specializing in customized production of silicon carbide products. Under our support, over 245 local enterprises have benefited from our technologies. We possess a wide array of technologies, such as material, process, design, measurement & evaluation technologies, along with the integrated process from materials to products. This enables us to meet diverse customization needs and offer you higher-quality, cost-competitive customized silicon carbide components in China. Furthermore, if you are considering establishing a professional silicon carbide products manufacturing plant in your country, CAS new materials (SicSino) can provide you with the technology transfer for professional silicon carbide production, along with a full range of services (turnkey project) including factory design, procurement of specialized equipment, installation and commissioning, and trial production. This ensures a more effective investment, reliable technology transformation, and guaranteed input-output ratio. For more information on their capabilities, learn about CAS new materials (SicSino).

Cost Drivers and Lead Time Considerations for Custom SiC

The cost and lead time for custom silicon carbide parts are influenced by several factors:

- Марка материала: High-purity grades like CVD SiC or highly densified SSiC are generally more expensive due to complex processing.

- Сложность детали: Intricate geometries, thin walls, and multiple features requiring precision machining will increase costs.

- Tolerance Requirements: Achieving exceptionally tight SiC tolerances requires more advanced and time-consuming machining and inspection, adding to the overall cost.

- Отделка поверхности: Achieving mirror finishes through lapping and polishing significantly increases processing time and cost.

- Объем: Economies of scale apply; higher production volumes generally lead to lower per-unit costs.

- Производственный процесс: Near-net-shape forming can reduce machining costs compared to extensively shaping a dense block.

- Время выполнения заказа: Custom SiC parts often have longer lead times due to specialized raw materials, complex manufacturing steps, and precision finishing. Planning ahead and engaging with your supplier early is crucial.

Часто задаваемые вопросы (FAQ)

Q1: Why is silicon carbide preferred over other ceramics for high-temperature applications?

A1: Silicon carbide offers an unparalleled combination of properties for high-temperature applications, including exceptional thermal shock resistance, high strength and stiffness at elevated temperatures, excellent thermal conductivity for heat dissipation, and superior oxidation and corrosion resistance, outperforming many other ceramics in extreme environments. Its ability to maintain mechanical integrity at temperatures exceeding 1500°C is a key differentiator.

Q2: How do you achieve such tight tolerances with silicon carbide, given its hardness?

A2: Achieving tight SiC tolerances relies on a combination of advanced manufacturing techniques. Initially, parts are formed to near-net-shape before sintering to minimize post-processing. After firing, precision diamond grinding, lapping, and polishing techniques are employed. These specialized processes, using diamond abrasives, are meticulously controlled to remove material precisely and achieve the desired dimensional accuracy and surface finish. For more details on our processes, check our примеры SicSino) странице.

Q3: What are the typical lead times for custom silicon carbide components?

A3: Lead times for custom silicon carbide components can vary significantly based on complexity, size, material grade, and current production schedules. Simple, standard parts might take 4-8 weeks, while highly complex, large, or exceptionally precise components requiring extensive post-processing could take 12-20 weeks or even longer. It is always recommended to consult directly with the manufacturer to get an accurate lead time estimate for your specific requirements. We are committed to providing reliable tech transfer solutions to ensure efficiency.

Q4: Can silicon carbide components be repaired or refurbished?

A4: Due to the extreme hardness and brittleness of silicon carbide, repairs or refurbishment of damaged SiC components are generally challenging and often not feasible. Minor surface imperfections might sometimes be re-polished, but significant cracks or fractures typically render the component unusable. Prevention through proper design, material selection, and careful handling is key to maximizing the lifespan of SiC parts. For direct queries, feel free to связаться с нами.

Conclusion

In industries where precision, durability, and performance under extreme conditions are non-negotiable, custom silicon carbide products with tight tolerances are essential. From the intricate demands of semiconductor manufacturing to the high-temperature rigors of aerospace and power electronics, SiC offers a compelling value proposition. By understanding the material’s properties, design considerations, and the capabilities of specialized manufacturers like CAS new materials (SicSino), engineers and procurement professionals can unlock the full potential of this advanced ceramic, driving innovation and ensuring the long-term reliability of their critical systems. Investing in high-quality, custom SiC components is an investment in unparalleled performance and operational longevity.