SiC Additive Manufacturing: The Parts Revolution Is Here

Share

SiC Additive Manufacturing: The Parts Revolution Is Here

Introduction: What is SiC Additive Manufacturing and Why is it a Game-Changer?

Silicon Carbide (SiC) Additive Manufacturing (AM), often referred to as 3D printing, is a transformative technology that involves building SiC components layer by layer directly from digital models. Unlike traditional subtractive manufacturing processes that rely on machining material away from a larger block, SiC AM constructs parts by adding material, typically SiC powder combined with binders or through direct sintering/melting techniques. This approach unlocks unprecedented design freedom, enabling the creation of highly complex geometries, internal channels, and lightweight structures that were previously impossible or prohibitively expensive to produce.

The significance of SiC additive manufacturing in high-performance industrial applications cannot be overstated. Silicon carbide itself is renowned for its exceptional properties: extreme hardness, high thermal conductivity, excellent resistance to wear and corrosion, and stability at high temperatures. However, traditional manufacturing of SiC parts can be challenging, time-consuming, and costly, especially for intricate designs. SiC AM revolutionizes this by:

- Enabling Rapid Prototyping: Engineers can quickly iterate designs, significantly reducing development cycles for custom SiC components.

- Facilitating Complex Geometries: Lattice structures, conformal cooling channels, and functionally graded materials become feasible, optimizing part performance.

- Reducing Material Waste: As an additive process, it uses only the material needed for the part, making it more sustainable and cost-effective, especially with a high-value material like SiC.

- On-Demand Production: Parts can be manufactured as needed, reducing inventory costs and lead times for specialized components.

For industries like semiconductors, aerospace, automotive, and energy, where performance under extreme conditions is critical, SiC additive manufacturing offers a paradigm shift. It allows for the creation of bespoke, high-performance SiC parts tailored to specific application demands, pushing the boundaries of innovation and efficiency. This technology is not just an alternative manufacturing method; it’s a catalyst for developing next-generation components and systems.

The Evolution: From Traditional SiC to Additive Manufacturing

The journey of silicon carbide component manufacturing has been one of continuous innovation, driven by the demanding requirements of advanced industries. Traditionally, producing SiC parts involved several complex and often lengthy processes:

- Reaction Bonding (RBSiC): This involves infiltrating a porous silicon carbide and carbon preform with molten silicon. While it produces dense parts with good mechanical properties, design complexity is limited, and residual silicon can affect performance in certain chemical environments or at very high temperatures.

- Sintering (SSiC, LPSSiC): SiC powder is compacted and then fired at high temperatures (often above 2000°C) to cause densification. This can produce very pure SiC with excellent properties, but achieving full density without additives can be challenging, and shrinkage during sintering requires careful design considerations. Liquid Phase Sintering (LPSSiC) uses additives to lower the sintering temperature.

- Chemical Vapor Deposition (CVD-SiC): This process creates ultra-pure, dense SiC coatings or bulk parts by reacting precursor gases on a heated substrate. While excellent for purity and specific applications like semiconductor components, it’s generally slow and expensive for larger or complex 3D parts.

- Hot Pressing / Hot Isostatic Pressing (HIP): Applying high temperature and pressure simultaneously can produce highly dense SiC parts. However, these methods are typically limited to simpler shapes and can be costly.

These traditional methods, while effective for many applications, often face limitations in terms of:

- Design Freedom: Complex internal features, undercuts, or lattice structures are difficult or impossible to create.

- Lead Times: Tooling, multi-step processing, and machining can lead to long lead times, especially for custom designs.

- Material Waste: Subtractive processes inherently generate significant material waste, which is costly with an advanced material like SiC.

- Cost of Complexity: The cost of manufacturing increases dramatically with design intricacy.

Silicon Carbide Additive Manufacturing emerges as a disruptive force, overcoming many of these limitations. By building parts layer-by-layer, SiC AM offers:

- Unparalleled Design Complexity: Internal cooling channels, optimized flow paths, and lightweight lattice structures can be directly fabricated.

- Rapid Iteration and Customization: Prototypes and custom parts can be produced much faster without the need for extensive tooling.

- Reduced Material Waste: Being an additive process, material usage is optimized, significantly cutting down on waste.

- Consolidation of Parts: Assemblies of multiple components can often be redesigned and printed as a single, integrated part, improving reliability and reducing assembly costs.

While SiC AM is still evolving, with ongoing research in materials, processes (such as binder jetting, vat photopolymerization, and direct energy deposition adapted for ceramics), and post-processing, its potential to redefine how high-performance SiC components are designed and manufactured is undeniable. It complements traditional methods by offering solutions where complexity and speed are paramount.

Unlocking Material Advantages: Why SiC for Additive Manufacturing?

Silicon Carbide (SiC) is a premier advanced ceramic material, and its inherent properties make it exceptionally well-suited for producing high-performance components through additive manufacturing. The ability to leverage these properties in complex, custom-designed parts is a key driver for the adoption of SiC AM across various demanding industries. The primary material advantages of SiC that shine in AM applications include:

- Exceptional Hardness and Wear Resistance: SiC is one of the hardest commercially available materials, ranking close to diamond. This makes AM-produced SiC parts highly resistant to abrasive wear, erosion, and sliding friction. Applications like nozzles, bearings, seals, and grinding components benefit immensely.

- High Thermal Conductivity: Unlike many ceramics that are thermal insulators, SiC exhibits high thermal conductivity. This allows AM SiC parts to efficiently dissipate heat, making them ideal for heat exchangers, semiconductor processing equipment, and components in high-temperature engines or power electronics where thermal management is critical. AM allows for the design of intricate cooling channels to maximize this property.

- Excellent High-Temperature Strength and Stability: SiC maintains its mechanical strength and structural integrity at very high temperatures (often exceeding 1400°C). This makes SiC AM parts suitable for furnace components, turbine blades, rocket nozzles, and other applications in extreme thermal environments.

- Superior Chemical Inertness and Corrosion Resistance: SiC is highly resistant to a wide range of acids, alkalis, and molten salts. AM SiC components can thus be used in harsh chemical processing environments, for handling corrosive fluids, and in applications where chemical stability is paramount.

- Low Thermal Expansion Coefficient: SiC has a relatively low coefficient of thermal expansion, which means it experiences minimal dimensional changes with temperature fluctuations. This provides excellent thermal shock resistance, crucial for applications involving rapid heating and cooling cycles.

- High Stiffness (Young’s Modulus): SiC is a very stiff material, meaning it resists deformation under load. This is advantageous for precision components, structural elements, and applications requiring high dimensional stability.

- Potential for Electrical Conductivity Control: While typically a semiconductor, the electrical properties of SiC can be tailored through doping and processing, allowing for applications ranging from insulators to resistive heating elements or components in power devices. AM could potentially offer localized control of these properties in the future.

Additive manufacturing techniques for SiC aim to harness these intrinsic material benefits while adding the advantages of design flexibility and rapid production. The choice of specific SiC powder characteristics (particle size, morphology, purity) and AM process parameters (e.g., binder jetting followed by infiltration and sintering, or direct powder bed fusion techniques) is crucial to achieving the desired density and final properties in the 3D printed SiC part. The ability to create near-net-shape parts with complex internal features using such a robust material is revolutionizing component design in many engineering fields.

Transformative Applications of SiC AM Parts Across Industries

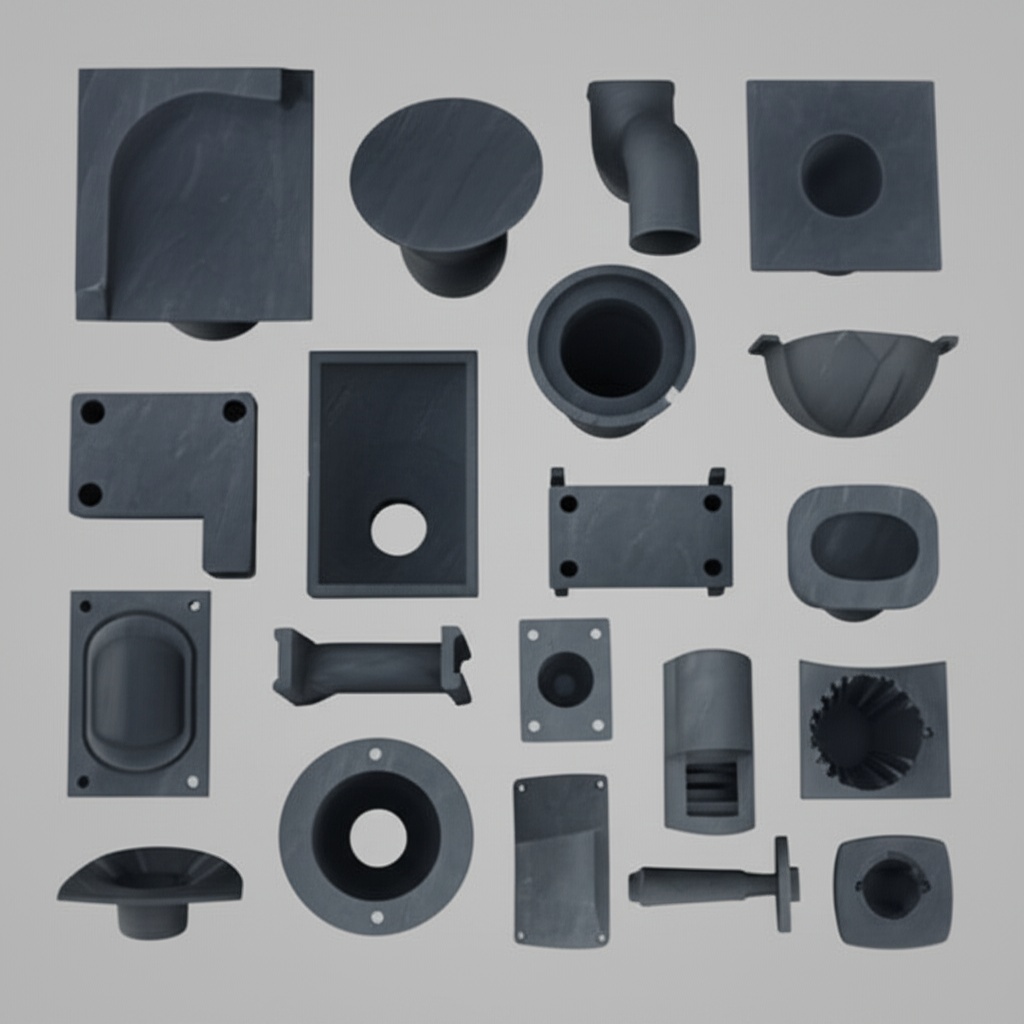

The unique combination of silicon carbide’s outstanding material properties and the design freedom afforded by additive manufacturing is unlocking new possibilities and enhancing existing applications across a multitude of high-tech industries. Custom SiC AM parts are becoming indispensable where extreme conditions and complex geometries meet. Key industries benefiting include:

Semiconductor Manufacturing:

- Wafer Chucks and End Effectors: AM allows for lightweight designs with intricate vacuum channels and optimized thermal uniformity for wafer processing. High stiffness and wear resistance are critical.

- Gas Showerheads and Injection Nozzles: Complex internal geometries for uniform gas distribution in deposition and etching processes can be precisely fabricated. Chemical inertness is key.

- Precision Alignment Components: High stiffness and thermal stability ensure dimensional accuracy in lithography and metrology equipment.

Aerospace and Defense:

- Rocket Nozzles and Thruster Components: High-temperature strength, thermal shock resistance, and erosion resistance are vital. AM enables complex cooling channels and lightweight designs.

- Leading Edges and Hypersonic Vehicle Components: Resistance to extreme temperatures and abrasion during high-speed flight.

- Mirror Substrates and Optical Benches: High stiffness, low thermal expansion, and the ability to create lightweighted structures are beneficial for space-based optics and reconnaissance systems.

- Custom Armor Components: SiC’s hardness and lightweight nature make it suitable for specialized ballistic protection.

Automotive (especially Electric Vehicles and Performance):

- Power Electronics Components: Substrates, heat sinks, and housings for inverters and converters benefit from SiC’s high thermal conductivity and electrical insulation. AM allows for integrated cooling.

- Brake System Components: Wear-resistant and lightweight brake discs or pads for high-performance vehicles.

- Turbocharger Components: Rotors and other parts requiring high-temperature strength and wear resistance.

Energy (Renewable and Traditional):

- Heat Exchangers and Recuperators: Complex geometries for enhanced heat transfer efficiency in concentrated solar power, fuel cells, and advanced gas turbines. High-temperature stability and corrosion resistance are crucial.

- Burner Nozzles and Combustion Chamber Liners: For industrial burners and gas turbines, SiC AM parts offer superior durability and performance at high temperatures.

- Nuclear Energy Components: Fuel cladding and structural components due to SiC’s radiation resistance and high-temperature stability.

Industrial Manufacturing and Chemical Processing:

- Wear-Resistant Components: Nozzles, seals, bearings, pump components, and cyclone liners for abrasive or corrosive media. AM allows for tailored wear solutions.

- Furnace Furniture and Kiln Components: Beams, rollers, and supports with excellent high-temperature strength and thermal shock resistance.

- Chemical Reactors and Mixers: Components requiring extreme corrosion resistance and potentially complex internal structures for optimized flow or catalytic reactions.

LED Manufacturing:

- Susceptors and Crucibles: Used in MOCVD reactors for LED growth, requiring high purity, thermal uniformity, and chemical stability. AM can provide custom designs for improved yields.

The table below summarizes some key applications and the enabling SiC AM benefits:

| Industry | Example Application | Key SiC AM Benefits Utilized |

|---|---|---|

| Semiconductor | Wafer chucks, showerheads | Complex internal channels, thermal uniformity, chemical inertness, stiffness |

| Aerospace | Rocket nozzles, leading edges | High-temperature strength, thermal shock resistance, complex cooling, lightweighting |

| Automotive (EVs) | Power electronic heat sinks | High thermal conductivity, integrated cooling channels, electrical insulation |

| Energy | Heat exchangers, burner nozzles | Complex geometries for efficiency, high-temperature strength, corrosion resistance |

| Industrial | Wear parts, furnace components | Extreme wear resistance, high-temperature stability, custom designs |

This widespread adoption highlights the versatility of SiC additive manufacturing in creating solutions for some of the most challenging engineering problems, pushing performance limits and enabling innovation. For companies in these sectors, exploring customizing support for SiC AM parts can provide a significant competitive advantage.

The AM Edge: Benefits of SiC Additive Manufacturing Over Conventional Routes

While traditional methods of manufacturing silicon carbide components have served industries well for decades, SiC Additive Manufacturing (AM) presents a paradigm shift, offering distinct advantages, particularly when complexity, speed, and customization are critical. The “AM Edge” lies in its ability to overcome many inherent limitations of conventional subtractive and forming techniques.

Key benefits of SiC AM include:

-

Unprecedented Design Freedom & Complexity:

This is perhaps the most significant advantage. AM allows for the creation of intricate internal channels, lattice structures, functionally graded materials, and organic shapes that are impossible or prohibitively expensive to produce using traditional methods like machining, casting, or sintering of pressed powders. This enables:- Optimized fluid flow paths in nozzles or heat exchangers.

- Conformal cooling channels for superior thermal management.

- Lightweighting through topology optimization without sacrificing strength.

- Part consolidation, reducing assembly steps and potential points of failure.

-

Rapid Prototyping and Shorter Lead Times:

SiC AM can produce functional prototypes or end-use parts directly from a CAD model in days rather than weeks or months. This drastically accelerates design iteration cycles, allowing engineers to test and refine concepts quickly. The elimination of tooling (molds, dies) for small to medium production runs further reduces lead times for custom SiC components. -

Reduced Material Waste:

Traditional subtractive manufacturing can waste a significant amount of raw material, especially with complex parts. SiC is a relatively expensive advanced material, so minimizing waste is crucial. AM, being an additive process, uses only the material necessary to build the part, leading to substantial cost savings and a more sustainable manufacturing approach. This is often referred to as near-net-shape manufacturing. -

Mass Customization and On-Demand Manufacturing:

SiC AM is ideally suited for producing highly customized parts or small batches with unique designs without the economic penalties associated with traditional manufacturing setups. This facilitates on-demand production, reducing the need for large inventories and allowing for tailored solutions for specific customer requirements. -

Cost-Effectiveness for Complex Parts:

While the raw material for SiC AM can be specialized and the machines sophisticated, for parts with high geometric complexity, AM can be more cost-effective than traditional methods. The cost in AM is driven more by the volume of material used and print time, rather than the complexity of machining operations or tooling creation. -

Potential for Functionally Graded Materials (FGM):

Some AM techniques hold the promise of creating parts with varying material compositions or densities within a single component. For SiC, this could mean tailoring specific areas for different properties, such as enhanced thermal conductivity in one section and higher wear resistance in another, all within a monolithic part. -

Accessibility to Advanced Materials:

AM can sometimes make it easier to work with materials like SiC that are difficult to machine due to their hardness. While challenges in printing SiC exist, AM processes are being continuously refined to handle such advanced ceramics effectively.

In summary, SiC additive manufacturing offers a compelling alternative to conventional routes, particularly for applications demanding intricate designs, rapid turnaround, and efficient material utilization. While traditional methods will continue to be essential for high-volume production of simpler shapes, the AM edge provides engineers and designers with a powerful new tool to innovate and optimize high-performance silicon carbide components.

Navigating SiC Materials for Additive Manufacturing Processes

The success of Silicon Carbide Additive Manufacturing (SiC AM) heavily relies on the quality and characteristics of the SiC raw materials used, as well as the specific AM process employed. Unlike metals or polymers, ceramics like SiC present unique challenges and opportunities in AM due to their high melting points, brittleness, and specific sintering behaviors.

Key considerations for SiC materials in AM include:

1. SiC Powder Characteristics:

- Purity: High purity SiC powders (often >99%) are crucial for achieving optimal mechanical, thermal, and chemical properties in the final part. Impurities can act as defect sites or alter sintering behavior.

- Particle Size Distribution (PSD): A well-controlled PSD is vital for good powder bed packing density (in powder bed fusion or binder jetting) and flowability. Finer particles generally aid sintering but can pose challenges in handling and spreading.

- Particle Morphology: Spherical or near-spherical particles tend to have better flowability and packing density compared to angular or irregular particles.

- Alpha (α-SiC) vs. Beta (β-SiC) Phases: α-SiC is the more stable high-temperature polymorph and is commonly used. β-SiC can transform to α-SiC at high temperatures. The choice can influence sintering kinetics and final microstructure.

2. Common SiC AM Routes and Associated Material Forms:

-

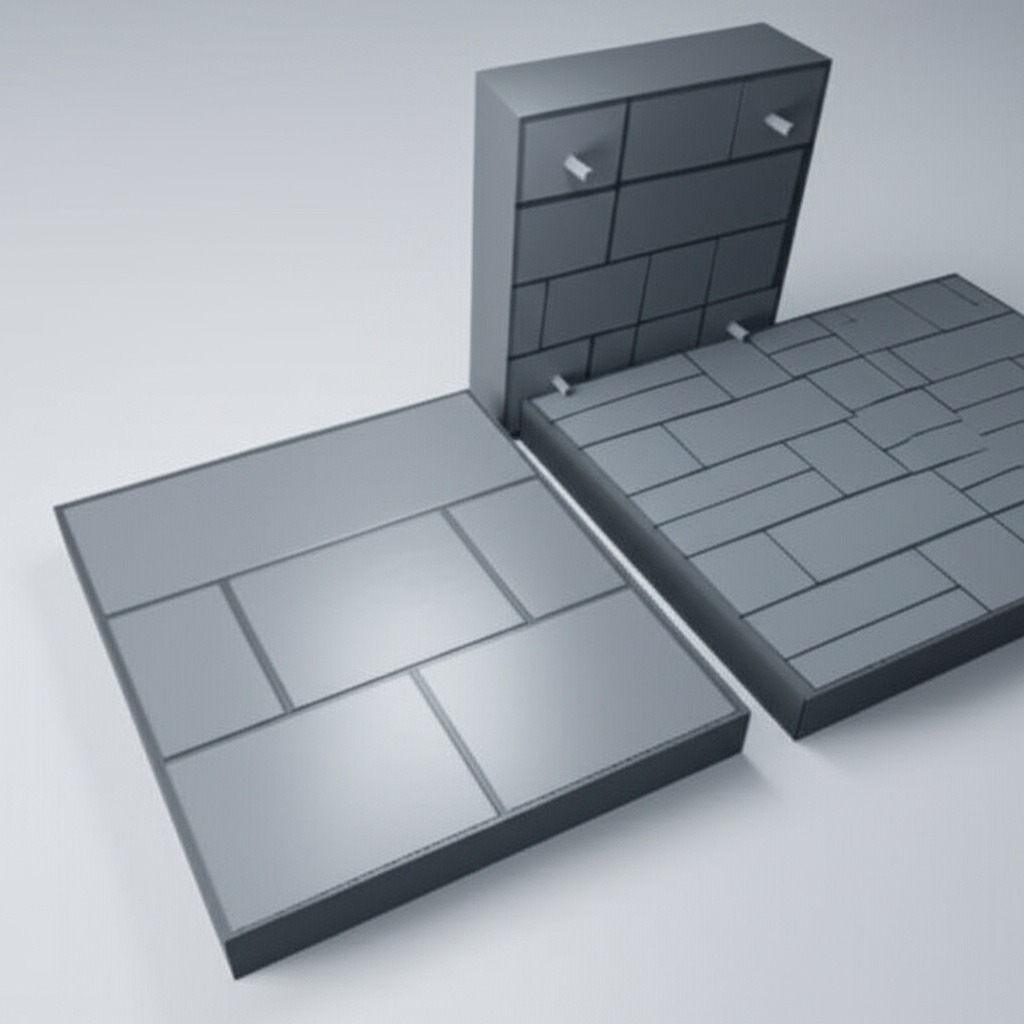

Binder Jetting Technology (BJT):

This is one of the more mature AM processes for ceramics. It involves selectively jetting a binder into a bed of SiC powder. The “green” part is then cured and subsequently subjected to post-processing, typically:- Infiltration: The porous preform can be infiltrated with molten silicon (leading to Reaction Bonded SiC – RBSiC like material) or other precursor materials that convert to SiC or a SiC matrix composite upon heating. Silicon infiltration is common due to its ability to achieve high density.

- Sintering: If sinterable SiC powder is used with a fugitive binder, the part can be debound and sintered at high temperatures to achieve a dense Sintered SiC (SSiC) or Liquid Phase Sintered SiC (LPSSiC) part. This often requires specialized SiC powders with sintering additives.

-

Vat Photopolymerization (e.g., Stereolithography – SLA, Digital Light Processing – DLP):

In these processes, SiC particles are dispersed in a photocurable resin. A light source selectively polymerizes the resin, layer by layer, creating a green part. This is followed by:- Debinding: Thermal removal of the polymer binder.

- Sintering: High-temperature firing to densify the SiC particles. Achieving high SiC loading in the resin while maintaining suitable viscosity is a key challenge.

-

Direct Energy Deposition (DED) / Powder Bed Fusion (PBF – e.g., Selective Laser Sintering/Melting – SLS/SLM):

Directly sintering or melting SiC powder using a laser or electron beam is challenging due to SiC’s high melting point (it typically decomposes before melting at atmospheric pressure) and high thermal conductivity. However, research is ongoing:- SLS for SiC: Often involves using SiC powders mixed with sintering aids or transient binders that can be removed. Full densification usually requires significant post-processing.

- Reactive SLS/SLM: Using mixtures of powders (e.g., silicon and carbon) that react in-situ under the laser to form SiC.

-

Material Extrusion (e.g., Fused Deposition Modeling – FDM like processes):

This involves extruding a filament or paste composed of SiC powder and a binder system. The green part is then debound and sintered, similar to metal injection molding (MIM) or ceramic injection molding (CIM) principles.

3. Resulting Material Properties:

The final properties of the AM SiC part (density, strength, thermal conductivity, etc.) are highly dependent on the chosen AM process and the subsequent post-processing steps. For instance:

- SiC parts produced via binder jetting followed by silicon infiltration (RBSiC-like) will contain some free silicon, affecting their maximum service temperature and chemical resistance in certain environments.

- Parts produced by sintering (after binder jetting, vat photopolymerization, or material extrusion) can achieve very high SiC purity and density, leading to properties closer to conventionally sintered SiC. However, achieving near-full density can be challenging and may involve significant shrinkage.

Navigating these material and process options requires expertise. Partnering with a knowledgeable supplier who understands the nuances of SiC powders, AM process capabilities, and post-processing is crucial for obtaining functional parts that meet application requirements. These suppliers can advise on the best approach to achieve specific grades like reaction-bonded SiC, sintered SiC, or even nitride-bonded silicon carbide (NBSC) if applicable AM routes are developed.

Designing for Success: Optimizing Parts for SiC Additive Manufacturing

Additive manufacturing with silicon carbide (SiC AM) unlocks remarkable design freedom, but realizing its full potential requires adherence to Design for Additive Manufacturing (DfAM) principles tailored for ceramics. Unlike traditional manufacturing, where complexity often increases cost, AM can produce intricate geometries with relative ease. However, SiC’s material properties and the specifics of AM processes impose certain design considerations that engineers must understand to create successful, functional parts.

Key Design Considerations for SiC AM:

-

Embrace Geometric Complexity:

- Internal Channels: Design complex cooling channels, manifolds, or microreactors. Consider channel shape (avoid sharp corners for stress and printability), diameter, and accessibility for post-processing (e.g., powder removal).

- Lattice Structures: Utilize lattice or topology-optimized structures for lightweighting while maintaining stiffness. Ensure strut thickness and cell size are within the printable limits of the chosen SiC AM process.

- Part Consolidation: Redesign assemblies into single, integrated components to reduce part count, eliminate joints (potential failure points), and simplify assembly.

-

Wall Thickness and Feature Size:

- Minimum Wall Thickness: Each SiC AM process has limitations on the thinnest wall that can be reliably built. This is influenced by powder particle size, layer thickness, and green part handling. Typically, this ranges from 0.5 mm to a few millimeters.

- Minimum Feature Size: Small holes, pins, or intricate details also have resolution limits. Consult with your AM provider for specific guidelines.

- Aspect Ratios: Tall, thin walls can be prone to warping or failure during printing or post-processing. Consider adding ribs or changing orientation.

-

Overhangs and Support Structures:

- Self-Supporting Angles: Most powder-bed AM processes allow for some degree of overhang without supports (typically up to 45 degrees from horizontal). Designs should maximize self-supporting features.

- Support Strategy (if needed): For ceramics like SiC, supports (if required by the specific AM technique, e.g., some vat photopolymerization or extrusion methods) can be challenging to remove due to the material’s hardness. Designs should minimize the need for supports or make them easily accessible for removal. Binder jetting often uses the surrounding powder as support, simplifying this aspect.

-

Shrinkage and Distortion:

- SiC parts, especially those undergoing sintering after printing (e.g., via binder jetting, vat photopolymerization, or material extrusion), will experience significant shrinkage (typically 15-25%). This must be accurately accounted for in the initial design by scaling the part up.

- Non-uniform shrinkage can lead to distortion or cracking. Aim for uniform wall thicknesses and avoid large, solid masses where possible. Consult with AM specialists for shrinkage models.

-

Stress Concentrations:

- Avoid sharp internal corners; use fillets and radii to reduce stress concentrations, which can be critical in brittle materials like SiC. This is important during both mechanical loading and thermal cycling.

-

Powder Removal (for Powder Bed Processes):

- If using binder jetting or powder bed fusion, ensure that internal cavities and channels have escape holes for unbonded powder removal. Complex, trapped volumes can be impossible to clear.

-

Orientation and Layering Effects:

- Part orientation during the build can affect surface finish, dimensional accuracy, and potentially mechanical properties due to the anisotropic nature of layer-by-layer construction. Discuss optimal orientation with your AM service provider.

-

Tolerances and Surface Finish (as-printed vs. post-processed):

- Understand the “as-printed” tolerances and surface finish achievable by the specific SiC AM process. Plan for post-processing steps like grinding, lapping, or polishing if tighter tolerances or smoother surfaces are required. Design features that allow for easy access for these operations.

Collaborating closely with an experienced SiC AM provider during the design phase is highly recommended. They can offer insights specific to their equipment and processes, helping to optimize the design for manufacturability, cost-effectiveness, and performance. Taking these DfAM principles into account will ensure that the revolutionary potential of SiC additive manufacturing is fully harnessed for your components.

Precision and Perfection: Tolerances, Surface Finish, and Post-Processing in SiC AM

While Silicon Carbide Additive Manufacturing (SiC AM) offers un

SicSino – CAS new materials

We, CAS new materials(SicSino), have been introducing and implementing silicon carbide production technology since the 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.