SiC Hot Pressing for Ultra-Dense Components

Share

SiC Hot Pressing for Ultra-Dense Components: The Ultimate Guide

In the realm of advanced materials, silicon carbide (SiC) stands out for its exceptional properties, making it indispensable across a multitude of demanding industrial applications. Among the various manufacturing techniques for SiC components, hot pressing is a critical process for achieving near-theoretical density, superior mechanical strength, and enhanced performance characteristics. This guide delves into the intricacies of SiC hot pressing, exploring its applications, advantages, design considerations, and how to choose the right manufacturing partner for your custom SiC needs, particularly for industries ranging from semiconductor manufacturing and aerospace to renewable energy and chemical processing.

Understanding SiC Hot Pressing: The Science Behind Superior Density

Silicon carbide hot pressing is an advanced powder metallurgy process used to fabricate highly dense and robust SiC components. The technique involves the simultaneous application of high temperature and uniaxial pressure to SiC powder within a die. This combination facilitates the consolidation and densification of the powder particles, significantly reducing porosity and leading to components with near-net shapes and exceptional material properties.

The process typically occurs in a controlled atmosphere (often inert gas like argon or nitrogen) or vacuum to prevent oxidation and contamination at elevated temperatures, which can range from 1800°C to 2200°C (3272°F to 3992°F). Pressures applied can vary from 20 to 50 MPa (2900 to 7250 psi). Sintering aids, such as boron, carbon, or alumina, are often added in small quantities to the SiC powder to promote densification by facilitating atomic diffusion and grain boundary sliding, which are crucial mechanisms for eliminating pores and achieving high density.

The result is a fine-grained microstructure with minimal porosity, leading to significant improvements in mechanical strength, hardness, wear resistance, and thermal conductivity compared to other SiC manufacturing methods like reaction bonding or conventional sintering (pressureless sintering).

Why Ultra-Dense SiC Components are Critical for High-Performance Applications

The density of a ceramic component is directly correlated with its performance, particularly in harsh operating environments. Ultra-dense SiC components, typically achieving >99% of theoretical density through hot pressing, offer several critical advantages:

- Enhanced Mechanical Strength: Higher density means fewer internal flaws (pores) that can act as stress concentrators, leading to significantly increased flexural strength, fracture toughness, and overall structural integrity. This is vital for components subjected to high mechanical loads or impacts.

- Superior Wear Resistance: The inherent hardness of silicon carbide, combined with high density, results in exceptional resistance to abrasive and erosive wear. This makes hot-pressed SiC ideal for applications like nozzles, seals, bearings, and grinding media.

- Improved Thermal Properties: Dense SiC exhibits excellent thermal shock resistance and high thermal conductivity. This allows components to withstand rapid temperature changes and efficiently dissipate heat, crucial for heat exchangers, furnace components, and power electronics substrates.

- Increased Chemical Inertness and Corrosion Resistance: Reduced porosity minimizes the surface area exposed to corrosive agents, enhancing the material’s resistance to chemical attack from acids, alkalis, and molten metals. This is paramount in chemical processing equipment and metallurgical applications.

- Gas Impermeability: The near-zero porosity of hot-pressed SiC makes it impermeable to gases and liquids, essential for applications like vacuum chucks, gas bearings, and seals in high-vacuum or high-pressure environments.

- Dimensional Stability: High-density SiC maintains its shape and dimensions even under extreme temperatures and mechanical stress, ensuring reliability and precision in critical applications.

These enhanced properties make ultra-dense hot-pressed SiC the material of choice for applications where performance, reliability, and longevity are non-negotiable.

Key Industrial Applications of Hot-Pressed Silicon Carbide

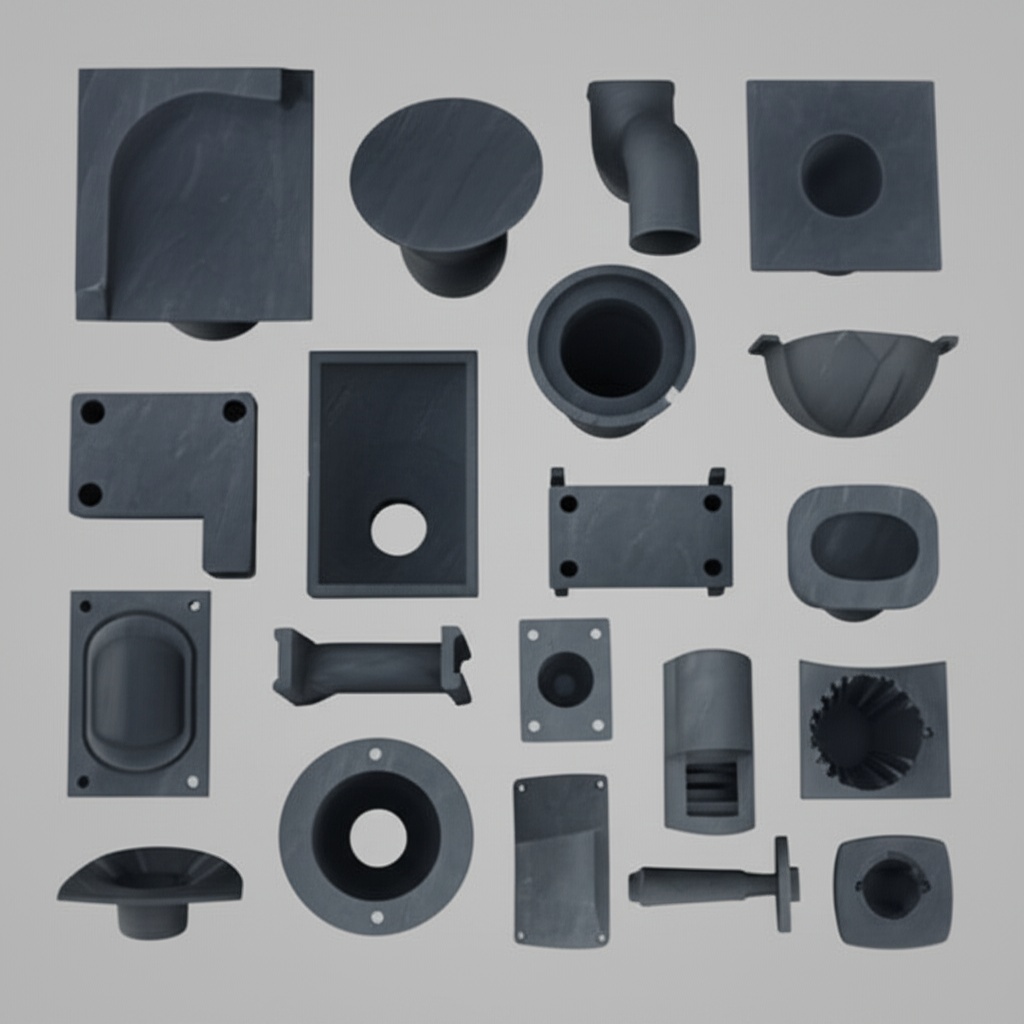

The unique combination of properties offered by hot-pressed SiC makes it suitable for a wide array of demanding applications across various industries. Procurement managers and technical buyers in the following sectors often specify hot-pressed SiC for their most critical components:

| Industry | Key Applications of Hot-Pressed SiC | Benefits Sought |

|---|---|---|

| Semiconductor Manufacturing | Wafer chucks (electrostatic and vacuum), focus rings, edge rings, showerheads, CMP (Chemical Mechanical Planarization) rings, dummy wafers, robotic end effectors | High purity, dimensional stability, thermal conductivity, plasma erosion resistance, wear resistance |

| Aerospace & Defense | Rocket nozzles, missile radomes, armor plates (ballistic protection), reconnaissance mirror substrates, components for hypersonic vehicles, turbine engine components | High-temperature strength, thermal shock resistance, lightweight, stiffness, wear resistance, specific defense material requirements |

| Power Electronics & Electrical Systems | Heat sinks, substrates for power modules, insulator components, high-voltage switchgear components | High thermal conductivity, electrical insulation, high breakdown voltage, thermal stability |

| High-Temperature Processing & Furnaces | Crucibles, setters, kiln furniture, burner nozzles, thermocouple protection tubes, heating elements, furnace linings | Extreme temperature resistance, thermal shock resistance, chemical inertness, mechanical strength at high temperatures |

| Industrial Manufacturing & Machinery | Mechanical seals, bearings (sliding and ball), pump components (shafts, sleeves), nozzles (sandblasting, water jet), wear liners, cutting tool inserts, valve components | Exceptional wear and abrasion resistance, corrosion resistance, high hardness, dimensional stability |

| Metallurgy | Components for handling molten metals (e.g., aluminum, copper), thermocouple sheaths, crucibles for non-ferrous metals | Resistance to molten metal corrosion, high-temperature strength, thermal shock resistance |

| Chemical Processing | Pump components, valve parts, seals, heat exchanger tubes, reactor linings exposed to corrosive chemicals | Outstanding chemical inertness, corrosion resistance across a wide pH range, wear resistance |

| Renewable Energy & Energy Storage | Components for concentrated solar power (CSP) systems, parts for advanced battery systems, fuel cell components | High-temperature stability, thermal shock resistance, corrosion resistance |

| Oil and Gas | Wear parts for downhole drilling tools, valve components for abrasive fluid handling, sensor protection | Abrasion resistance, corrosion resistance, high pressure tolerance |

| LED Manufacturing | Susceptors for MOCVD reactors, wafer carriers | High thermal conductivity, temperature uniformity, chemical stability |

The versatility of hot-pressed SiC allows for tailored solutions that meet the specific performance criteria of these demanding industries, often replacing traditional materials like tungsten carbide, alumina, or specialty alloys.

Unlocking Performance: Advantages of Custom Hot-Pressed SiC Components

While standard SiC components are available, opting for custom hot-pressed SiC parts offers significant advantages, particularly when precise performance characteristics and complex geometries are required. Customization allows engineers and designers to leverage the full potential of SiC for their specific applications.

- Optimized Material Properties: Customization can involve tailoring the SiC powder formulation (e.g., purity, grain size, type and amount of sintering aids) to fine-tune properties like thermal conductivity, electrical resistivity, or fracture toughness to meet exact application requirements.

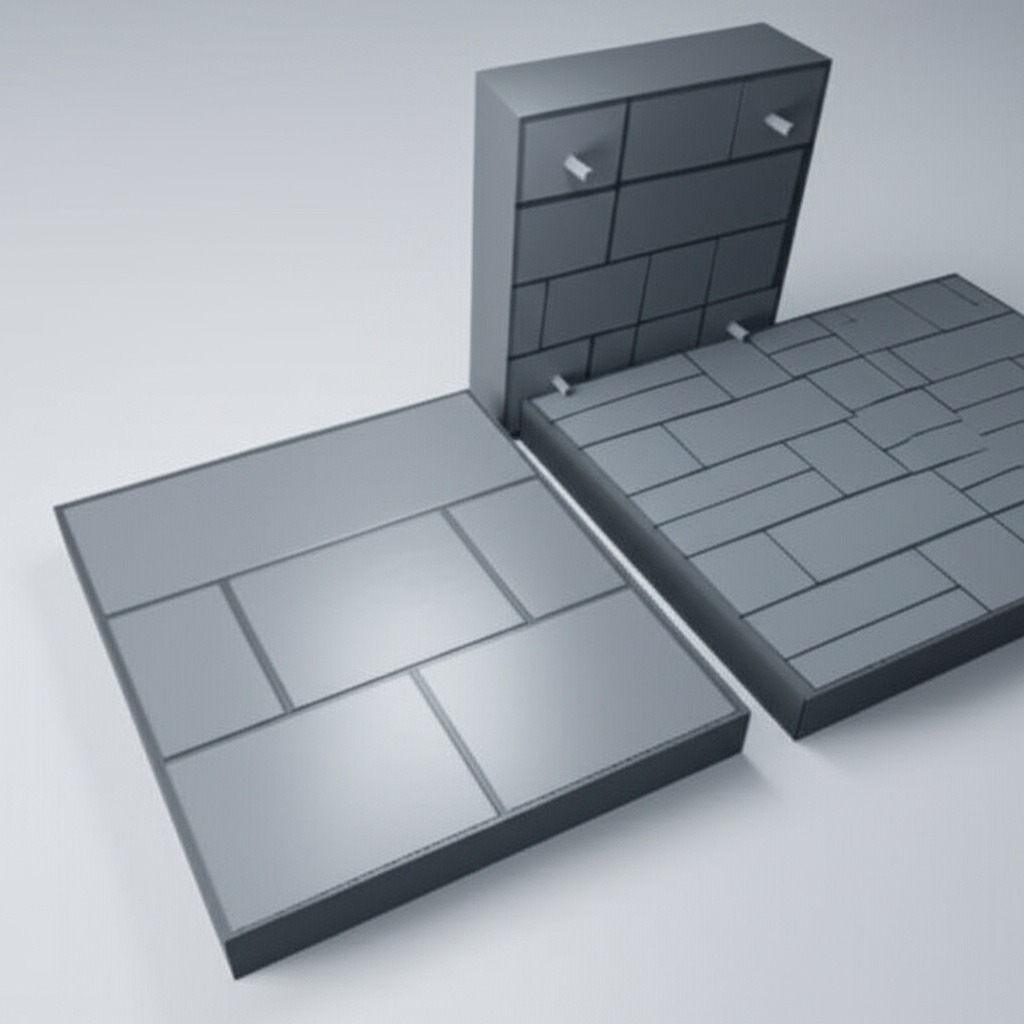

- Complex Geometries and Near-Net Shapes: The hot pressing process, combined with advanced tooling design, allows for the creation of intricate shapes and features that might be difficult or impossible to achieve with other manufacturing methods or require extensive post-machining. This reduces material waste and subsequent machining costs.

- Application-Specific Design: Components can be designed from the ground up to address unique operational challenges, integrating features that enhance performance, improve system integration, or extend service life.

- Improved Performance and Efficiency: Tailored SiC components often lead to better overall system performance, higher efficiency, and reduced downtime due to their optimized properties and design. For example, a custom-designed SiC seal can offer superior leakage control and longer life in a specific chemical pump.

- Consolidation of Parts: In some cases, multiple smaller parts made from different materials can be replaced by a single, custom-designed hot-pressed SiC component, simplifying assembly and improving reliability.

- Proprietary Designs: Customization protects intellectual property by creating components unique to a specific product or system, offering a competitive advantage.

Working with a supplier proficient in custom SiC solutions, from material formulation through to final finishing, is key to unlocking these benefits.

Navigating SiC Grades and Compositions for Hot Pressing

Several grades and compositions of silicon carbide can be utilized in the hot pressing process, each offering a distinct set of properties suitable for specific applications. The choice of grade is critical and depends on the required performance characteristics, operating environment, and cost considerations.

Common types include:

- Alpha Silicon Carbide (α-SiC): Predominantly used for hot pressing, α-SiC offers excellent high-temperature strength, hardness, and wear resistance. It is formed at higher temperatures and is the more stable polymorph.

- Beta Silicon Carbide (β-SiC): While less common for direct hot pressing of large parts due to its lower temperature formation, β-SiC powders can be used and often transform to α-SiC during the high-temperature hot pressing cycle. It can yield very fine-grained microstructures.

Key considerations when selecting a SiC grade for hot pressing include:

- Purity Levels: High-purity SiC (e.g., >99.5%) is crucial for semiconductor applications to prevent contamination. For other applications, industrial grades might be sufficient.

- Sintering Additives:

- Non-oxide additives: Boron (B) and Carbon (C) are commonly used. Boron carbide (B4C) is also a frequent choice. These promote solid-state sintering mechanisms, resulting in high-density SiC with excellent mechanical properties.

- Oxide additives: Alumina (Al2O3), Yttria (Y2O3), or other rare-earth oxides can be used to promote liquid-phase sintering. This can lower the required sintering temperature and pressure but may result in a glassy phase at the grain boundaries, which can affect high-temperature properties or chemical resistance. However, it can also enhance fracture toughness.

- Grain Size: The initial SiC powder’s grain size and the resulting grain size in the densified component significantly impact mechanical properties. Finer grain sizes generally lead to higher strength and hardness.

The table below summarizes common approaches and their typical characteristics:

| SiC Type / Additive System | Typical Density Achieved | Key Characteristics | Common Applications |

|---|---|---|---|

| Hot-Pressed α-SiC (with B and C) | >99% | Very high hardness, excellent wear resistance, good high-temperature strength, good thermal conductivity. | Wear parts, armor, semiconductor processing components, nozzles. |

| Hot-Pressed SiC with Oxide Additives (e.g., Al2O3, Y2O3) | >98.5% | Slightly lower hardness than B/C added SiC, potentially improved fracture toughness, can be sintered at lower temperatures. | Mechanical seals, some wear components, applications where slightly higher toughness is beneficial. |

Consulting with experienced material scientists and SiC manufacturers is crucial to select the optimal grade and additive system for your specific custom hot-pressed SiC components.

Critical Design Considerations for Manufacturing Hot-Pressed SiC Products

Designing components for SiC hot pressing requires careful consideration of the material’s characteristics and the manufacturing process to ensure functionality, manufacturability, and cost-effectiveness. Engineers should keep the following in mind:

- Geometry and Complexity:

- Simplicity is Key: While hot pressing can produce complex shapes, simpler geometries generally lead to lower tooling costs, easier manufacturing, and better dimensional control.

- Uniform Wall Thickness: Aim for uniform wall thicknesses to ensure even pressure distribution and consistent densification during the hot pressing cycle. Abrupt changes in thickness can lead to stress concentrations and cracking.

- Draft Angles: Incorporate slight draft angles (tapers) on vertical walls to facilitate easy removal of the part from the graphite die.

- Avoid Sharp Internal Corners: Use generous radii on internal corners to reduce stress concentrations, which can be initiation points for cracks in brittle materials like SiC.

- Tolerances: Understand that as-hot-pressed tolerances are typically wider than those achievable with post-machining. Design for the loosest acceptable tolerances to minimize post-processing costs. If tighter tolerances are essential, specify them clearly for subsequent grinding or lapping operations.

- Shrinkage: SiC powder undergoes significant shrinkage (typically 15-25%) during densification. This must be accurately accounted for in the die design. This is an area where experienced manufacturers excel.

- Machinability: SiC is extremely hard and brittle, making it challenging and costly to machine after hot pressing. Design features to be as “net-shape” as possible to minimize the need for extensive diamond grinding.

- Specify only critical surfaces for tight tolerances and fine finishes.

- Consider features that can be molded in versus machined.

- Stress Points: Identify potential stress points in the design and mitigate them through rounded corners, ribs, or thicker sections where appropriate. Finite Element Analysis (FEA) can be a valuable tool for optimizing designs for stress distribution.

- Joining and Assembly: If the SiC component needs to be assembled with other parts (ceramic or metallic), consider how this will be achieved. Methods like brazing, shrink-fitting, or mechanical fastening have specific design implications. Differential thermal expansion must be accounted for if joining to other materials.

Early collaboration with your SiC component manufacturer during the design phase is highly recommended. Their expertise in Design for Manufacturability (DFM) for hot-pressed SiC can save considerable time and cost, leading to a more robust and reliable product.

Achievable Tolerances, Surface Finish, and Dimensional Accuracy in Hot-Pressed SiC

The precision achievable with hot-pressed silicon carbide components depends on the initial hot pressing process and any subsequent finishing operations. Understanding these capabilities is crucial for procurement managers and engineers specifying these parts.

As-Hot-Pressed:

- Tolerances: Typical dimensional tolerances for as-hot-pressed SiC parts are generally in the range of ±0.5% to ±1% of the dimension, or ±0.1mm to ±0.5mm, whichever is greater. This depends heavily on the part size, complexity, and tooling quality.

- Surface Finish (Ra): The surface finish of as-pressed parts is largely determined by the surface of the graphite die used. It typically ranges from 1.6 to 6.3 µm Ra (63 to 250 µin Ra).

After Post-Processing (Grinding, Lapping, Polishing):

Due to its extreme hardness, machining SiC requires specialized diamond tooling and techniques. Post-processing can significantly improve tolerances and surface finish:

- Tolerances:

- Grinding: Can achieve tolerances down to ±0.005mm to ±0.025mm (±0.0002″ to ±0.001″).

- Lapping/Polishing: Can achieve even tighter tolerances, sometimes down to ±0.001mm (±0.00004″), especially for flatness and parallelism on critical surfaces.

- Surface Finish (Ra):

- Grinding: Can achieve finishes in the range of 0.2 to 0.8 µm Ra (8 to 32 µin Ra).

- Lapping: Can produce finishes from 0.05 to 0.2 µm Ra (2 to 8 µin Ra).

- Polishing: Can achieve exceptionally smooth, mirror-like finishes down to <0.01 µm Ra (<0.4 µin Ra), which is often required for optical components or semiconductor wafer chucks.

- Dimensional Accuracy & Geometric Features:

- Flatness and Parallelism: Can be controlled to within a few micrometers (or even sub-micrometer levels for optical applications) over significant surface areas using precision lapping and polishing.

- Roundness and Cylindricity: Precision grinding can achieve excellent roundness and cylindricity for shaft-like components.

- Hole Diameters and Locations: Can be precisely controlled with diamond drilling and grinding.

It’s important to specify only the necessary level of precision, as tighter tolerances and finer surface finishes significantly increase manufacturing costs due to the additional machining time and specialized equipment required. Discussing these requirements with your supplier is essential to balance performance needs with budget constraints.

Essential Post-Processing and Finishing for Hot-Pressed SiC Components

While hot pressing aims to produce near-net-shape parts, most high-performance SiC components require some form of post-processing or finishing to meet final specifications for dimensions, surface quality, or enhanced properties.

Common post-processing steps for hot-pressed SiC include:

- Diamond Grinding:

- Purpose: The most common machining process for SiC. Used to achieve precise dimensional tolerances, flatness, parallelism, roundness, and specific surface finishes.

- Techniques: Includes surface grinding, cylindrical grinding (ID/OD), centerless grinding, and creep-feed grinding. Requires specialized diamond grinding wheels and machinery.

- Lapping and Polishing:

- Purpose: To achieve ultra-smooth surface finishes (low Ra values), high levels of flatness, and parallelism, particularly for sealing surfaces, optical components, and semiconductor equipment parts.

- Process: Involves using progressively finer diamond abrasives on a lapping plate. Polishing may use even finer abrasives or chemical-mechanical polishing (CMP) techniques for mirror finishes.

- Cutting and Dicing:

- Purpose: To cut larger hot-pressed blanks into smaller pieces or to create specific features like slots or grooves.

- Tools: Diamond-impregnated saws or laser cutting (for thinner sections or specific applications).

- Drilling:

- Purpose: To create holes for assembly, fixturing, or fluid passage.

- Methods: Diamond core drilling, ultrasonic drilling, or laser drilling. Due to SiC’s brittleness, careful control of drilling parameters is essential to prevent chipping or cracking.

- Edge Chamfering/Radiusing:

- Purpose: To remove sharp edges, which can be prone to chipping and are potential stress concentrators. Improves handling safety and component durability.

- Methods: Manual or automated grinding with profiled diamond wheels.

- Cleaning:

- Purpose: To remove any residues from machining coolants, handling, or the manufacturing environment. Critical for high-purity applications like semiconductor components.

- Methods: Ultrasonic cleaning with specific solvents, deionized water rinses, and cleanroom packaging.

- Coatings (Less Common for Hot-Pressed SiC but Possible):

- Purpose: In some specialized cases, coatings (e.g., CVD SiC, diamond-like carbon) might be applied to further enhance surface properties like wear resistance or chemical compatibility, though hot-pressed SiC inherently possesses excellent properties.

- Annealing:

- Purpose: Occasionally used to relieve internal stresses induced during aggressive grinding, though less common than for metals.

The extent and type of post-processing are determined by the application’s requirements. It’s a significant cost driver, so careful specification is necessary. Partnering with a supplier with comprehensive in-house finishing capabilities ensures better quality control and lead times.

Navigating Common Challenges in SiC Hot Pressing and Their Solutions

Manufacturing high-quality hot-pressed SiC components is a complex process with several potential challenges. Understanding these and how experienced manufacturers overcome them is crucial for technical buyers.

- Brittleness and Machining Complexity:

- Challenge: SiC is very hard but also brittle, making it susceptible to chipping, cracking, or fracture during machining and handling if not done correctly.

- Solutions:

- Employing experienced machinists trained in handling hard ceramics.

- Using appropriate diamond tooling, optimized cutting speeds, feeds, and depth of cut.

- Rigid machine setups to minimize vibration.

- Careful part handling and fixturing.

- Designing parts with features that minimize stress concentrations (e.g., rounded corners).

- Achieving Full Densification and Uniformity:

- Challenge: Ensuring consistent high density throughout the component, especially for large or complex shapes, can be difficult. Non-uniform density can lead to variations in properties.

- Solutions:

- Precise control over SiC powder characteristics (particle size distribution, purity).

- Optimal selection and homogeneous mixing of sintering aids.

- Careful die design to ensure uniform pressure distribution.

- Accurate temperature control and programming of the hot press cycle.

- Advanced process monitoring and quality control.

- Thermal Shock Sensitivity (Relative to Metals):

- Challenge: While SiC has good thermal shock resistance compared to many other ceramics, rapid, extreme temperature changes can still induce stress and potential cracking, especially if internal flaws are present.

- Solutions:

- Ensuring high density and minimal porosity to reduce internal defect sites.

- Designing components to minimize thermal gradients during operation.

- Selecting appropriate SiC grades with optimized thermal shock parameters.

- Controlled heating and cooling rates during manufacturing and in application where possible.

- Tooling Costs and Wear:

- Challenge: Graphite dies used in hot pressing have a limited lifespan due to the high temperatures and pressures involved, and can be complex and expensive to manufacture, especially for intricate part geometries.

- Solutions:

- Utilizing high-quality graphite grades for dies.

- Optimizing die design for longevity and ease of replacement.

- Efficient hot pressing cycles to maximize throughput per die.

- Amortizing tooling costs over larger production volumes where feasible.

- Designing parts for manufacturability to simplify tooling.

- Cost of Raw Materials and Processing:

- Challenge: High-purity SiC powders and the energy-intensive hot pressing process contribute to a higher component cost compared to some conventional materials.

- Solutions:

- Optimizing material usage and minimizing waste through near-net-shape hot pressing.

- Efficient process controls to reduce energy consumption.

- Focusing on applications where the superior performance and extended lifespan of SiC justify the initial investment (Total Cost of Ownership).

- Sourcing from regions with established SiC manufacturing ecosystems for competitive pricing, such as Weifang, China.

Overcoming these challenges requires a deep understanding of materials science, process engineering, and precision manufacturing techniques, which are hallmarks of a reliable SiC component supplier.

Choosing Your SiC Hot Pressing Partner: The CAS New Materials (SicSino) Advantage

Selecting the right supplier for your custom hot-pressed silicon carbide components is a critical decision that directly impacts component quality, performance, lead times, and overall project success. Beyond technical specifications, you need a partner with proven expertise, robust capabilities, and a commitment to quality.

Key factors to consider when evaluating a supplier:

- Technical Expertise & Experience: Assess their knowledge of SiC materials science, hot pressing technology, and application engineering. How long have they specialized in SiC? Can they provide material selection guidance?

- Manufacturing Capabilities: Do they have modern hot pressing equipment? What are their capabilities for powder preparation, tooling design and fabrication, precision machining, and finishing?

- Quality Management Systems: Are they certified to relevant quality standards (e.g., ISO 9001)? What are their quality control procedures from raw material inspection to final part verification?

- Customization Capabilities: Can they truly tailor solutions, from material formulation to complex geometries, to meet your unique requirements? Look for evidence of successful

SicSino – CAS new materials

We, CAS new materials(SicSino), have been introducing and implementing silicon carbide production technology since the 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.